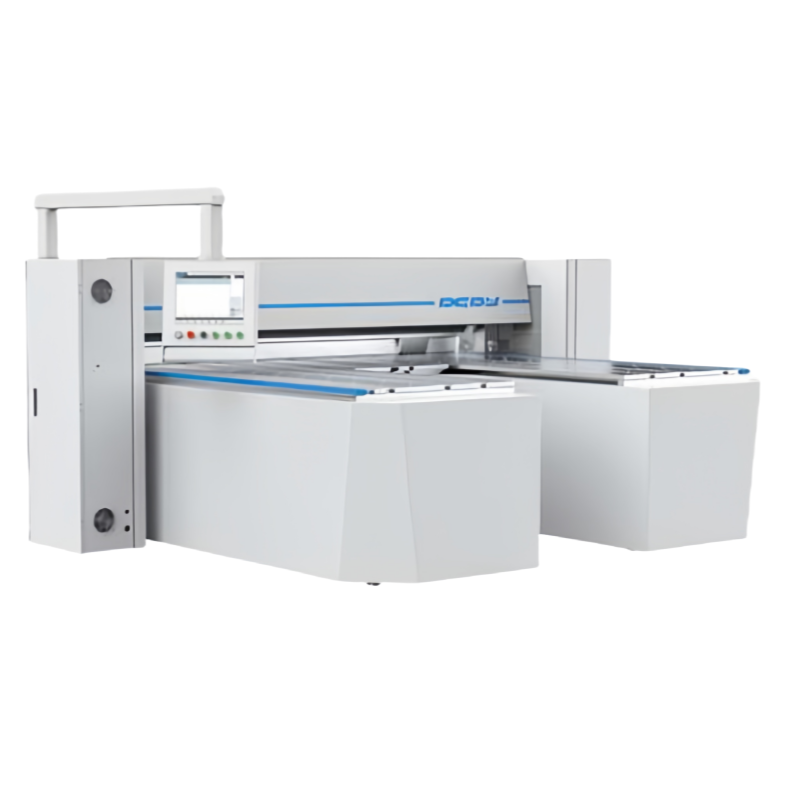

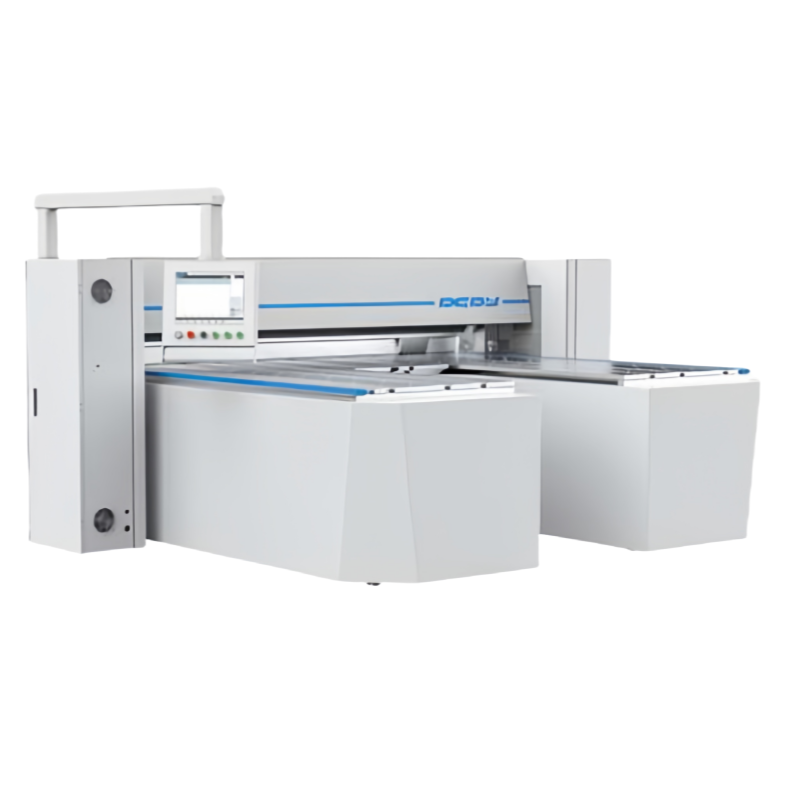

TB041 CNC Sheet Metal Folding Machine

4100mm Sheet Metal Folder for Large-Format Precision Bending

The TB041 CNC Folding Machine is the largest model in the TBO single-side upward folding series, offering a maximum working length of 4100 mm. Designed for handling long and oversized sheet metal panels, it delivers superior folding accuracy, consistent quality, and efficient performance. With advanced CNC control, heavy-duty structure, and energy-efficient design, the TB041 is an ideal solution for manufacturers producing architectural panels, elevator walls, industrial cabinets, and other large-format sheet metal parts.

