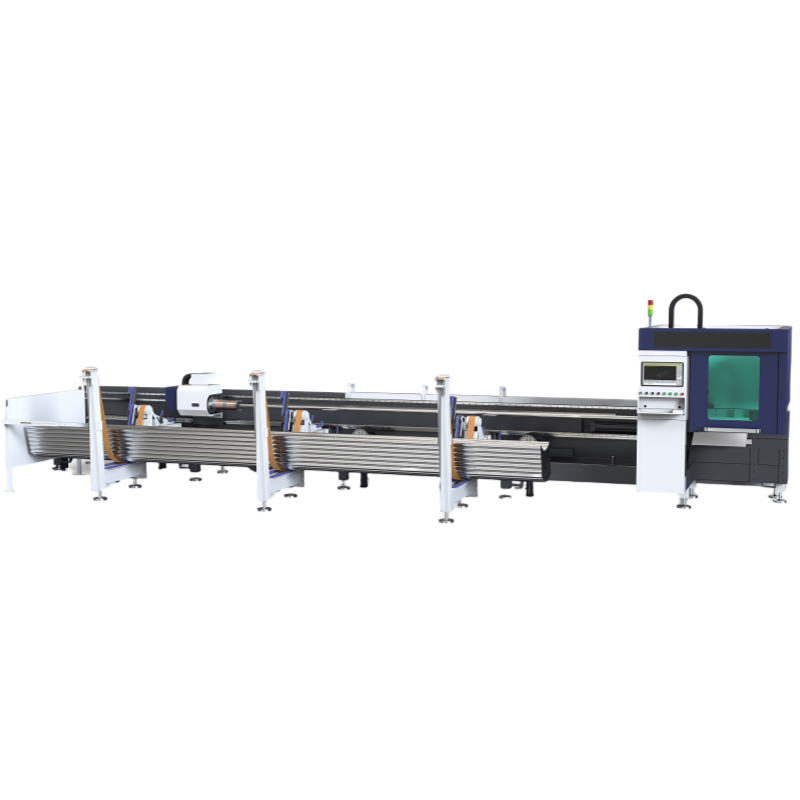

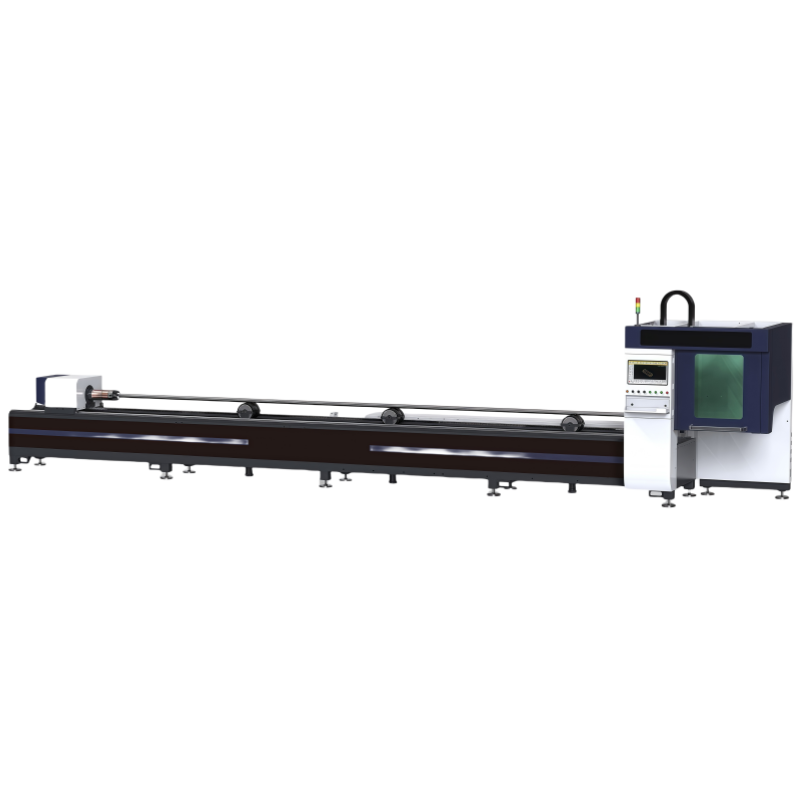

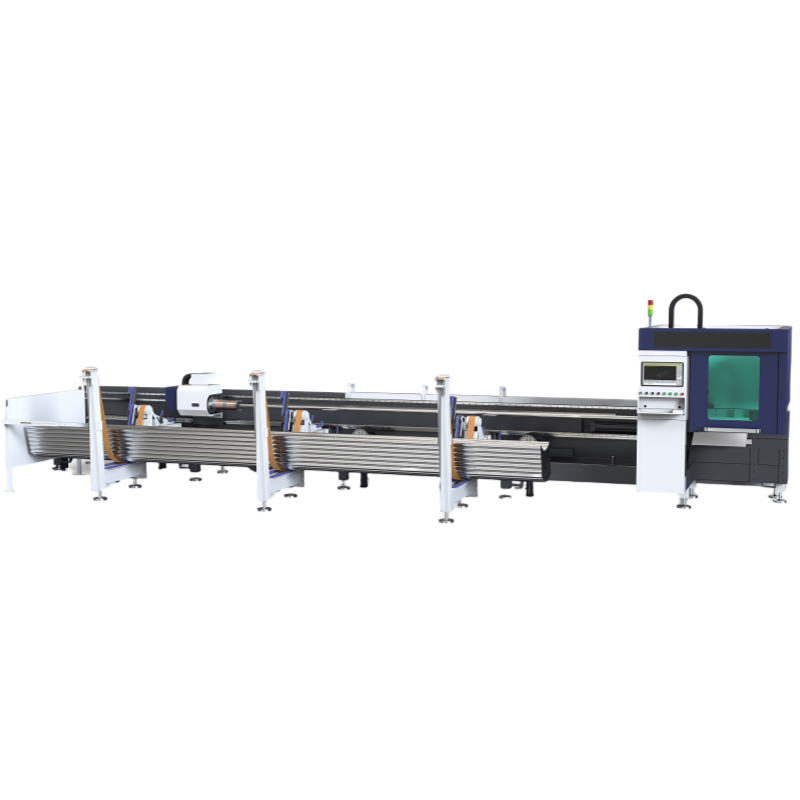

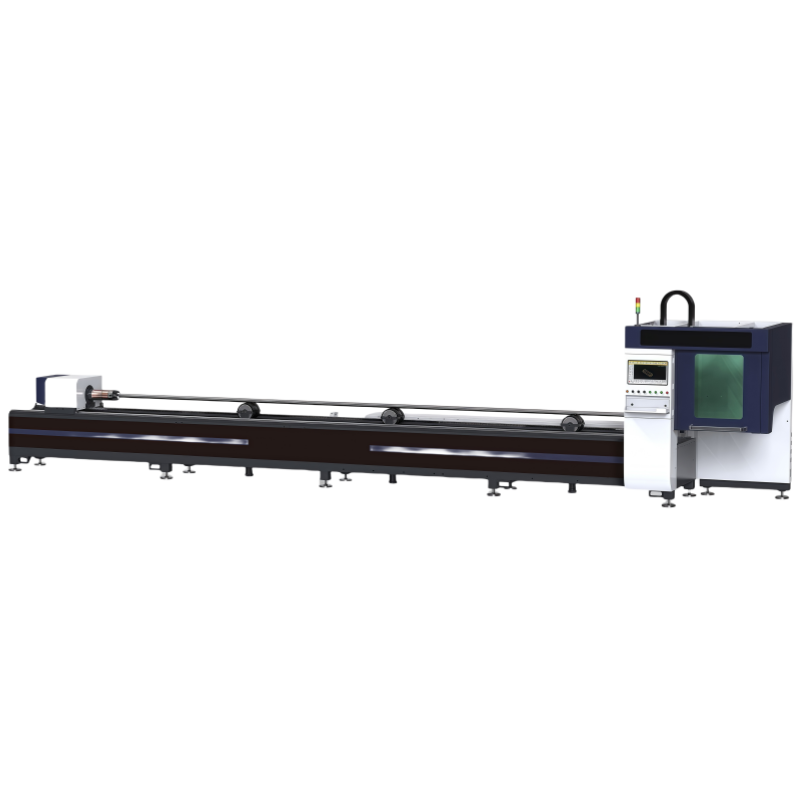

The G120K/G170K/G240K 3D Laser Tube Cutting Machine is designed for high-performance, precise cutting and beveling of tubes using advanced CNC laser technology. Here's an overview based on the detailed information you provided:

Key Features:

