3NM³ Nitrogen Generator (ZHN-03) with Concentration Meter for Laser Cutting and Welding (3-4 Units)

The ZHN-03 Nitrogen Generator offers a robust solution for laser cutting and welding applications. With a controllable flow rate of 3NM³/h and an integrated concentration meter, it ensures precise nitrogen delivery to meet the high standards of industrial production. Deploying 3-4 units provides scalability for large-scale operations, redundancy, and increased nitrogen supply capacity.

Product Specifications

| Parameter | Details |

| Model | ZHN-03 |

| Nitrogen Flow Rate | 3 NM³/h (Controllable) |

| Nitrogen Purity | 99.99% |

| Inlet Air Pressure | 0.6–0.8 MPA |

| Nitrogen Output Pressure | ≤0.6 MPA |

| Power Consumption | 25 W |

| Supply Voltage | AC220V |

| Dimensions (L×W×H) | 700 × 650 × 1300 mm |

| Ports | Air Inlet: 16mm air pipe

Nitrogen Outlet: 12mm air pipe |

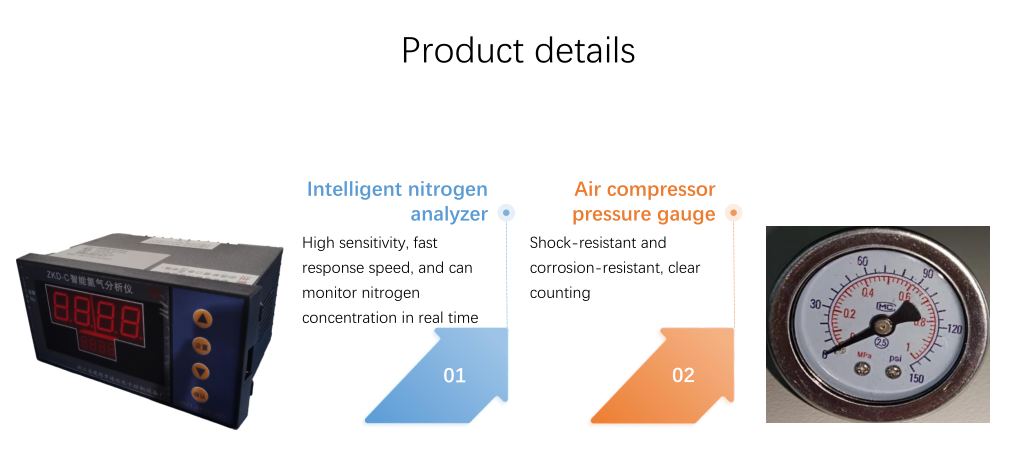

Key Features

High Purity Output (99.99%)

Guarantees contamination-free nitrogen, ensuring clean cuts and high-quality welding results.

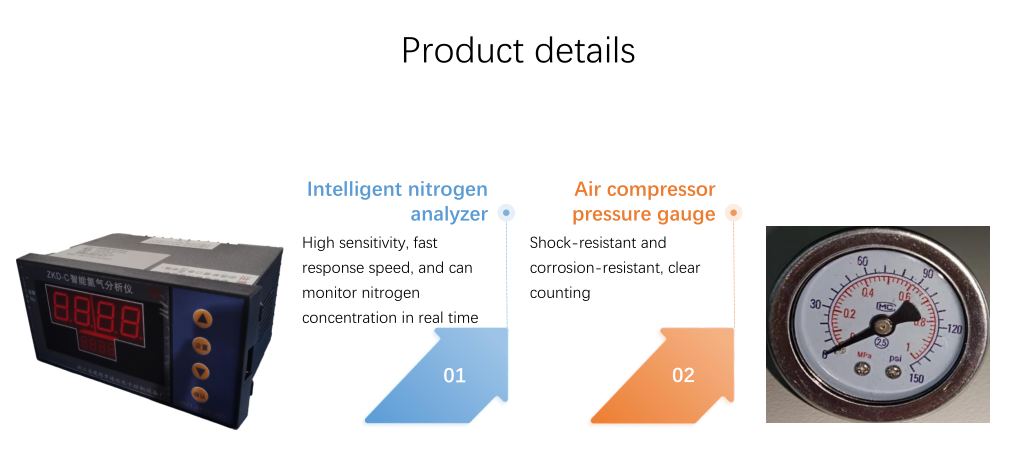

Concentration Meter with Flow Control

The flow meter allows precise control of nitrogen flow.

Reducing flow rate enhances nitrogen purity, ensuring consistency for critical applications.

