| Processing Materials | Stainless steel, carbon steel, aluminum plate, copper plate, various non-ferrous metals |

| Processing Width | ≤1330mm |

| Processing Thickness | 0.5~80mm |

| Minimum Processing Size | 50mm × 50mm (For non-perforated workpieces) |

| Total Machine Power | 45.5KW (Excluding dust collection system) |

| Feeding Speed | 0.5~6m/min (Adjustable via frequency converter) |

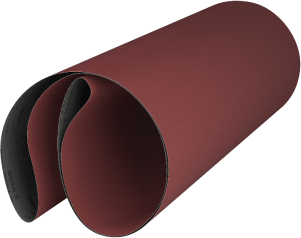

| Abrasive Belt Speed | Approx. 18m/s |

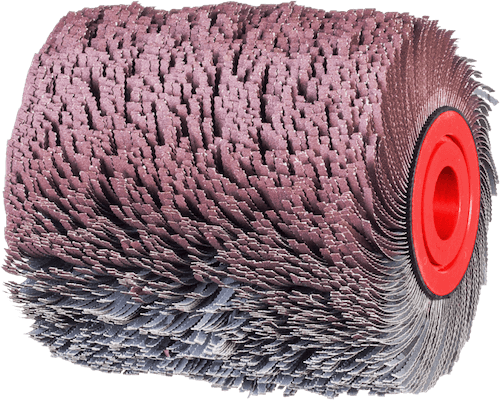

| Rotary Brush Self-Rotation Speed | 8~26m/s (Adjustable via frequency converter) |

| Rotary Brush Orbital Rotation Speed | 1~15r/min (Adjustable via frequency converter) |

| Planetary Rotary Brush Orbiting Heads | 1 |

| Planetary Rotary Brush Self-Rotating Heads | 8 |

| Servo Adjustment Precision for Processing Thickness | 0.01mm |

| Servo Adjustment Precision for Brush Compensation | 0.01mm |

| Abrasive Consumables | Steel hammer disk brush + abrasive belt + rotary brush |

| Dust Extraction Volume | 5000m³/h |

| Machine Dimensions | L4500mm × W2300mm × H2500mm |

| Total Machine Weight | Approx. 6T |