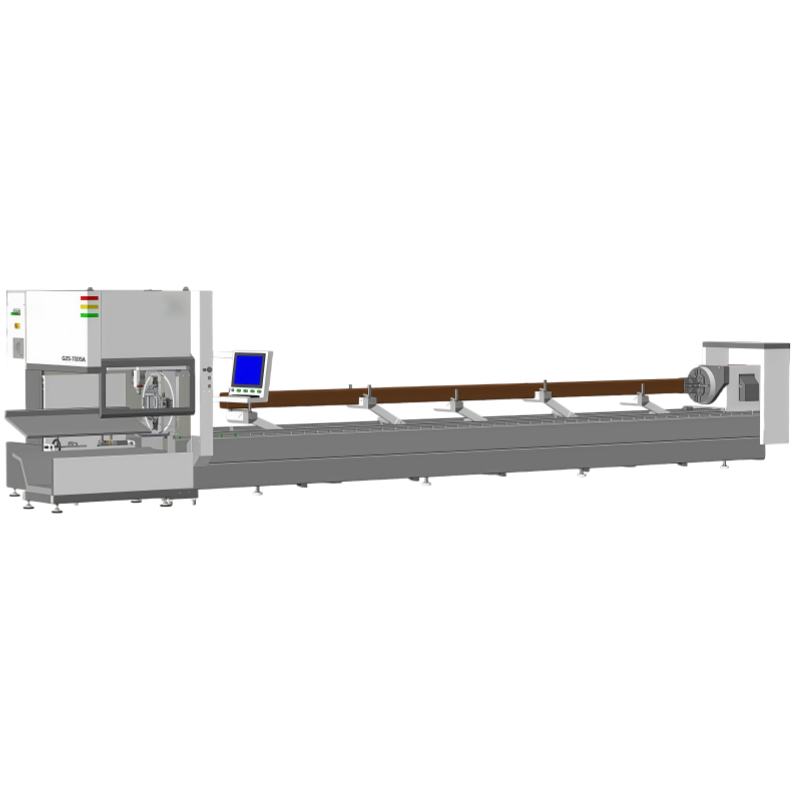

| Device Series | Platform Type | Medium Platform: 250 Series |

| Dimensions (mm) | Length x Width x Height | 9600 x 3200 x 2800 |

| Total Weight (T) | Weight | 6.5T |

| Full Power Consumption (KW) | Consumption | 35-45KW |

| Operating Temperature (°C) | Temperature Range | 0-40°C |

| Processing Range | Pipe Sizes | Round: Ø12-248, Square: 12-175, Rectangular Max: 200 x 120 |

| Cutting Gap Width | 0.1-0.2mm |

| Axis Travel | X/Y/Z/U Axis | 7000/300/450/Unlimited Rotation |

| Positioning Accuracy | X/Y Axis | ±0.03mm per 1000mm |

| U Axis Rotation Accuracy | ≤5 arc-min |

| Max Speed | X/Y Axis Max Speed | 100m/min (X), 120m/min (Y) |

| Feeding System | Automatic Feed Length | 5750-6200mm |

| Manual Feed Length | ≤7000mm |

| Feed Cycle Time | First Feed ≤60s, Subsequent ≤20s |

| Maximum Loading | Automatic Feed Loading Capacity | 1000kg (5 pipes) |

| Manual Feed Single Pipe Max Load | 200kg |

| Automatic Feed Single Pipe Max Load | 180kg |

| Discharge Parameters | Maximum Discharge Length | Standard 2000mm (Optional 4000mm) |

| Tailings Length | ≤45mm |