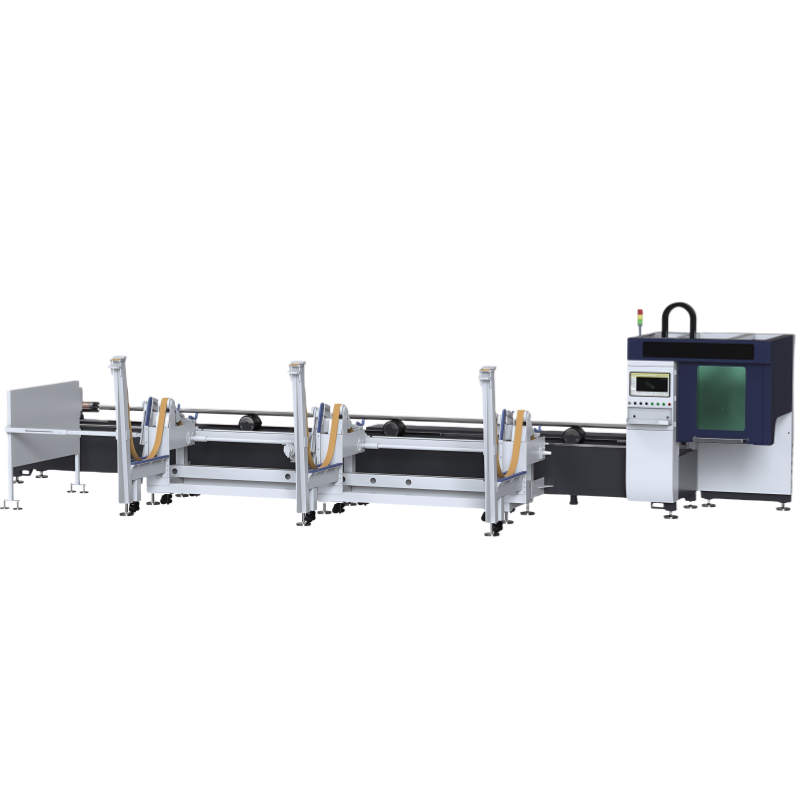

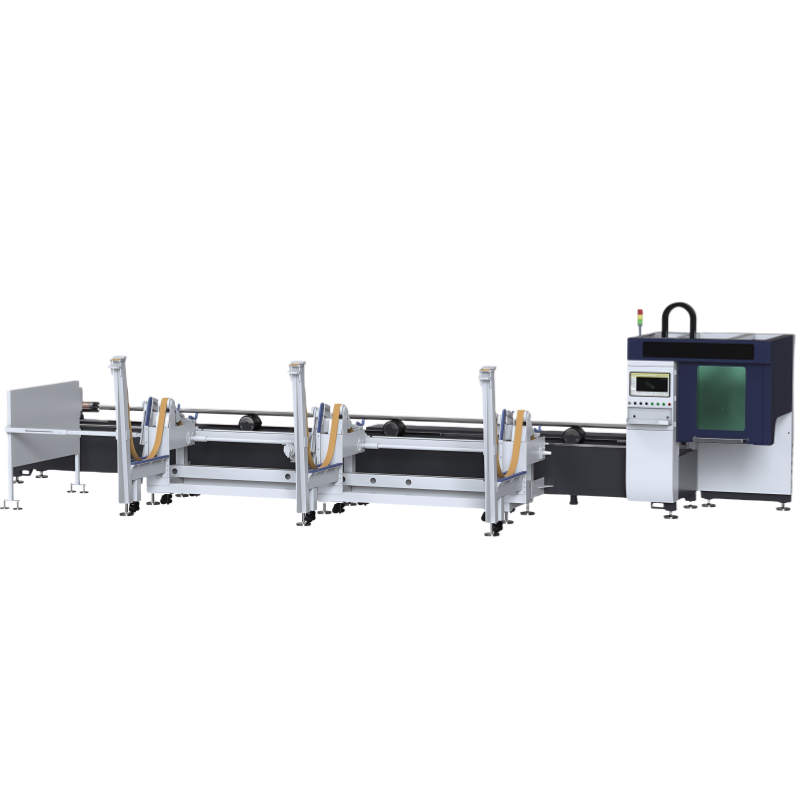

Fully Automatic Loading System:

High Efficiency:

Minimal Scrap and Material Savings:

Small blind zone for residual scrap, reducing material waste and improving efficiency.

The remaining scrap length can be controlled precisely, even to zero, saving materials.

Adaptive Cutting:

Compact Design:

Laser Generator:

High-quality lasers from Chuangxin or Raycus, with stable performance and modular design.

The generator supports direct replacement and upgrades, minimizing downtime.

Fiber Laser Cutting Head:

Features advanced technology with modular design and compatibility with various fiber lasers (e.g., QBH and QCS interfaces).

High adaptability and excellent cutting quality.

Precision Chuck:

Transmission System:

Gear and rack drive system with imported precision ball screw for high-speed, high-precision, and reliable operation.

Anti-dust features protect the transmission system, ensuring longevity and maintaining accuracy.

Cooling System:

Equipped with high-quality Hanli brand cooling units, ensuring stable temperature control for laser operation.

The system also ensures effective cooling for lenses, preventing damage due to condensation.

Gas Control System:

Features independent control for cutting gases like air, nitrogen, and oxygen, allowing for flexible cutting process adjustments.

Advanced Servo Control:

G120K / G170K / G240K 3D Laser Pipe Cutting Machine Technical Specifications

| Model | G120K | G170K | G240K |

| Laser Power (W) | 1500-6000 | 1500-6000 | 1500-6000 |

| Cutting Pipe Diameter (MM) | Φ: 10-120, □: 10-120 | Φ: 10-170, □: 10-170 | Φ: 10-240, □: 10-240 |

| Repeat Positioning Accuracy (MM) | ±0.02 | ±0.02 | ±0.02 |

| Pipe Processing Range (MM) | ≈6250 | ≈6250 | ≈6250 |

| Machine Dimensions (MM) | LWH: 887417202175 | LWH: 887417202175 | LWH: 887417202175 |

| Machine + Material Rack Dimensions (MM) | Semi-auto: 885621702175, Fully-auto: 885629492175 | Semi-auto: 885621702175, Fully-auto: 885629492175 | Semi-auto: 885621702175, Fully-auto: 885629492175 |