1. Extended Folding Capacity

With its 4100 mm maximum bending length, the TB041 accommodates oversized sheet metal parts such as façade panels, door frames, and industrial enclosure bodies. It is well-suited for manufacturers working with longer sheets or requiring higher flexibility in part design.

Max. Folding Length: 4100 mm

Max. Carbon Steel Thickness: 2.0 mm

Max. Stainless Steel Thickness: 1.5 mm

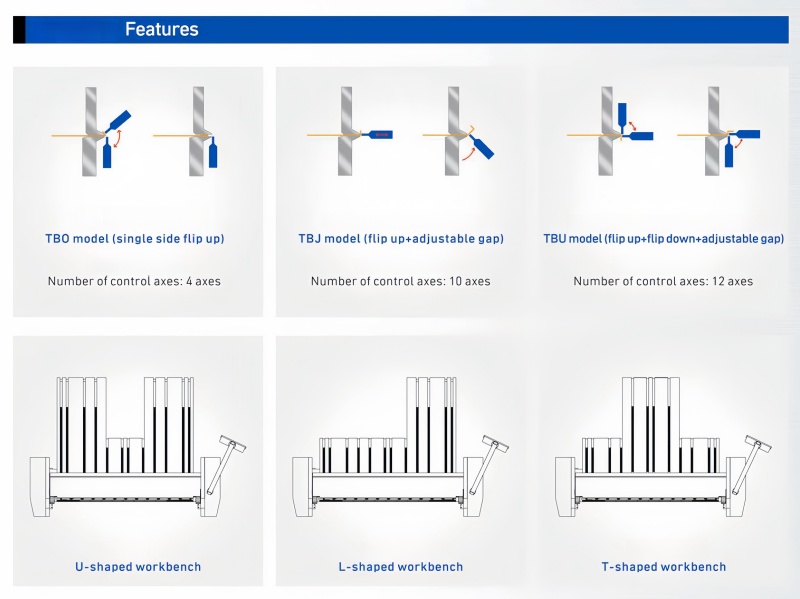

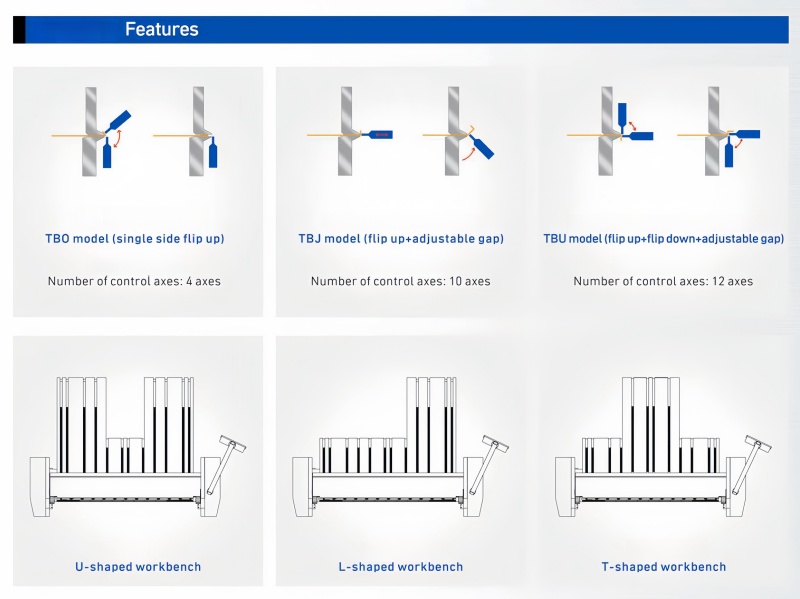

2. CNC-Controlled Accuracy

Equipped with a 4-axis CNC control system, the TB041 ensures accurate programming of folding angles, clamping, and back gauge positioning. Its CNC interface is user-friendly, enabling operators to achieve precise bends with minimal setup time.

3. High-Speed Operation

The TB041 is engineered for efficiency, with a clamping speed of 200 mm/s and a folding speed of 100°/s. This enables fast cycle times, improving throughput in high-volume production environments.

