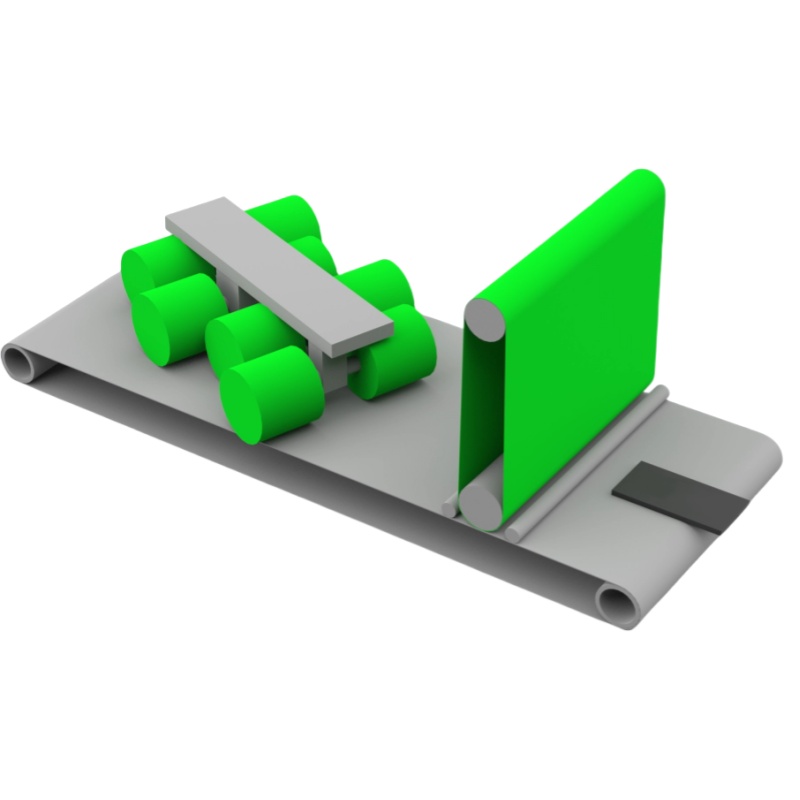

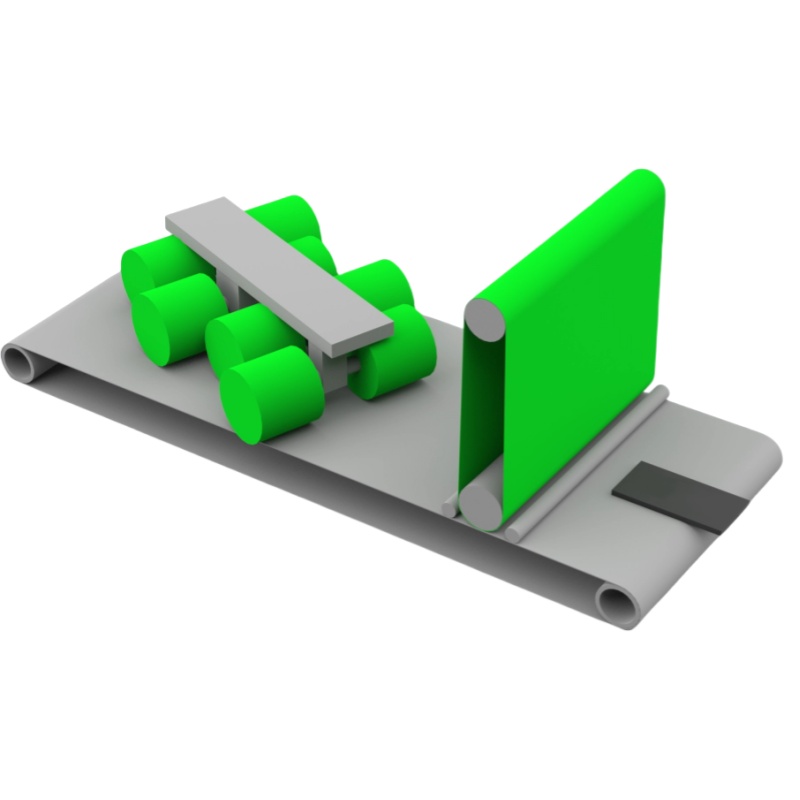

1350mm Deburring and Edge Rounding Machine

Functions & Applications

The 1350mm deburring and edge rounding machine is designed to remove burrs and round sharp edges from metal parts after flame cutting, ensuring smooth and safe surfaces. It is suitable for various industries, including:

