WBL-40/1500 CNC Double Servo Hybrid Press Brake

The WBL-40/1500 CNC Double Servo Hybrid Press Brake is a cutting-edge sheet metal bending machine that combines servo-electric and hydraulic technologies to offer a highly efficient, precise, and environmentally friendly solution for bending metal plates. With its dual servo motors and hybrid system, this press brake is designed to deliver exceptional power, flexibility, and energy savings while ensuring superior bending accuracy. Ideal for a wide range of industries, the WBL-40/1500 is perfect for high-precision bending operations in automotive, aerospace, construction, and manufacturing.

Double Servo Electro-Hydraulic Hybrid Press Brake parameters:

| Parameter Name | Unit | WBL-40/1500 | WBL-100/2500 | WBL-100/3200 | WBL-100/4100 | WBL-160/3200 | WBL-160/4100 | WBL-200/3200 | WBL-200/4100 |

| Bending Force | kN | 400 | 1000 | 1000 | 1000 | 1600 | 1600 | 2000 | 2000 |

| Effective Bending Length | mm | 1500 | 2500 | 3200 | 4100 | 3200 | 4100 | 3200 | 4100 |

| Maximum Opening Height | mm | 400 | 460 | 460 | 460 | 460 | 460 | 500 | 500 |

| Column Distance | mm | 1140 | 2010 | 2700 | 3600 | 2700 | 3600 | 2700 | 3600 |

| Throat Depth | mm | 300 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Ram Stroke | mm | 160 | 200 | 200 | 200 | 200 | 200 | 240 | 240 |

| Fast Down Speed | mm/s | 240 | 240 | 240 | 240 | 200 | 200 | 200 | 200 |

| Working Speed | mm/s | 10-15 | 10-15 | 10-15 | 10-15 | 10-14 | 10-14 | 10-14 | 10-14 |

| Return Speed | mm/s | 220 | 220 | 220 | 220 | 200 | 200 | 200 | 200 |

| Motor Power | kW | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 | 7.5*2 | 7.5*2 | 7.5*2 | 7.5*2 |

| Oil Tank Capacity | L | 40*2 | 40*2 | 40*2 | 40*2 | 65*2 | 65*2 | 65*2 | 65*2 |

| Overall Dimensions | Length (mm) | 1700 | 2700 | 3400 | 4300 | 3500 | 4300 | 3500 | 4300 |

| Width (mm) | 1540 | 1600 | 1600 | 1600 | 1650 | 1650 | 1900 | 1900 |

| Height (mm) | 2350 | 2400 | 2500 | 2550 | 2630 | 2630 | 2750 | 2750 |

| Machine Weight | kg | 3800 | 7500 | 9800 | 11500 | 11800 | 13800 | 14700 | 16000 |

Key Features and Functions

1. CNC Control System

The WBL-40/1500 comes with a CNC (Computer Numerical Control) system that provides precise and automated control over the bending process. The intuitive touch-screen interface allows operators to program and monitor the machine easily. CNC control ensures consistent bending quality with high repeatability, making it perfect for both small batches and large-scale production runs.

Automatic Bending Programs: The machine supports the creation of custom bending programs for different sheet metal components, ensuring quick transitions between production runs.

Easy-to-Use Interface: The CNC control interface is user-friendly, offering easy navigation through complex bending processes and reducing the learning curve for operators.

Real-Time Monitoring: Operators can monitor the bending operation in real-time, making adjustments as needed for better accuracy and efficiency.

