| Material | Steel, Aluminum, Stainless Steel |

| Process | Heavy Slag Removal, Deburring, Edge Rounding, Satin Finishing |

| Max Material Weight | 600 kg |

| Processing Width | ≤ 1330 mm |

| Processing Thickness | 0.5 ~ 80 mm |

| Min. Processing Size | 50 mm x 50 mm (for flat parts, thickness 0.5 ~ 10 mm) |

| Total Power | 45.5 kW (without dust collection) |

| Hammer Disc Brush Diameter | Φ162 mm |

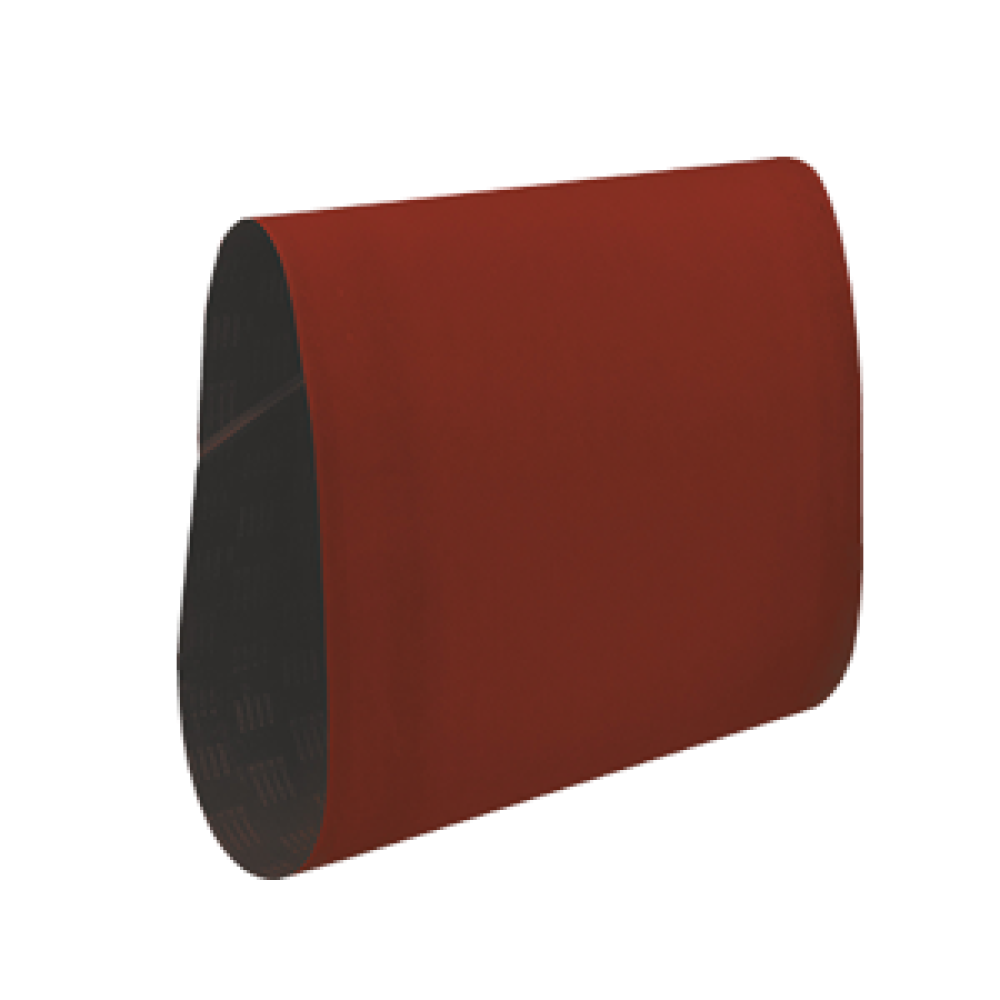

| Sanding Belt Dimensions | Φ1910 mm x 1350 mm |

| Brush Diameter | Φ300 mm x 400 mm |

| Conveyor Feeding Speed | 0.5 ~ 6 m/min (Variable Frequency) |

| Sanding Belt Speed | Approx. 18 m/s |

| Brush Rotation Speed (Self Rotation) | 8 ~ 26 m/s (Variable Frequency) |

| Brush Revolution Speed (Planetary Rotation) | 1 ~ 15 rpm (Variable Frequency) |

| Brush Planetary Axial Head Count | 1 |

| Brush Planetary Self-Rotation Head Count | 8 |

| Thickness Servo Adjustment Precision | 0.01 mm |

| Brush Compensation Servo Adjustment Precision | 0.01 mm |

| Grinding Consumables | Hammer Disc Brush, Sanding Belt, Brushes |

| Dust Collection Airflow | 5000 m³/h |

| Holder System | Magnetic (Vacuum Optional) |