Metal Fabrication – Smoothing flame-cut parts for better assembly

Automotive & Aerospace – Ensuring precision and safety in metal components

Machinery & Equipment Manufacturing – Preparing parts for coating and painting

Steel & Aluminum Processing – Refining rough edges for improved durability

Key Features:

✔ Deburring & Edge Rounding in a single process

✔ Handles Various Materials – Steel, aluminum, stainless steel

✔ High Precision – Servo-controlled adjustments for consistency

✔ Adjustable Conveyor & Brush Speed for different processing needs

✔ Magnetic & Vacuum Holder Options for various workpieces

✔ Efficient Dust Extraction System for a cleaner work environment

Technical Specifications

| Specification | Details |

| Material Compatibility | Steel, Aluminum, Stainless Steel |

| Processes | Deburring, Edge Rounding |

| Material Thickness | 0.5 - 80mm |

| Max Material Width | 1350mm |

| Min Part Size | 50mm × 50mm |

| Max Material Weight | 600kg |

| Conveyor Speed | 0.5 - 6.0 m/min (Adjustable) |

| Holding System | Magnetic (Vacuum Optional) |

| Total Machine Power | 50KW |

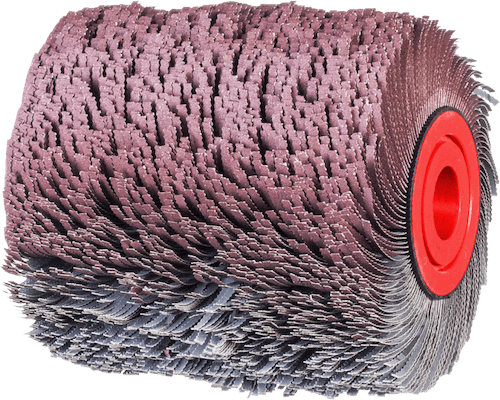

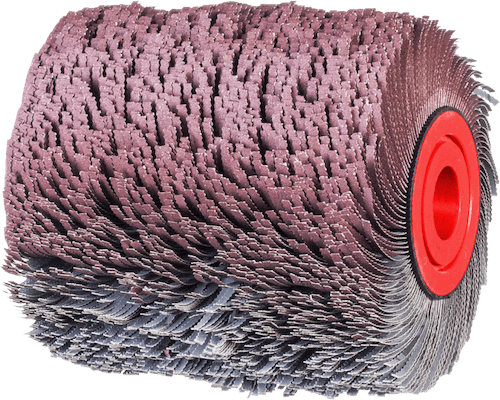

| Flap Wheels Quantity | 6 pcs |

| Flap Wheels Dimensions | Ø300 × 400mm |

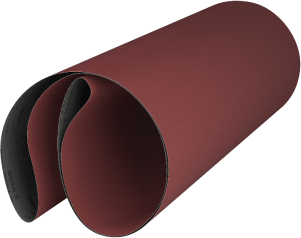

| Sand Belt Size | Φ1910mm × 1350mm |

| Disc Brush Size | Ø300mm × 400mm |

| Sand Belt Linear Speed | 18 m/s |

| Disc Brush Rotation Speed | 8 - 26 m/s (Adjustable) |

| Disc Brush Revolution Speed | 1 - 15 r/min (Adjustable) |

| Planetary Revolution Heads | 1 pcs |

| Planetary Rotation Heads | 8 pcs |

| Processing Thickness Adjustment Precision | 0.01mm |

| Brush Compensation Adjustment Precision | 0.01mm |

| Grinding Consumables | Sand Belt + Rotary Brush |

| Dust Extraction Volume | 5000 m³/h |

| Machine Dimensions (L×W×H) | 3800mm × 2300mm × 2400mm |

| Machine Weight | Approx. 5T |

Consumables Used:

Flap Wheels

Ceramic Emery Band – For aggressive material removal

Zirconium Emery Band – Durable and suitable for heavy-duty applications

Aluminum Oxide Emery Band – General-purpose use with balanced performance

Cubitron Emery Band – Precision grinding and extended lifespan

Scotch Emery Band – Fine finishing and surface preparation