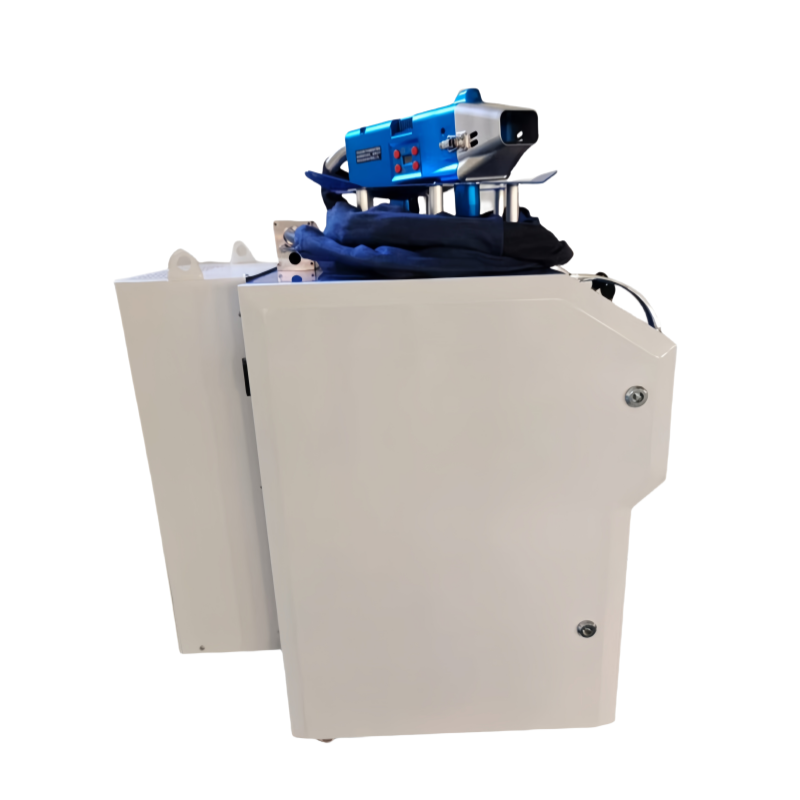

300W Handheld Laser Cleaning Machine

1. Basic Operating Environment

| Content | Parameter |

|---|

| Power Supply Voltage | Single-phase 220V ±10%, 50/60Hz AC |

| Total Power Consumption | < 2500W |

| Placement Environment | Flat, vibration-free, no impact |

| Operating Temperature | 0°C to 40°C |

| Operating Humidity | ≤ 80% |

2. Optical Parameters

| Content | Parameter |

|---|

| Laser Average Power | 300W |

| Power Instability | < 3% |

| Power Adjustment Range | 0-100% (gradually adjustable) |

| Focusing Spot Diameter | 0.1mm |

| Center Wavelength | 1064nm |

| Modulation Frequency | 67KHz-4000KHz (gradually adjustable) |

| Fiber Length | 10M |

| Cleaning Mode | 8 modes, freely switchable |

| Cooling Method | Air cooling |

| Operating Temperature | 5°C to 40°C |

300W Laser Cleaning Machine is a highly effective tool for cleaning a variety of surfaces, offering precision and efficiency.

Functions:

Rust Removal: The 300W laser cleaning machine is highly efficient at removing rust from metal surfaces, ensuring that the original material remains undamaged.

Paint Removal: It can effectively remove coatings, old paint, and varnish without harming the underlying surface, providing a clean and smooth finish.

Oxide Layer Removal: The machine efficiently removes oxide films from metal surfaces, improving their appearance and preparation for further processes such as coating, welding, or painting.

Oil and Contaminant Cleaning: It can clean surfaces contaminated with oils, grease, or other pollutants.

Surface Preparation: It prepares various surfaces by removing unwanted material, making them ready for subsequent manufacturing processes such as bonding, coating, or welding.

Applications:

Metal Surface Cleaning: Perfect for removing rust, paint, and contaminants from various metal surfaces including stainless steel, aluminum, and other alloys.

Automotive Industry: Widely used in the automotive industry to clean metal parts, removing rust and coatings without damaging delicate components.

Shipbuilding and Offshore: Ideal for cleaning the surfaces of ship hulls, offshore equipment, and other large metallic structures.

Aerospace: Used to clean delicate aerospace parts, ensuring precision and removing contaminants or coatings from components like engine parts, turbine blades, and more.

Manufacturing and Maintenance: Widely used in general manufacturing, maintenance, and repair industries to clean parts, tools, and machinery.

Mold Cleaning: Effectively cleans molds by removing contaminants, oxidation, and dirt, ensuring they are ready for further production.

Electrical and Electronics: Used to remove oxide layers and other contaminants from metal parts used in electronics and electrical equipment, enhancing conductivity and ensuring a clean surface for connections.

Cultural Heritage Preservation: The machine is also suitable for cleaning and restoring metal surfaces of sculptures, historical artifacts, and cultural heritage objects without causing damage.

Operation:

User-Friendly Interface: Features an easy-to-use interface, making it accessible for a wide range of users from novice to advanced operators.

Portable and Flexible: This machine is designed for portability, enabling use in various environments, including on-site cleaning.

Adjustable Power: The 300W laser power is adjustable, allowing users to select the appropriate level of power for different surfaces and contamination types.

Efficient Cooling System: Equipped with a built-in air-cooling system to maintain stable performance and prevent overheating during extended use.

Various Cleaning Modes: The machine supports multiple cleaning modes, enabling users to choose the best setting based on the type of material and contaminants.

Low Maintenance: With minimal wear parts, the machine is low-maintenance and easy to operate, resulting in reduced downtime and cost of ownership.

Environmental Friendly: The laser cleaning process produces no chemicals, reduces waste, and is environmentally friendly compared to traditional cleaning methods.

The 300W Laser Cleaning Machine is highly effective, versatile, and ideal for industries requiring high precision, fast cleaning, and maintenance of various metal surfaces. It is suitable for heavy-duty applications in industrial, automotive, aerospace, and manufacturing sectors.