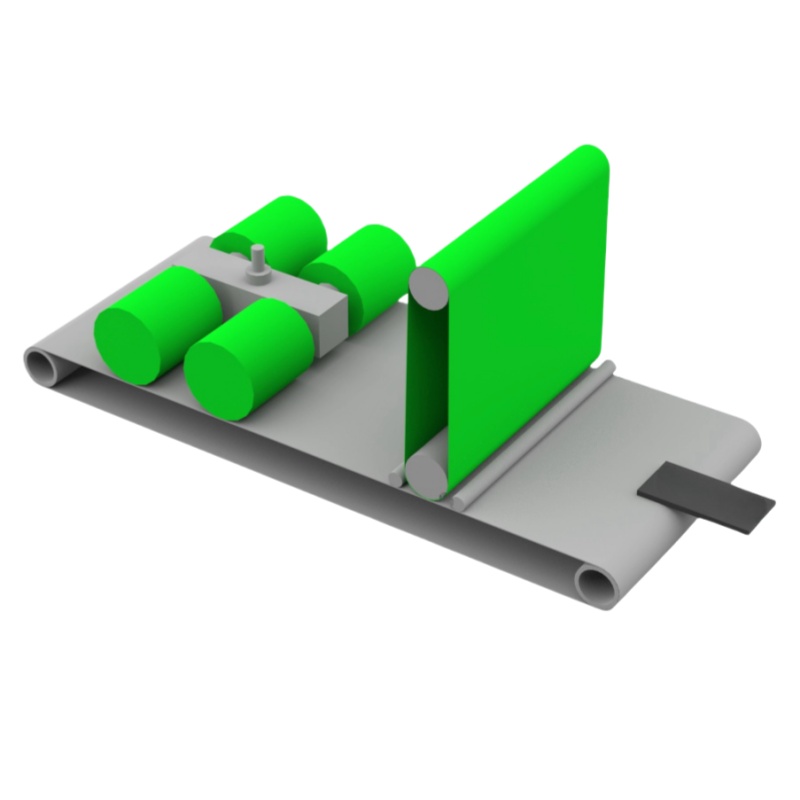

A metal sander deburring machine for edge rounding equipped with 4 flap wheels and a grinding belt is designed to efficiently remove burrs, round sharp edges, and finish metal surfaces with precision. This type of machine is typically used for deburring metal parts after cutting, punching, laser cutting, or shearing.

Machine Overview:

This machine combines flap wheels and a grinding belt to handle a variety of metal deburring and edge rounding tasks. The flap wheels are ideal for polishing and smoothing the edges of metal parts, while the grinding belt is used for more aggressive material removal and surface finishing. The combination of these tools makes the machine versatile for different deburring and edge rounding needs.

Key Features:

4 Flap Wheels:

The machine is equipped with 4 flap wheels which are ideal for fine deburring and polishing.

These flap wheels help to smooth edges, remove small burrs, and polish surfaces without excessive material removal.

Each flap wheel can be used independently to target specific areas on the workpiece.

