1.1 Summary

Laser welding is an advanced welding method and an important application of laser material processing technology.

This equipment is mainly designed for thin-walled materials and precision parts, using a heat conduction welding process.

Laser radiation heats the workpiece surface, and the heat is conducted inward. By controlling pulse width, energy, peak power, and repetition frequency, the workpiece melts to form a molten pool.

Applicable welding methods:

Spot welding

Butt welding

Overlay welding

Sealing welding

Key features:

High depth-to-width ratio, narrow weld seams, small heat-affected zone, minimal deformation

Fast welding speed; smooth and aesthetic weld seam

No or minimal post-processing required

High weld quality, no porosity

Precise control, high positioning accuracy, easy automation

1.2 Main Technical Features

Laser spot becomes more uniform and stable after fiber transmission, improving weld quality

Focused laser spot is small with high power density and precise positioning, optimized for mold repair

Dedicated water chiller ensures long-term, high-power welding stability

Gas protection system continuously provides argon protection during welding to preserve product color and enhance quality

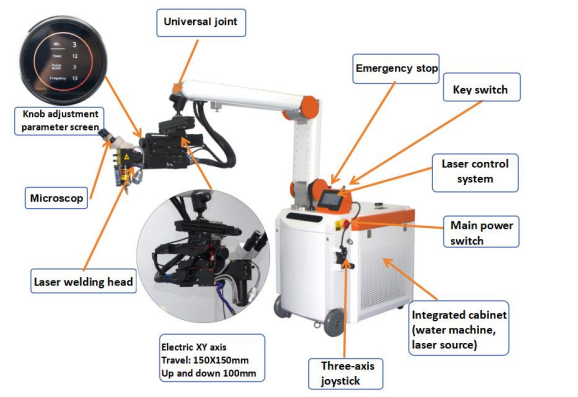

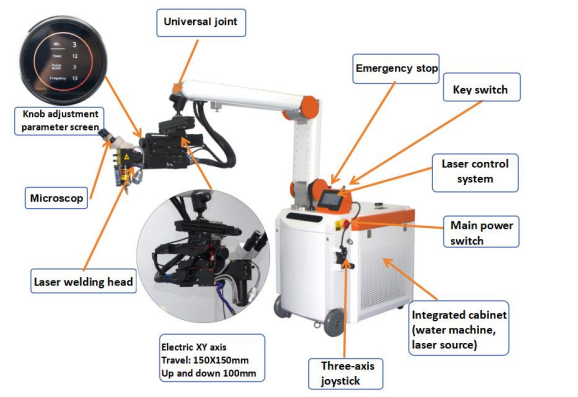

Dual-joint articulated arm design with universal wheels and three-axis joystick allows flexible angle adjustment, ideal for large mold repair

Joystick controls the translation stage, enabling easy repair of large and extra-large molds without moving them

Laser head can rotate 360° and move electrically up and down, convenient for side welding

Dedicated welding control system with high stability; LCD touchscreen is easy to operate and learn

Strong expandability; can integrate with production lines, photoelectric sensors, and pneumatic fixtures for fully automated processing

1.3 Advantages Compared to Traditional Pulsed Mold Welding

No consumables (no lamps), maintenance-free

Lower energy consumption

Wider fusion range: effective for stainless steel 0.1–1.0 mm; laser is stable without beam wandering

High stability: dedicated water chiller supports long-term high-power welding

Water-cooled optics: protects lenses during long-term high-power operation

High weld quality: deep welds, strong bonding, full melting, no pores or sand holes, aesthetic repair traces

1.4 Product Models and Technical Specifications

| No. | Parameter | 1500W-GQMJ | 2000W-GQMJ |

| 1.4.1 | Maximum Laser Power | 1500 W | 2000 W |

| 1.4.2 | Laser Type | Fiber laser, conventional QBH terminal | Fiber laser, conventional QBH terminal |

| 1.4.3 | Laser Wavelength | 1080 ±10 nm | 1080 ±10 nm |

| 1.4.4 | Motion Mode | Continuous / Pulse | Continuous / Pulse |

| 1.4.5 | Maximum Adjustment Frequency | 25 Hz (customizable) | 25 Hz (customizable) |

| 1.4.6 | Laser Welding Depth | ≤ 2.0 mm (depending on material) | ≤ 2.5 mm (depending on material) |

| 1.4.7 | Fiber Core Diameter | 50 μm | 50 μm |

| 1.4.8 | Fiber Length | > 8 m | > 8 m |

| 1.4.9 | Output Mode | QCW / PWM / CW | QCW / PWM / CW |

| 1.4.10 | Positioning System | Microscope | Microscope |

| 1.4.11 | Rated Power | 5.6 kW | 6.4 kW |

| 1.4.12 | Cooling Method | Water-cooled | Water-cooled |

| 1.4.13 | Power Requirement | 220V ±10%, 50Hz, 40A | 220V ±10%, 50Hz, 40A |

| 1.4.14 | 3D Worktable Load | ≤100 kg | ≤100 kg |

| 1.4.15 | Main Machine Dimensions (L×W×H) | 900×900×1150 mm | 900×900×1150 mm |

| 1.4.16 | Net Weight | 300 kg | 320 kg |

| 1.4.17 | 3D Worktable Dimensions / Weight | 600×450×610 mm / 36 kg | 600×450×610 mm / 36 kg |

1.5 Working Environment Requirements

Ambient temperature: 5℃–35℃ (air conditioning recommended)

Humidity: 40%–80%, no condensation (dehumidifier recommended)

Power supply fluctuation: <5%; for areas with >5% fluctuation, install automatic voltage stabilizer

Foundation vibration: amplitude <50 μm; acceleration <0.05 g; avoid large stamping machines nearby

Air pressure: 86–106 kPa

Environment:

No strong electromagnetic interference; avoid radio transmitters or relay stations

Dust-free and smoke-free workspace; avoid metal polishing powder environment

Anti-static flooring recommended; equipment grounded

If ambient temperature <0℃, add antifreeze to water; drain water when equipment is not in use

1.6 Machine Structure and Working Principle

The welding machine consists of laser power supply, optical system, cooling system, and 3D worktable.

It uses high-energy pulsed laser for welding.

Working principle:

Fiber laser emits pulsed laser with 1080 nm wavelength

Laser passes through transmission, beam expansion, and focusing to act on the workpiece

Frequency and pulse width are controlled by microcontroller to adjust power and energy for precise welding