Clamping Speed: 200 mm/s

Folding Speed: 100°/s

4. Robust and Durable Structure

Built with a heavy-duty welded steel frame, the TB041 provides stability and minimizes vibration during long-sheet operations. Its solid construction ensures consistent accuracy, even when processing large and heavy workpieces.

5. Energy-Efficient Drive System

Powered by a 6.5 kW motor, the TB041 combines strength with efficiency, offering the necessary power for large-format folding while keeping energy consumption manageable.

Performance Advantages

Large-Format Capability: Handles sheet lengths up to 4100 mm, ideal for architectural and industrial applications.

Precision Folding: CNC-controlled system guarantees accurate bending angles and repeatable results.

High Productivity: Fast clamping and folding speeds reduce cycle time and improve throughput.

Durability: Heavy-duty construction ensures long service life and stability.

User-Friendly: CNC touchscreen simplifies operation, reducing operator training requirements.

Applications

The TB041 is designed for industries requiring long and large sheet metal folding. Typical applications include:

Construction & Architecture: Façade panels, roofing sheets, long door and window frames.

Elevators & Transportation: Elevator cabin panels, train and bus interior sheet parts.

Electrical Enclosures: Large control cabinets, switchgear housings.

Industrial Equipment: Machine casings, protective covers, industrial workstations.

Stainless Steel Fabrication: Kitchen panels, furniture components, decorative trims.

Technical Specifications (TB041)

| Item | Unit | TB041 |

| Max. Sheet Thickness (Carbon Steel) | mm | 2.0 |

| Max. Sheet Thickness (Stainless Steel) | mm | 1.5 |

| Bending Angle Range | ° | 45–180 |

| Max. Bending Length | mm | 4100 |

| Back Gauge Length | mm | 4100 |

| Open Height | mm | 380 |

| Tool Height | mm | 125 |

| Control Axes | — | 4 |

| Clamping Speed | mm/s | 200 |

| Folding Speed | °/s | 100 |

| Motor Power | kW | 6.5 |

| Machine Dimensions (L × W × H) | mm | 5300 × 5700 × 2150 |

| Machine Weight | Kg | 7500 |

Conclusion

The TB041 CNC Folding Machine is the perfect solution for manufacturers requiring long-format sheet metal folding with high accuracy and efficiency. With its 4100 mm bending length, strong structural design, and advanced CNC control, the TB041 ensures seamless bends and creases across a wide range of applications. For architectural panels, elevator walls, or industrial cabinets, the TB041 delivers the precision and reliability that modern sheet metal fabrication demands.

Example Specifications:

Max Bending Length: 4100mm

Bending Thickness:

Bending Angle Range: 45° to 180°

Axes Control: 4-6 axes

Power Source: Servo-driven motors (Energy efficient)

Control System: CNC with programmable interface

Safety: Light curtain protection, auto shut-off, emergency stop

Weight: Approximately 8,000 to 11,000 kg depending on the specific model

A 4100mm sheet metal folding machine offers robust performance and flexibility for manufacturers who need to handle large sheets with precision, efficiency, and safety. If you're considering purchasing such a machine, make sure to focus on factors such as motor capacity, CNC control features, and the available tooling to meet your specific manufacturing needs.

Technical Parameter

| Item | Unit | TB025 | TB032 | TB041 | TBJ25 | TBJ32 | TBJ41 | TBU25 | TBU32 | TBU41 |

| Bending thickness (carbon steel) | mm | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Bending thickness (stainless steel) | mm | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Bending angle range | degrees | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | -45...+45 | -45...+45 | -45...+45 |

| Max. bending length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Rear positioning length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Open height | mm | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Bending tool height | mm | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 |

| Control axis number |

| 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Pressing speed | mm/s | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Bending speed | m/s | 5.0 | 5.0 | 5.0 | 6.5 | 6.5 | 6.5 | 7.0 | 7.0 | 7.0 |

| Motor energy consumption | kW | 3.5 | 4.5 | 6.1 | 3.5 | 4.5 | 6.1 | 5.5 | 7.0 | 10.0 |

| External dimensions (L × W × H) | mm | 3100×1650 | 3800×1950 | 5300×2150 | 3100×1650 | 3800×1950 | 5300×2150 | 3100×1650 | 3800×1950 | 5700×2150 |

| Weight | kg | 4500 | 5300 | 7500 | 4500 | 5300 | 7500 | 4900 | 7000 | 11000 |

This table provides information on various models of CNC sheet metal folding machines, highlighting their specifications such as bending thickness, bending angle range, maximum bending length, open height, speed, motor energy consumption, dimensions, and weight.