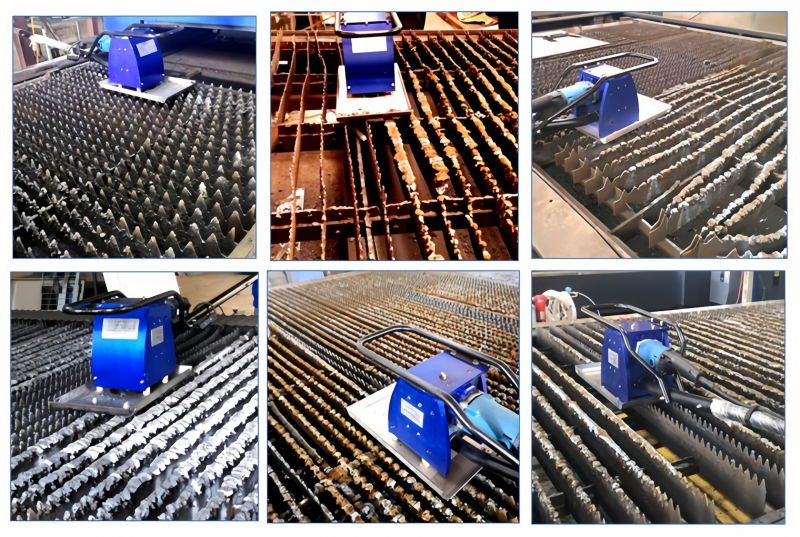

High-Power Cleaning: The 1600W power output ensures optimal cleaning performance, efficiently removing slag, metal dust, and other residue that typically accumulate on laser cutting slats.

Slag Removal Function: In addition to cleaning the slats, the machine also features an integrated slag removal function that targets and removes slag build-up, ensuring that the slats remain clean and level for precise cutting.

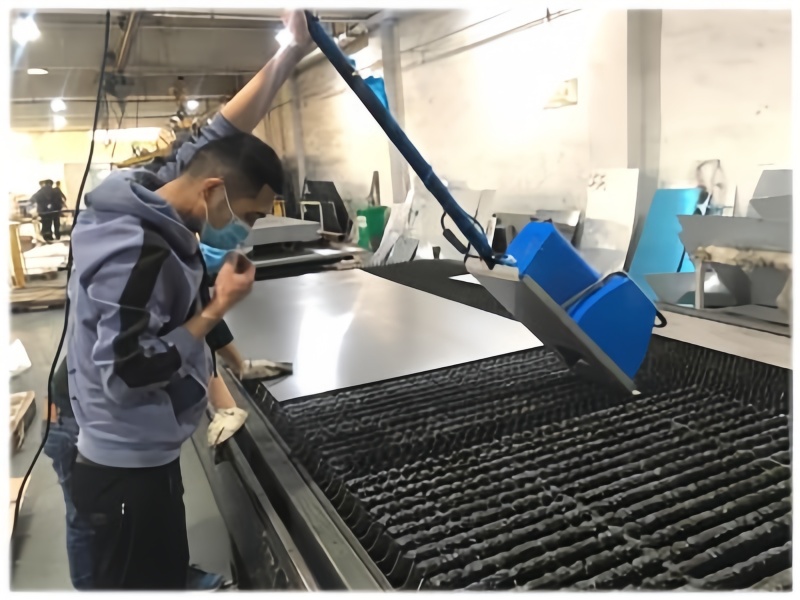

Automatic and Easy Operation: Designed for ease of use, this slat cleaner operates automatically, requiring minimal user intervention. It significantly reduces downtime, enhances productivity, and eliminates the need for manual cleaning.

Precision Cleaning: Equipped with a specialized cleaning head and adjustable settings, the machine ensures thorough cleaning even in difficult-to-reach areas, providing consistent results across the entire slat surface.

Durable and Robust Construction: Built to withstand the rigors of industrial environments, the 1600W slat cleaning machine features high-quality components that offer long-term reliability and performance.

Improved Cutting Efficiency: Regular cleaning helps maintain a clean, level surface for laser cutting, improving the heat dissipation process and ensuring better cutting accuracy and edge quality.

Reduced Maintenance Costs: By preventing the build-up of slag and debris, this machine helps to extend the life of the laser cutting table and reduces the frequency of costly maintenance or repairs.

User-Friendly Interface: Featuring a simple control panel and intuitive operation, the machine is easy to use, even for operators with minimal technical experience.