400mm Wet Wide Belt Sander and Polishing Machine for Deburring, Polishing, and Surface Finishing of Laser-Cut and Stamped Sheet Metal (Model: RP5240)

The RP5240 400mm Wet Wide Belt Sander and Polishing Machine is a versatile industrial-grade solution for deburring, polishing, and surface finishing of laser-cut and stamped sheet metal parts. This machine features a single wide belt sanding station combined with a Nylon Fiber Wheel Flap Polishing Wheel to deliver high-precision material processing in a single pass.

Designed for stainless steel, aluminum, carbon steel, and other metal materials, the RP5240 effectively removes burrs, smooths sharp edges, polishes surfaces, and enhances the overall finish. Utilizing a wet grinding and polishing process, it ensures minimal heat generation, dust suppression, and consistent surface quality, making it ideal for automotive, aerospace, electronics, kitchenware, and general metal fabrication industries.

With a maximum working width of 400mm, this machine is particularly suited for medium-sized metal sheets and components, offering high efficiency, consistent finishing, and improved workplace safety.

Key Features & Functions

1. Dual-Process System: Sanding and Polishing

First Station: Wide Belt Sanding (7.5kW)

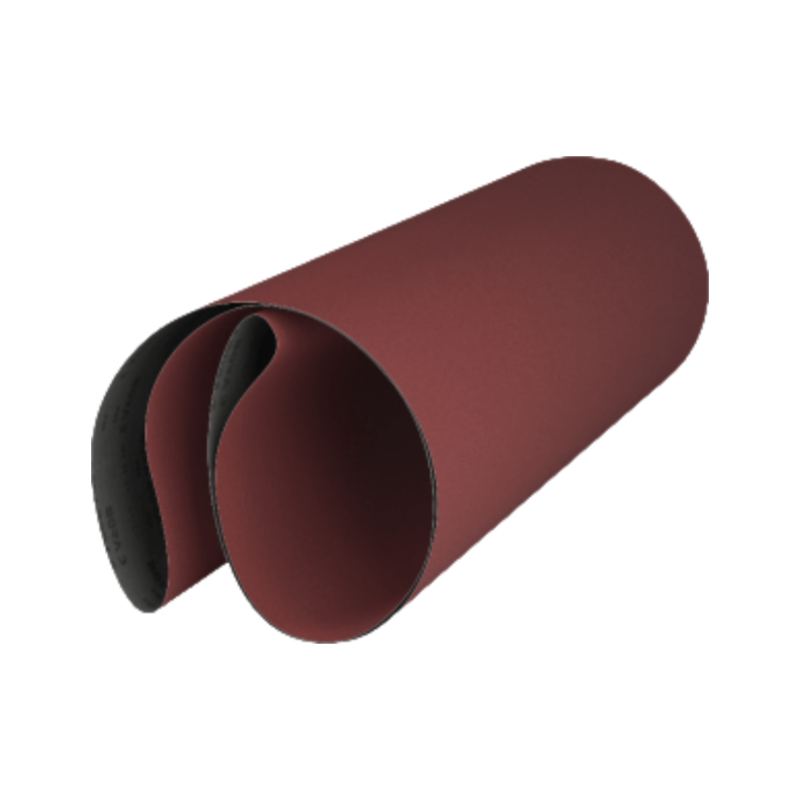

Equipped with a 1520×400mm abrasive belt to deburr and smooth rough edges.

Removes oxide layers, surface scratches, and imperfections from laser-cut or stamped metal parts.

Prepares surfaces for further finishing, coating, or welding.

Second Station: Nylon Fiber Wheel Flap Polishing Wheel

Delivers precision polishing to achieve a refined, satin-like surface finish.

Ensures uniformity across metal surfaces, reducing inconsistencies and improving final product appearance.

Suitable for decorative finishing, mirror polishing, or preparing surfaces for coating and anodizing.

2. Wet Sanding & Polishing for Superior Quality

Water-based grinding and polishing technology cools the workpiece, preventing heat deformation and discoloration.

The wet system minimizes airborne dust and metal particles, improving workplace safety and cleanliness.

A circulating coolant system increases abrasive belt and polishing wheel lifespan, ensuring consistent performance.

3. Wide Compatibility for Various Metal Parts

Capable of processing materials up to 400mm wide and 60mm thick, making it ideal for laser-cut, stamped, and punched metal sheets.

The minimum workpiece length of 150mm allows for small to medium-sized component processing.

Compatible with stainless steel, aluminum, carbon steel, copper, and other non-ferrous metals.

