MSD-C650 Finishing Machine

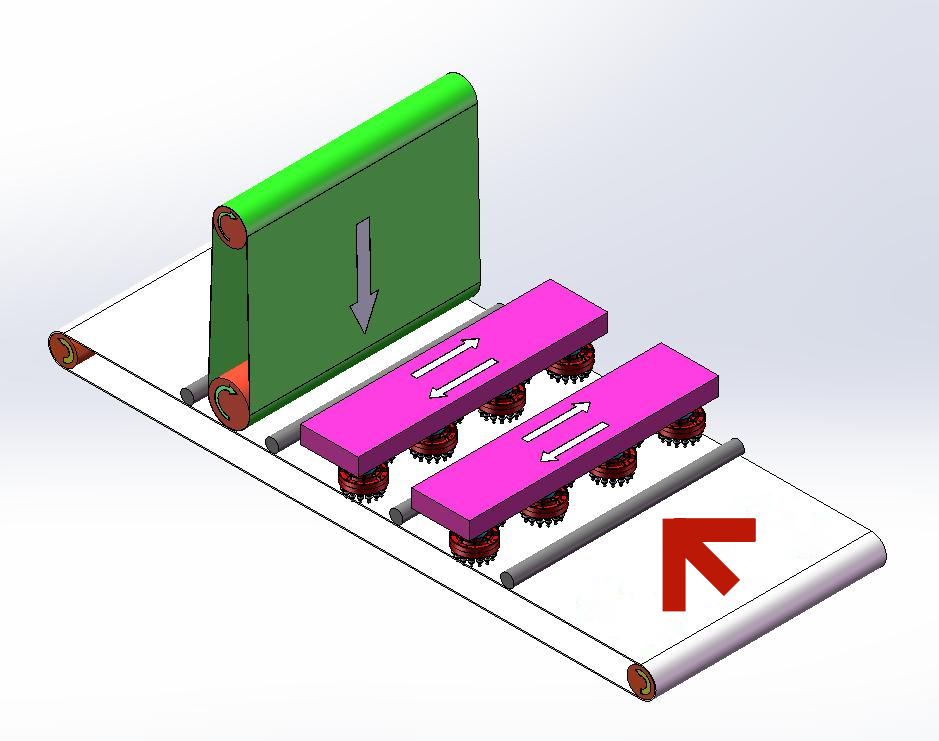

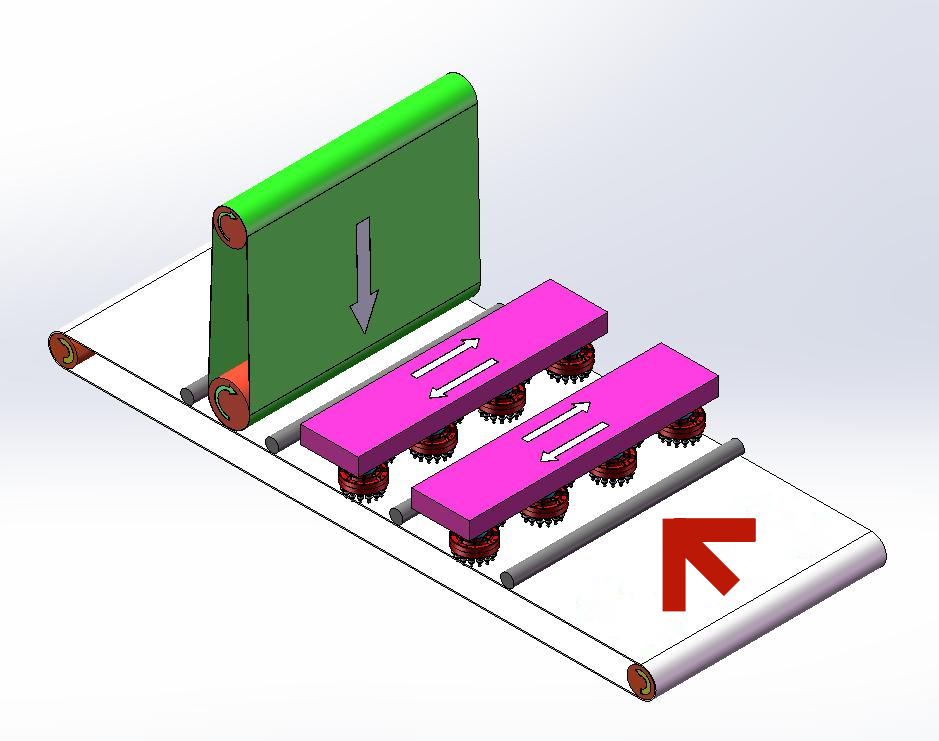

650mm Metal Deburring Machine for Super-fast Deburring Edge Rounding And Finishing of Small Sheet Metal Parts The C600, a 3-station finishing machine, guarantees a safe and efficient processing of even the smallest parts thanks to the standard magnet or vacuum system. The grinding unit is automatically adjustable in height and because it lifts up when switched off, scratches on the product are prevented. The brush units are equipped with electrical compensation to avoid brushing into the conveyor belt. With the intuitive touchscreen, you can seamlessly adjust the speed of the conveyor belt, brushes, and grinding belt, making every finish result achievable. The machine is equipped with automatically adjustable programs for effortless repetition of operation combinations and offers optional automatic brush calibration and QR code scanner for even more ease of use. All operating stations are fully automatic adjustable for an optimal user experience. With the latest software and full integration possibilities with handling and ERP systems

Key Features:

First Station (Grinding Unit): Removes burrs and ensures a flat, burr-free surface.

Second Station (Oscillating Disc Brushes): Four brushes apply light pressure to ensure rounding of inner and outer contours.

Final Operation (Multibrush): Provides the final finishing touch, ensuring the product has a perfect, high-quality finish.

Main Technical Parameters:

| Parameter | Value |

| Processing Width | ≤ 600mm |

| Processing Thickness | 1 ~ 80mm |

| Minimum Processing Size | 50mm x 50mm |

| Total Machine Power | ≤ 33.95KW (excluding dust extraction) |

| Sand Belt Size | 1910 x 600mm |

| Steel Hammer Brush Diameter | Φ 162mm |

| Conveyor Speed | 0.5~6 m/min (adjustable) |

| Sand Belt Linear Speed | 18 m/s |

| Processing Thickness Servo Adjustment Accuracy | 0.01mm |

| Grinding Consumables | Steel hammer brush + abrasive belt |

| Dust Extraction Volume | 4000 m³/h |

| Approximate Equipment Dimensions | 2700mm (L) x 1600mm (W) x 2100mm (H) |

| Approximate Machine Weight | 2.2T |

This machine provides an efficient and reliable solution for deburring, edge rounding, and surface finishing, ensuring high-quality results and consistent performance for various metal parts. It is ideal for industries requiring precise and high-speed processing.