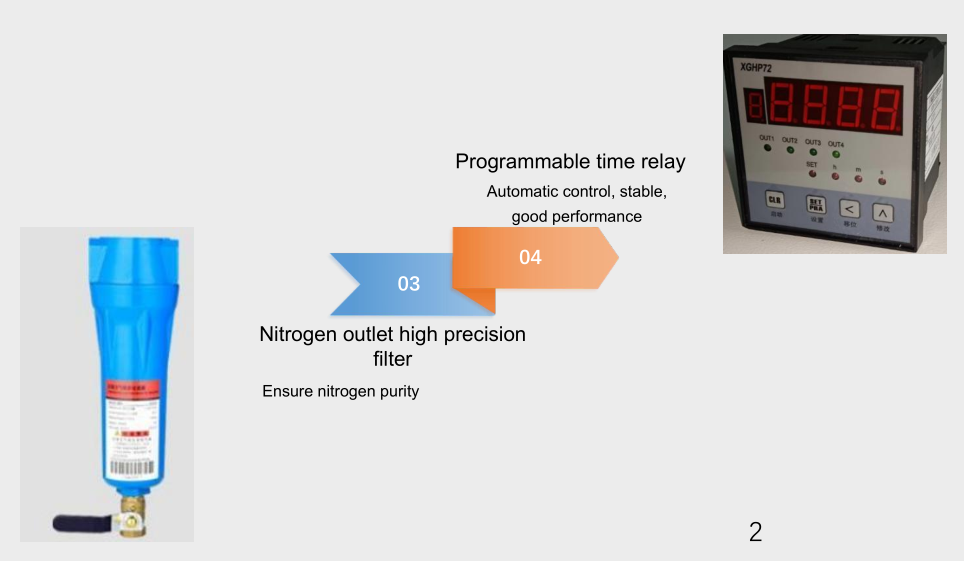

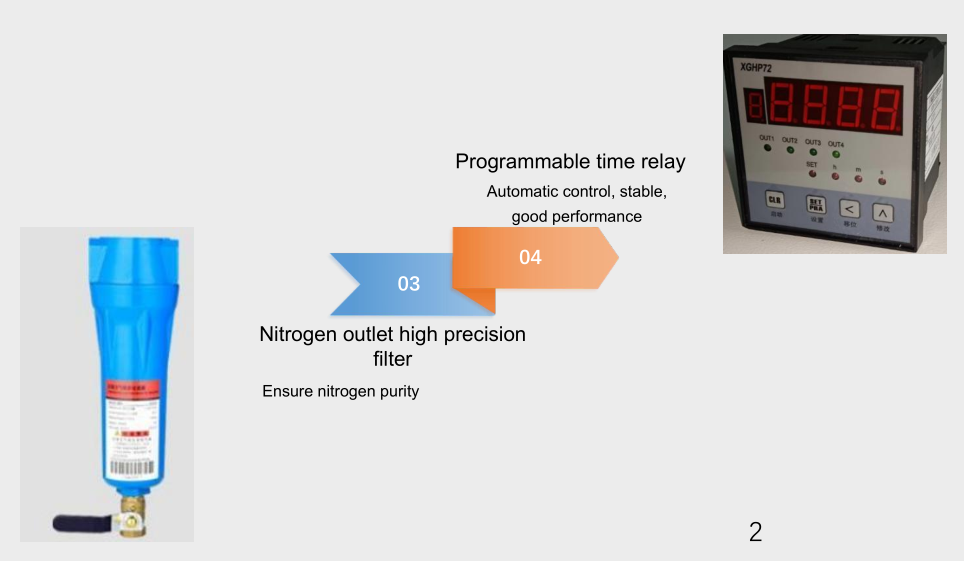

Programmable Time Relay

Controls the working sequence and pressure relief timing for Tower A and Tower B.

Pre-configured for optimal performance, requiring minimal user adjustment.

PSA Technology for Stability

Uses Pressure Swing Adsorption (PSA) technology to separate nitrogen efficiently, maintaining steady output.

Monitoring Features

Air Pressure Gauge: Real-time monitoring of inlet pressure (0.6–0.8 MPA).

Nitrogen Pressure Gauge: Tracks nitrogen pressure in the storage tank.

Tower A and Tower B Pressure Gauges: Displays the operational status of carbon molecular sieve tanks, alternating between active and pressure-relief modes.

Compact and Modular Design

Designed for easy integration into industrial setups. Multiple units (3-4) can operate together to meet higher nitrogen demands.

Advantages of Using 3-4 Units

Enhanced Nitrogen Supply

Provides a combined flow rate of 9-12 NM³/h, suitable for large-scale laser cutting and welding projects.

