1. Product Overview

1.1 Summary

Laser welding is a cutting-edge technology in laser material processing, specialized in welding thin-walled components and precision parts. It uses a heat conduction welding method, where laser radiation heats the workpiece surface and thermal energy penetrates the material via conduction.

By precisely controlling parameters such as pulse duration, energy intensity, peak power, and repetition rate, it forms controlled molten pools for:

Spot welding

Butt welding

Lap welding

Seal welding

Advantages of this process:

High depth-to-width ratio, narrow weld seams

Minimal heat-affected zone and deformation

Fast operation with smooth weld surfaces

Post-welding maintenance-free or low-maintenance

Focused light beams and high positioning accuracy

Seamless integration into automated workflows

1.2 Main Technical Features

Stable and uniform laser spot after fiber transmission improves weld quality

Small focused spot with high power density, optimized for mold repair

Special chiller ensures stable long-term high-power welding

Gas protection system maintains product color and weld quality with argon protection

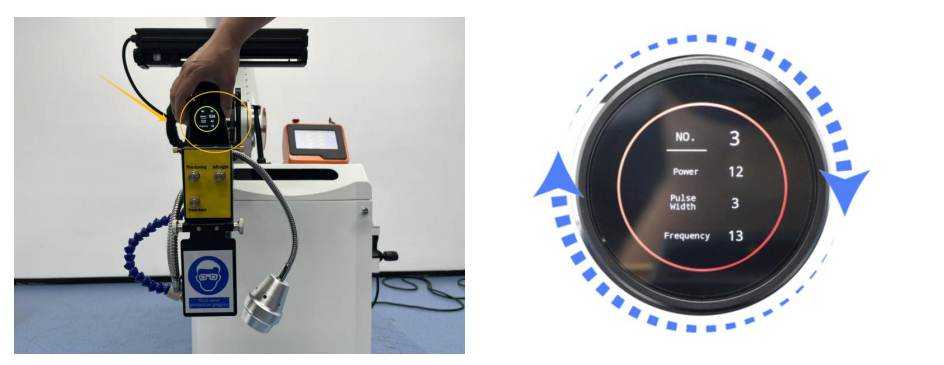

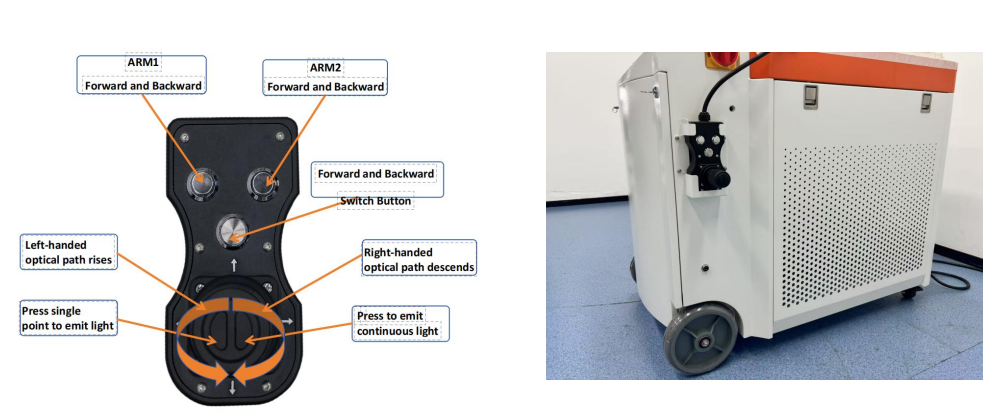

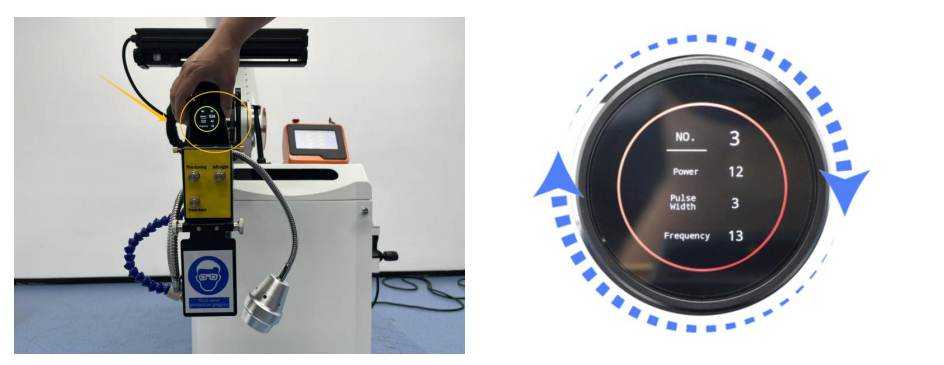

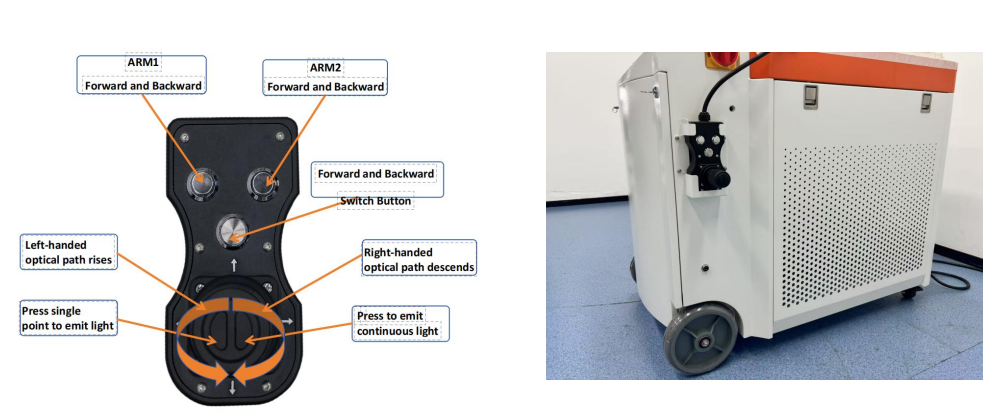

Double-joint boom with swivel casters and three-axis rocker arm allows flexible movement without moving the mold