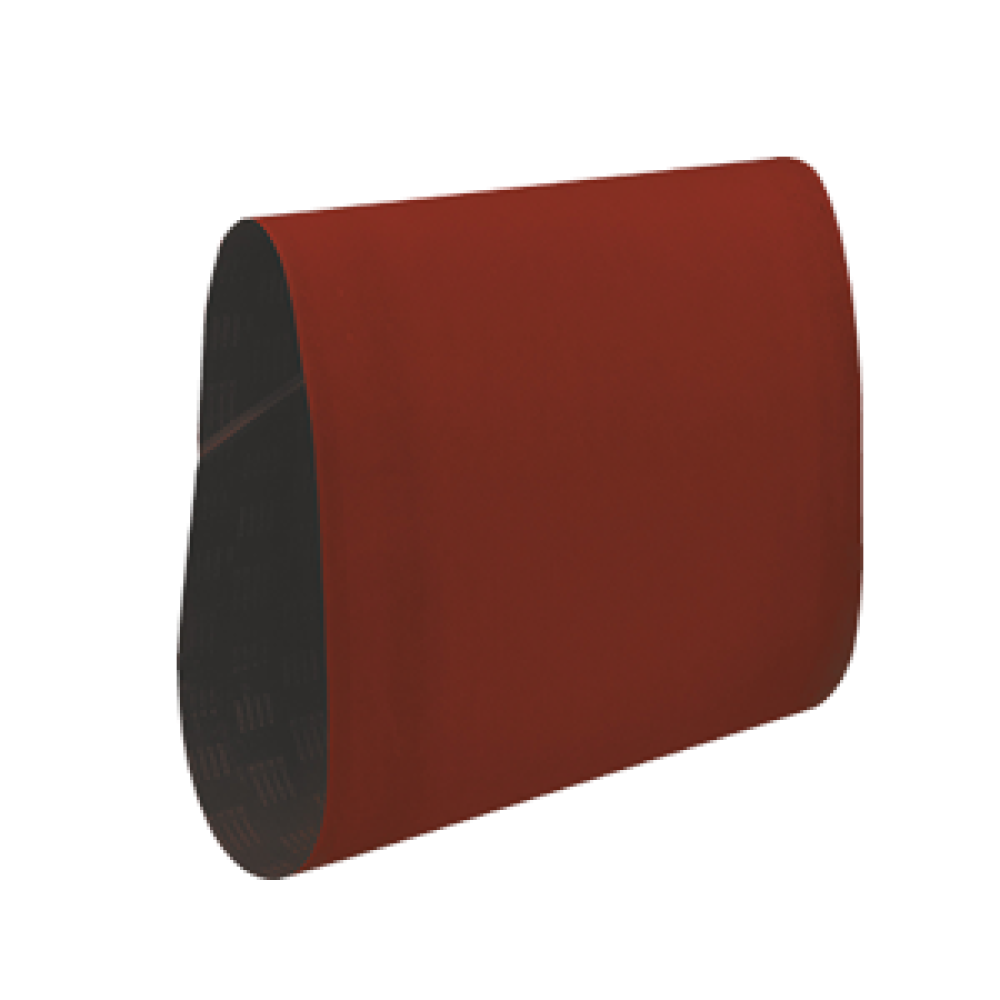

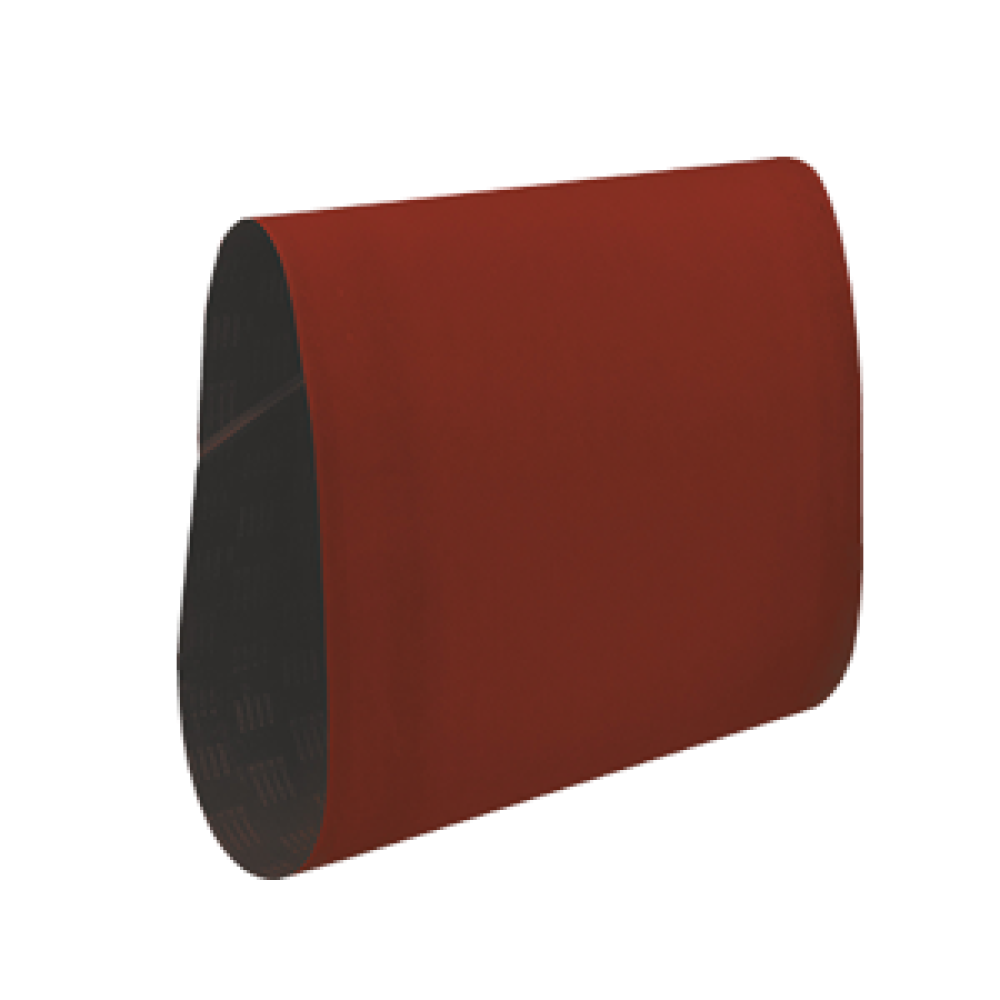

Grinding Belt:

The grinding belt allows for more aggressive deburring and edge rounding.

