The MSP-DL1350 Slag Removal, Deburring, and Edge Rounding Machine is a robust, versatile, and highly efficient system designed for applications involving carbon steel workpieces such as pipe racks, bridges, and lattice towers. Below is a detailed summary of its features and technical specifications:

1. Main Features

Processing Applications

Suitable for carbon steel.

Removes burrs from stamping, shearing, laser cutting, plasma cutting, and flame cutting.

Performs slag removal, brushing, deburring, polishing, and edge rounding with an adjustable R-radius.

Equipment Highlights

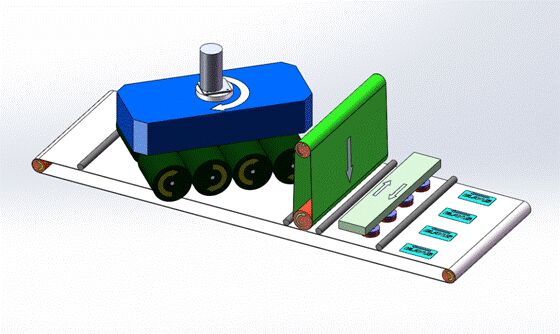

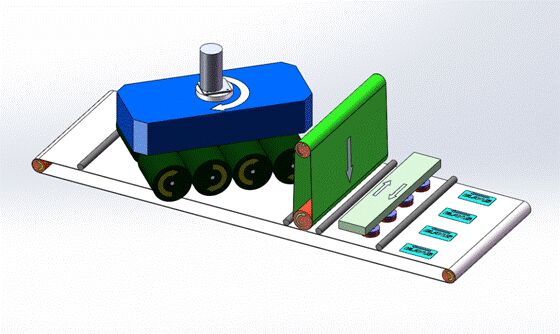

2. Working Principle

Step 1: Slag and burrs are struck off using horizontally oscillating steel hammer disc brushes.

Step 2: Surface burrs are smoothed using a sanding belt station.

Step 3: Edges and inner holes are processed by multi-directional disc roller brushes that revolve and rotate, ensuring uniform finishing and edge rounding.

This through-feed process allows simultaneous deburring and edge rounding for all sides and holes in a single pass.

3. Technical Specifications

| Parameter | Value |

| Processing Width | ≤1330mm |

| Processing Thickness | 0.5~80mm |

| Minimum Processing Size | 50mm × 50mm |

| Machine Power | 45.5 KW |

| Sand Belt Size | Φ1910mm × 1350mm |

| Disc Brush Size | Φ300mm × 400mm |

| Conveyor Speed | 0.5~6 m/min, adjustable |

| Sand Belt Linear Speed | 18 m/s |

| Disc Brush Rotation Speed | 8~26 m/s, adjustable |

| Disc Brush Revolution Speed | 1~15 r/min, adjustable |

| Brush Head Configuration | 1 planetary + 8 rotating |

| Thickness Adjustment Precision | 0.01mm |

| Grinding Consumables | Hammerhead disc + abrasive belt + rotary brush |

| Dust Extraction Volume | 5000 m³/h |

| Equipment Dimensions | 4500mm × 2300mm × 2500mm |

| Weight | 6T |

4. Advantages

High Production Efficiency: Continuous feed design supports large-scale production.

Superior Quality: Delivers consistent and precise finishing results.

Cost-Effectiveness: Significantly reduces processing costs compared to manual methods.

Enhanced Safety: The wet dust collection system ensures a cleaner, safer work environment.

Adaptability: Can handle a wide variety of workpiece sizes and shapes with or without fixtures.