| Machine Weight (T) | ≈3.5 | ≈3.5 | ≈4.5 |

| Acceleration (G) | ≈1.6 | ≈1.3 | ≈1.0 |

| Waste Length (MM) | ≈40 | ≈80 | ≈100 |

Accessory Configuration List

| No. | Name | Brand/Origin | Model/Specification | Quantity | Remarks |

| 1 | Laser | Chuangxin/Raycus | Fiber Laser | 1 set |

|

| 2 | Cutting Head | Ospri | Fiber Laser Cutting Head | 1 set |

|

| 3 | Control System | Bystronic | Fiber Control System | 1 set |

|

| 4 | Rotary Pneumatic Chuck | Biote/Other options | - | 1 set |

|

| 5 | X.Y.Z Axis Slider | SHAC/AirTAC | - | 3 sets |

|

| 6 | X.Y.Z Axis Guide Rail | SHAC/AirTAC | - | 3 sets |

|

| 7 | X.Y Axis Rack | Taiwan Liangchi/Taiwan Jinte | - | 2 sets |

|

| 8 | X.Y.Z.U Axis Servo Motors and Drivers | Delta/Inovance | - | 4-5 sets |

|

| 9 | Pneumatic System | AirTAC | - | Several |

|

| 10 | Electric Proportional Valve | AirTAC/SMC | - | 1 piece |

|

| 11 | Machine Accessories | Standard | - | 1 set |

|

| 12 | Machine Bed | Standard | - | 1 unit |

|

| 13 | Control Cabinet | Standard | - | 1 set |

|

| 14 | Circuit Breaker, Relay | Schneider/DELIXI | - | 1 set |

|

| 15 | Power Supply | Schneider/DELIXI | - | 1 set |

|

| 16 | Cooling System | Hanli | - | 1 set |

|

| 17 | Loading System | Fully-auto/Semi-auto Material Rack | - | 1 set |

|

Consumables and Specialized Parts List

| No. | Name | Specification | Unit | Quantity | Remarks |

| 1 | Optical Lens | Ospri | Piece | 5 |

|

| 2 | Cutting Nozzle | Ospri | Piece | 5 |

|

| 3 | Ceramic Ring | Ospri | Piece | 5 |

|

Equipment Usage Analysis

Fiber Laser Environment Requirements: Temperature 15-35℃, Relative Humidity < 85%.

On-site Power Distribution Requirements: 380V 50Hz, with short circuit protection and others.

Grounding Requirements: Dedicated grounding system with a grounding resistance of no more than 4Ω.

Lifting Equipment: Necessary lifting equipment and personnel should be provided.

Materials for Equipment Installation: Provide required materials such as steel plates for installation and debugging.

Auxiliary Conditions for Laser Cutting:

Cutting Auxiliary Gases: Nitrogen (N2), Oxygen (O2).

Dry, oil-free compressed air system.

Foundation Requirements: Concrete foundation, minimum thickness of 300mm, free from vibration sources or with vibration damping grooves around the foundation.

Equipment Voltage and Gas Requirements

| No. | Name | Specification |

| 1 | Rated Input Voltage | 380V/50Hz, Voltage Stability: ±5% (Recommended to use a voltage stabilizer). |

| 2 | Compressed Air Supply System | Rated Pressure: High pressure ≥1.6Mpa, Low pressure ≥0.6Mpa, Air Flow: >1.0m³/min, Volume: 1m³. |

| 3 | Auxiliary Gas | Nitrogen (N2) ≥99.99%, Compressed Air ≥1.6Mpa. |

Let me know if you need further clarification or additional details!

Technical Specifications:

Model Options: G120K, G170K, G240K

Cutting Range: Tubes and pipes of various sizes, with customized configurations available.

Max Cutting Speed: Enhanced for rapid tube cutting.

Laser Source Power: Variable, depending on the laser generator used.

Precision: 0.01mm repeat positioning accuracy.

Cutting Gas: Air, Nitrogen, Oxygen (optional).

Cooling System: Advanced water-cooled system with temperature control for both the laser and optical components.

Automation: Fully automated loading and unloading systems for increased efficiency.

Applications:

Industrial Use: Suitable for manufacturing sectors such as 3C, automotive, medical, aerospace, and more.

Precision Cutting: Ideal for cutting and beveling pipes with precision and speed.

Wide Applications: Compatible with a variety of materials such as stainless steel, aluminum, and non-ferrous metals.

Operational Cost Analysis:

The machine is designed to minimize material wastage, which can significantly reduce operational costs in tube cutting processes. With its high-speed operation and reduced maintenance requirements, it offers a low-cost per part production and ensures long-term efficiency.