Redundancy for Continuous Operation

If one unit undergoes maintenance, others can maintain the nitrogen supply.

Scalability

Easily expandable to meet increasing production requirements.

Precise Nitrogen Purity Control

Flow meter adjustments ensure nitrogen purity meets specific process requirements.

Applications

| Industry | Use Case |

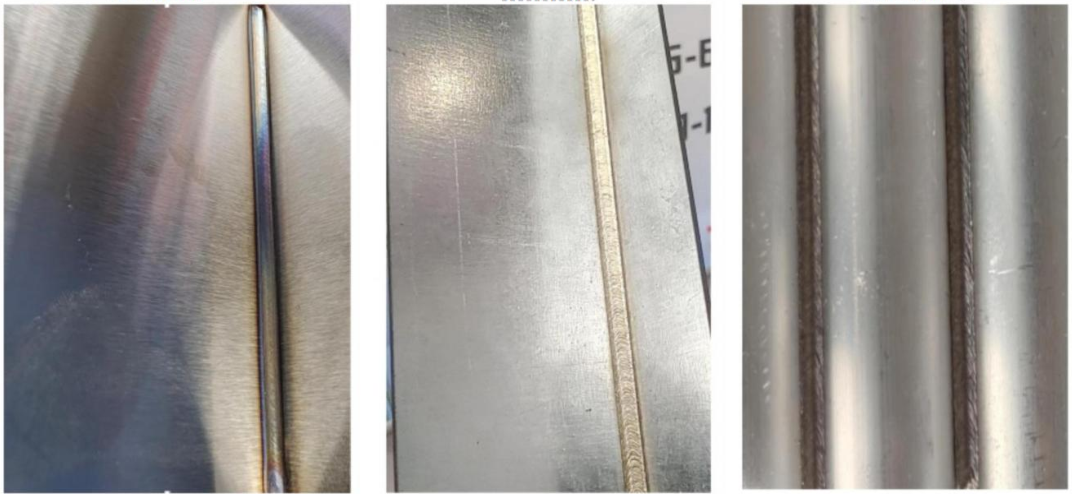

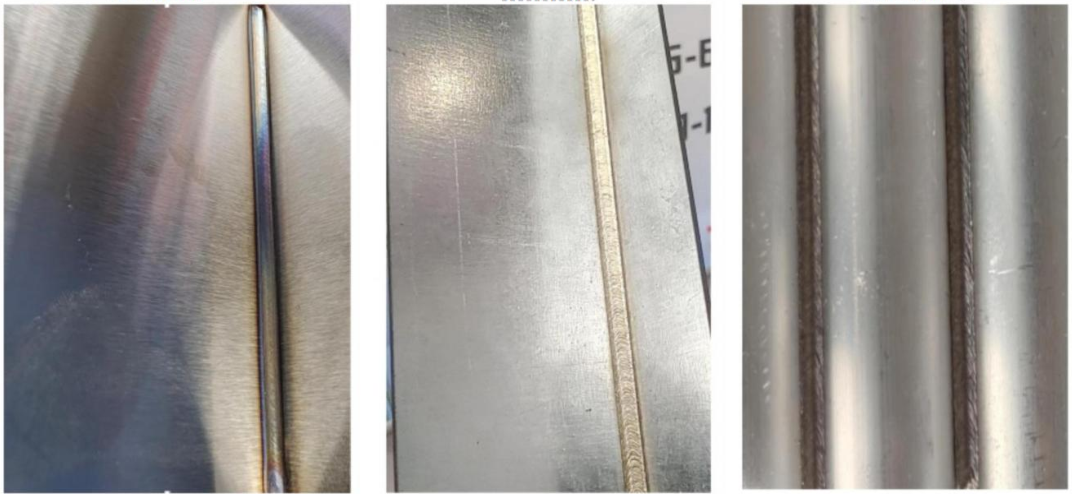

| Laser Cutting | Prevents oxidation for smooth, precise cutting of metals. |

| Welding | Provides an inert environment for cleaner, stronger welds. |

| Electronics | Ensures a contamination-free atmosphere for manufacturing components. |

| Pharmaceuticals | Maintains sterility during production processes. |

| Food Packaging | Increases product shelf life through nitrogen flushing. |

Installation and Maintenance

Air Inlet Preparation

Nitrogen Outlet Connection

Panel Monitoring

Regularly check pressure gauges for the air inlet, nitrogen tank, and towers.

Use the flow meter to adjust the nitrogen flow rate and concentration.

Maintenance Tips