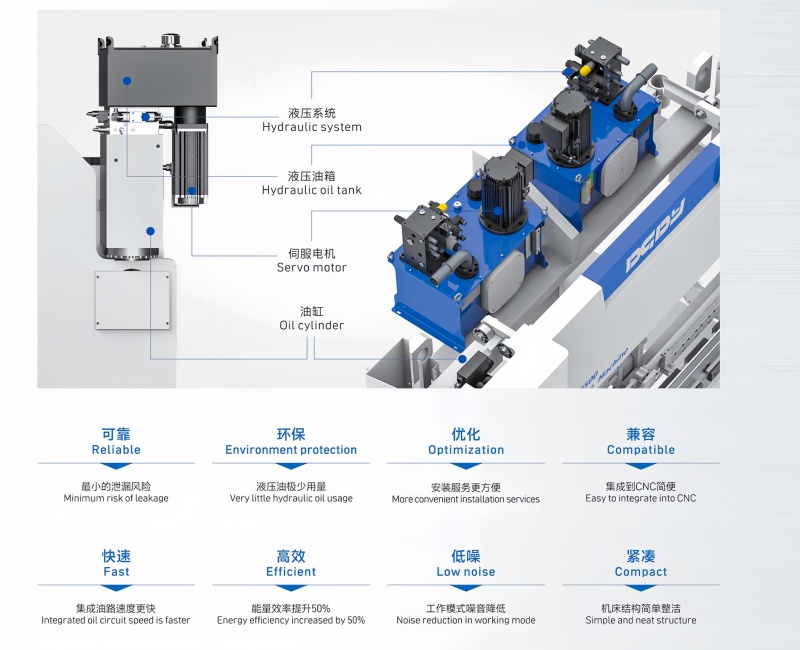

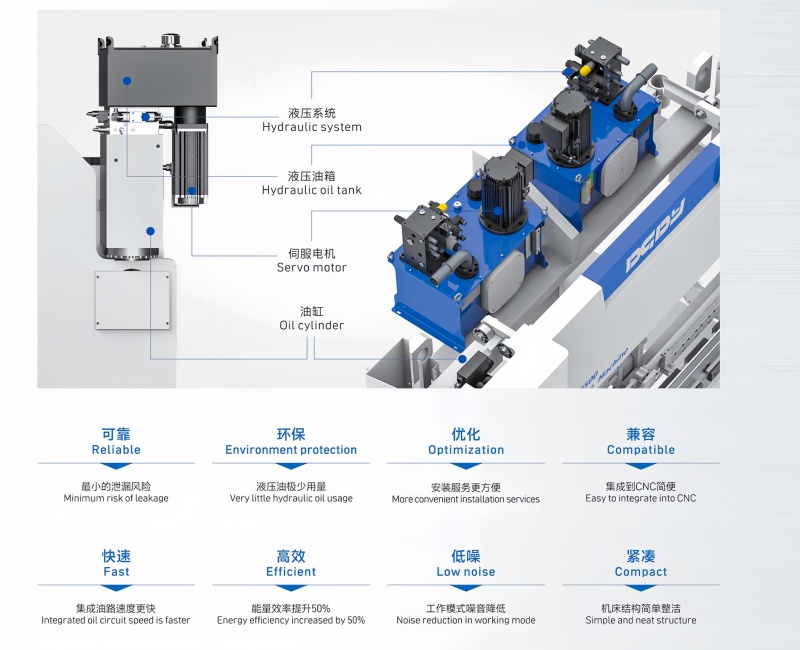

2. Double Servo Hybrid Drive

The servo-electric hybrid drive system used in the WBL-40/1500 combines the benefits of electric servo motors with hydraulic technology. This unique system offers several advantages:

Energy Efficiency: The servo motors consume power only when required, resulting in energy savings of up to 50% compared to traditional hydraulic press brakes.

Reduced Maintenance: The hybrid drive eliminates the need for complex hydraulic systems and fluids, significantly reducing maintenance requirements and operating costs.

Enhanced Precision: The servo system provides smooth, precise control over the bending process, allowing for high repeatability and tight tolerances in the bends.

Environmentally Friendly: The absence of hydraulic oil reduces environmental concerns and makes the machine more eco-friendly.