360° laser head rotation and electric lift enable welding on all sides

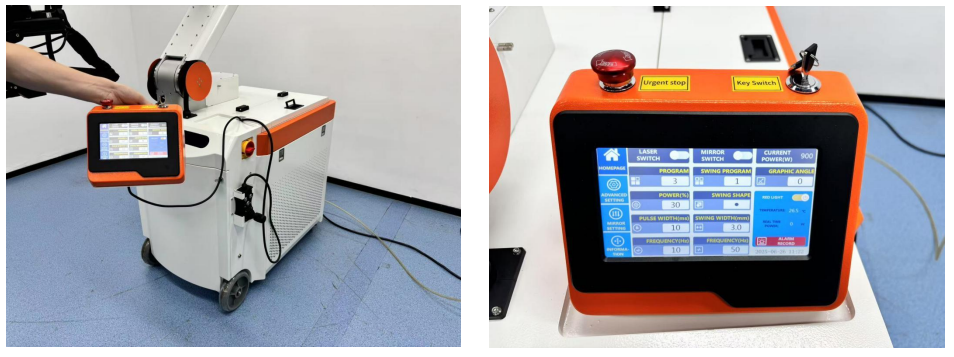

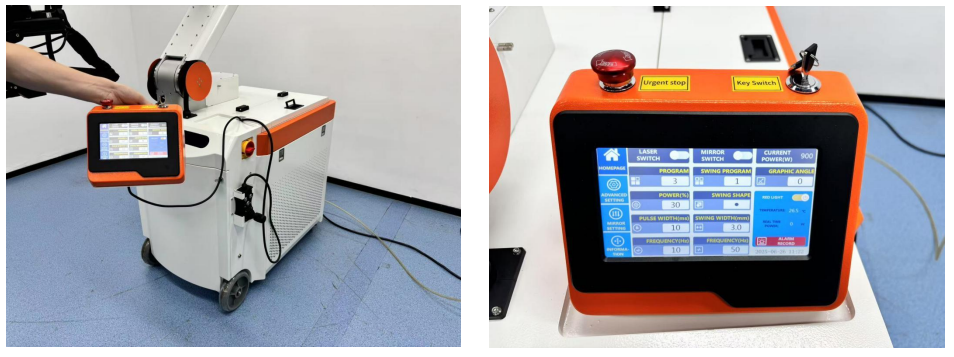

Dedicated welding control system with LCD touchscreen: easy to operate and learn

Expandable system compatible with automation devices such as production lines, photoelectric detectors, and pneumatic fixtures

1.3 Advantages Over Traditional Pulse Mold Welding

No consumables (no tubes), maintenance-free

Lower average power consumption

Wider melting range (e.g., stainless steel 0.1–1.0 mm), laser stable without beam wandering

Special chiller ensures long-term high-power welding stability

Objective lens water cooling protects optics during extended use

Deep, firm welds, fully melted, no air holes or sand holes, aesthetically pleasing repair

1.4 Product Models and Technical Parameters

| Parameter | QCW-150W-XB | QCW-300W-XB |

| Maximum laser power | 1500 W | 3000 W |

| Laser type | Fiber laser | Fiber laser |

| Wavelength | 1080 ±5 nm | 1080 ±5 nm |

| Work pattern | QCW | QCW |

| Maximum adjustment frequency | 25 Hz (customizable) | 25 Hz (customizable) |

| Laser welding depth | ≤2.0 mm (depending on material) | ≤3.0 mm (depending on material) |

| Fiber core diameter | 20–200 μm & DOE | 20–200 μm & DOE |

| Fiber length | 6 m (customizable) | 6 m (customizable) |

| Light output mode | QCW | QCW |

| Positioning system | Microscope | Microscope |

| Rated power | 3.3 kW | 4.2 kW |

| Cooling method | Water cooling | Water cooling |

| Power requirement | 220V ±10%, 50Hz / 40A | 220V ±10%, 50Hz / 40A |

| Dimensions (L×W×H) | 1380×1000×1240 mm | 1380×1000×1240 mm |

| Net weight | 295 kg | 295 kg |

1.5 Workplace Requirements

Ambient temperature: 5–35°C (air conditioning recommended)

Humidity: 40–80%, no condensation (dehumidifier recommended)

Power supply fluctuation: <5%; use voltage stabilizer if >5%

Foundation vibration: amplitude <50 μm, acceleration <0.05 g; avoid large stamping machines

Air pressure: 86–106 kPa

Avoid strong electromagnetic interference, radio transmitters nearby

Workspace: smoke-free and dust-free; avoid environments with metal polishing dust

Anti-static measures: optional static shielding, grounded equipment

Cooling water: add antifreeze if ambient <0°C; drain water when machine stops

1.6 Machine Structure and Working Principle

The laser welding machine consists of:

Laser power supply

Optical system

Cooling system

3D worktable

It emits 1080 nm pulsed laser through fiber optics, which is transmitted, expanded, and focused on the workpiece. Microcontroller-controlled pulse frequency and width regulate laser power and energy delivery.

Advantages of QCW fiber laser:

High electro-optical conversion efficiency

Compact structure, maintenance-free

Flexible fiber output for small diameter soldering

Simple wiring and operation via LCD

High-precision QBH fiber; optional 10 m fiber

External communication for monitoring and centralized management

2. Main Components (Chapter 3 Preview)

QCW Fiber Laser

Safety Features: Class IV laser, 1080 nm, OD≥5 protection goggles required

Operation Tips: check cables, connectors, and grounding before powering on

Avoid flammable substances and ensure ventilation