4. Precision Feeding & Adjustable Controls

High-precision conveyor feed system ensures smooth material transport for consistent finishing.

Adjustable feed speed enables customization based on material type and processing requirements.

User-friendly control panel for easy adjustment of sanding pressure, speed, and polishing settings.

5. Compact & Heavy-Duty Design

The machine has a rugged industrial frame for stability and durability in high-production environments.

Compact footprint (2.1m × 1.5m × 1.8m) allows for easy integration into existing production lines.

Stainless steel construction ensures corrosion resistance in wet sanding applications.

6. Energy-Efficient & Low Maintenance

Independent motor drives optimize energy consumption for both sanding and polishing stations.

Quick-change abrasive belt and polishing wheel system minimizes downtime and improves production efficiency.

Automatic water filtration and drainage system for reduced maintenance and enhanced performance.

Technical Specifications

| Parameter | Unit | RP5240 Model |

|---|---|---|

| Max. Working Width | mm | 400 |

| Max. Working Height | mm | 60 |

| Min. Working Length | mm | 150 |

| First Sanding Belt Power | kW | 7.5 |

| Second Sanding Belt Power | kW | / |

| Third Sanding Belt Power | kW | / |

| Polishing Wheel Power | kW | / |

| Rotation Motor Power | kW | / |

| Feeding Motor Power | kW | 1.5 |

| Lifting Motor Power | kW | 0.37 |

| Oscillation Motor Power | kW | 1.5 |

| Vacuum Motor Power | kW | / |

| Machine Dimensions (L×W×H) | m | 2.1 × 1.5 × 1.8 |

| Machine Weight | kg | 1200 |

| Sanding Belt Size | mm | 1520 × 400 |

Typical Applications

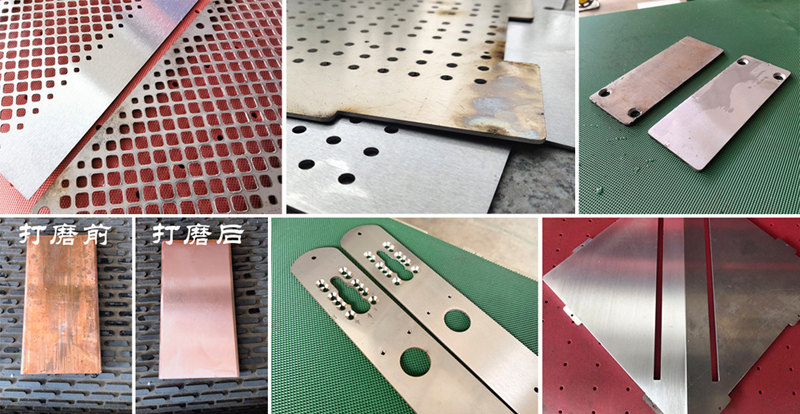

1. Deburring and Edge Smoothing for Laser-Cut and Stamped Parts

Removes sharp edges and burrs from laser-cut, punched, or stamped sheet metal.

Ensures safer handling and assembly with smooth, rounded edges.

Prepares parts for coating, welding, and other finishing processes.

2. Surface Polishing for Stainless Steel and Aluminum

Achieves a uniform brushed or satin finish for decorative metal parts.

Enhances surface appearance, durability, and corrosion resistance.

Ideal for applications in kitchenware, electronics, architecture, and automotive parts.

3. Oxide Layer Removal & Pre-Coating Preparation

Effectively eliminates oxidation layers from laser-cut and plasma-cut metal parts.

Improves adhesion for coatings, paint, powder coating, and anodizing.

Ensures consistent surface preparation, reducing defects in downstream processes.

4. Brushed Finishing for Industrial & Consumer Metal Products

Provides fine surface texturing for improved grip and aesthetic quality.

Commonly used in automotive trim, home appliances, industrial machinery panels, and consumer electronics.

Conclusion

The RP5240 400mm Wet Wide Belt Sander and Polishing Machine is a high-efficiency solution for deburring, polishing, and surface finishing of laser-cut and stamped sheet metal. Its combination of a sanding belt and Nylon Fiber Wheel Flap Polishing Wheel allows for precision metal processing with minimal material waste and maximum quality.

By integrating the RP5240 model into your production line, you can achieve:

✅ Superior surface quality with consistent deburring and polishing

✅ Efficient removal of burrs, oxidation layers, and surface scratches

✅ Increased productivity with automated finishing processes

✅ Cost savings on manual labor and consumables

This machine is an ideal choice for manufacturers in automotive, aerospace, electronics, kitchenware, industrial equipment, and precision metalworking industries looking to enhance product quality and production efficiency.