3. Bending Force and Length

Bending Force: The WBL-40/1500 delivers a bending force of 400 kN, ensuring sufficient power for forming thicker and harder materials without compromising precision.

Effective Bending Length: The machine is designed to handle sheet metal with an effective bending length of 1500 mm, making it suitable for a wide range of industrial applications, from smaller parts to medium-sized sheet metal components.

4. Maximum Opening Height and Ram Stroke

Maximum Opening Height: The machine can accommodate a maximum opening height of 400 mm, which provides ample space for various workpieces and tool configurations.

Ram Stroke: The ram stroke is 160 mm, allowing for precise material handling and optimal bend formation for different thicknesses and sizes of sheet metal.

5. Fast Down and Return Speeds

Fast Down Speed: The WBL-40/1500 achieves a fast downward movement speed of 240 mm/s, allowing for rapid approach to the workpiece, reducing cycle times.

Return Speed: The machine has a return speed of 220 mm/s, ensuring efficient return to the starting position for subsequent operations.

6. Precise Backgauge System

The CNC-controlled backgauge system allows for precise positioning of the workpiece, ensuring accurate and repeatable bends. The backgauge is adjustable, providing flexibility to accommodate different sheet sizes and bending requirements.

Automated Adjustments: The backgauge adjusts automatically based on the programmed parameters, ensuring consistent accuracy throughout the bending process.

High-Speed Operation: The backgauge operates quickly and with precision, minimizing the time required for adjustments and increasing overall throughput.

7. Safety and Operator Comfort

The WBL-40/1500 is designed with safety features that ensure operator protection during operation. These include:

Safety Shields and Emergency Stops: To protect operators from potential hazards, the machine includes safety shields and emergency stop buttons.

Low Noise Operation: The hybrid drive system operates with minimal noise, creating a more comfortable work environment.

Ergonomically Designed Controls: The control system is positioned for easy access, reducing operator fatigue and improving overall productivity.

Applications and Uses

The WBL-40/1500 CNC Double Servo Hybrid Press Brake is versatile and can be used in various industries for high-precision sheet metal bending operations. Its flexible design and advanced features make it suitable for both small-scale and large-scale production, handling a wide range of materials, including steel, stainless steel, aluminum, and copper.

1. Automotive Industry

Bending of body panels, chassis parts, and other components used in vehicle manufacturing.

High precision bending for complex shapes and parts that require tight tolerances.

2. Aerospace Industry

Manufacturing of lightweight and high-strength components for aircraft, such as wing structures, fuselage components, and other critical parts.

The press brake's precision and control make it ideal for bending advanced materials used in aerospace engineering.

3. Construction and Heavy Machinery

Bending of structural steel components used in the construction of buildings, bridges, and industrial machinery.

The machine can handle large, heavy components, making it suitable for bending beams, brackets, and other construction parts.

4. Metal Fabrication and Sheet Metal Work

Suitable for custom metal fabrication and production of sheet metal components.

Ideal for the production of parts used in various industries, such as electrical enclosures, panels, and decorative components.

5. Home Appliances and Consumer Goods

Bending sheet metal parts used in the manufacture of consumer appliances like refrigerators, air conditioners, and washing machines.

Precision bending for parts with complex geometries or tight tolerances.

Advantages

Energy Efficiency: The hybrid drive system significantly reduces power consumption, making the WBL-40/1500 a cost-effective solution for long-term operations.

Precision and Accuracy: With CNC control and advanced servo-driven technology, the machine delivers highly accurate bends, ensuring consistency in every operation.

Flexible and Versatile: The machine is capable of handling various sheet thicknesses and sizes, making it suitable for a broad range of applications.

Reduced Downtime: With the automated tool setup and low-maintenance design, the WBL-40/1500 ensures high productivity and reduced downtime.

Eco-Friendly: The all-electric servo drive system and hydraulic hybrid design make this press brake environmentally friendly by eliminating the need for hydraulic oil and reducing overall power consumption.