ZHN-03 Industrial Nitrogen Generator for Laser Welding Applications

(Compatible with handheld & benchtop laser welding systems)

Nitrogen Generation Machines for Laser Welding Applications

1. Core Product Keywords

Nitrogen generator for laser welding

Industrial nitrogen generator

PSA nitrogen generator (Pressure Swing Adsorption)

High-purity nitrogen generator (95%~99.999%)

On-site nitrogen gas system

Laser welding nitrogen supply

2. Technical & Performance Keywords

Nitrogen flow rate (Nm³/min)

Nitrogen purity for laser welding (99.9% vs. 99.999%)

Oxygen-free welding gas system

Nitrogen pressure regulator for welding (0.5-0.8 MPa)

Continuous nitrogen supply for laser machines

Low dew point nitrogen generation

3. Application-Specific Keywords

Nitrogen generator for handheld laser welding

Nitrogen for fiber laser cutting/welding

Stainless steel welding nitrogen protection

Aluminum welding anti-oxidation gas

Laser metal fabrication gas solutions

4. Cost & Efficiency Keywords

Replace nitrogen cylinders with generator

Cost-saving nitrogen generation

Energy-efficient nitrogen production

Low-maintenance nitrogen systems

ROI of on-site nitrogen generation

5. Comparative & Commercial Keywords

Nitrogen generator vs. gas cylinders

Best nitrogen generator for small workshops

Industrial vs. portable nitrogen machines

How to choose a nitrogen generator for welding

Top-rated nitrogen gas systems for lasers

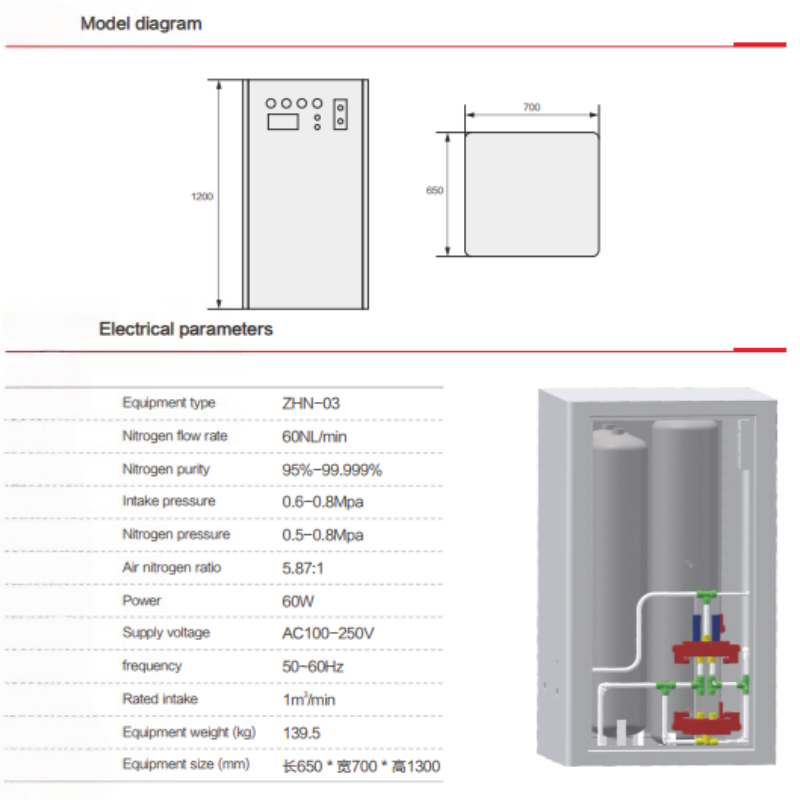

Technical Specifications

| Parameter | Specification |

| Model | ZHN-03 |

| Nitrogen Flow Rate | 60 Nm³/min |

| Nitrogen Purity | 95%~99.999% (adjustable) |

| Operating Pressure | 0.6~0.8 MPa (intake)

0.5~0.8 MPa (output) |

| Air/Nitrogen Ratio | 5.87:1 |

| Power Consumption | 60W |

| Electrical Requirements | AC 100-250V, 50/60Hz |

| Air Intake | 31 m³/min |

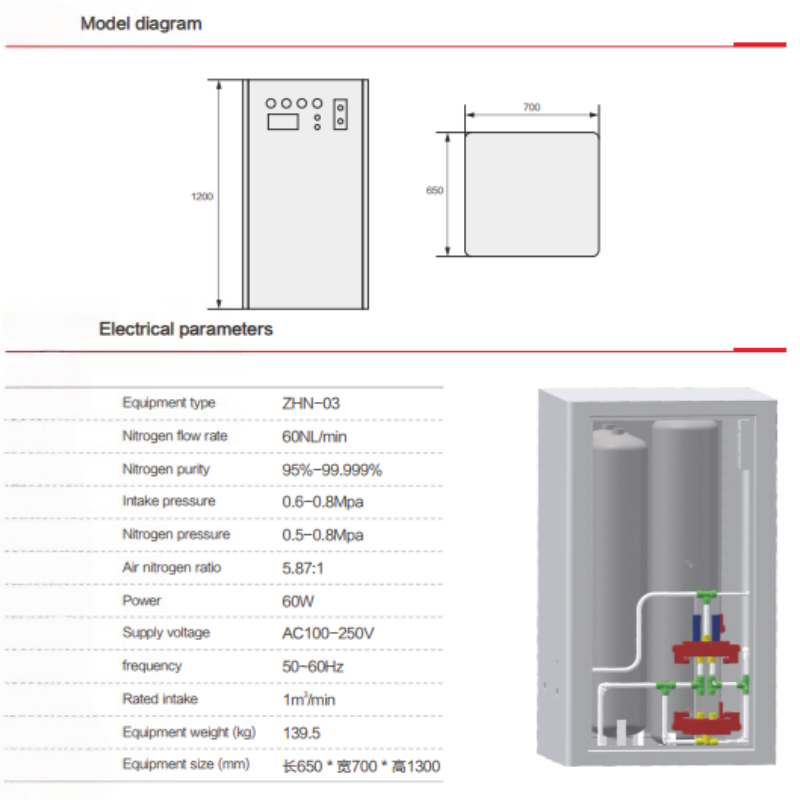

| Dimensions (L×W×H) | 650 × 700 × 1300 mm |

| Weight | 139.5 kg |

Key Features

High-Capacity Output: 60 Nm³/min flow rate supports multiple laser welding stations

Precision Gas Control: 95-99.999% purity range prevents weld oxidation

Industrial-Grade Design: Heavy-duty construction (139.5kg) for continuous operation

Energy Efficient: Optimized PSA technology with only 60W power draw

Universal Compatibility: Works with both handheld and platform laser welding systems

Performance Benefits

Eliminates porosity in stainless steel, aluminum, and titanium welds

Consistent nitrogen delivery improves weld seam quality

Reduces dependency on gas cylinders

System Diagram

(Refer to engineering schematics for component layout and connections)

Welding Results