It is suitable for heavy material removal, especially for thicker metal parts.

The belt can be adjusted to control the pressure and speed, ensuring precise material removal.

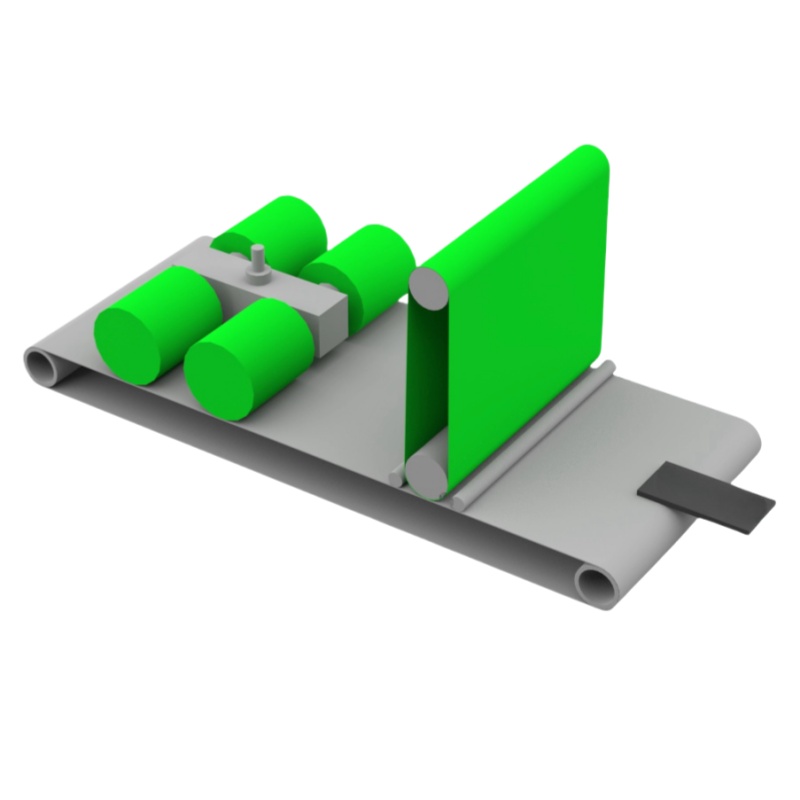

Edge Rounding:

The machine is specifically designed to round sharp edges, improving safety and the aesthetic appearance of metal parts.

The flap wheels and grinding belt work together to provide a smooth, rounded edge finish.

Adjustable Feed Speed:

The feed speed of the workpieces can be adjusted to achieve different surface finishes.

Faster feed speeds are suitable for high-volume production, while slower speeds allow for more detailed work.

Dust Extraction:

Versatility:

The combination of flap wheels and a grinding belt allows the machine to process a wide range of materials including stainless steel, aluminum, carbon steel, and other non-ferrous metals.

It is ideal for deburring, edge rounding, and surface finishing for parts such as metal sheets, tubes, and components.

Applications:

Deburring: Removing burrs left from processes like laser cutting, punching, shearing, and plasma cutting.

Edge Rounding: Rounding the sharp edges of metal parts, improving safety and functionality.

Surface Finishing: Smoothing metal surfaces for better appearance and preparation for further treatment (e.g., painting or coating).

Polishing: Achieving a smooth and polished finish on metal parts.

Automated Metal Processing: Ideal for high-volume production environments where metal parts need consistent, high-quality finishes.

Applications in Industries:

Metal Fabrication: For general metal sheet deburring and edge rounding.

Automotive: Deburring and edge rounding of automotive components.

Aerospace: Ensuring the safety and quality of metal parts used in aerospace applications.

Manufacturing: Any industry where metal parts require clean, smooth edges to ensure proper fit and function.

Conclusion:

The metal sander deburring machine with 4 flap wheels and a grinding belt is a highly effective solution for deburring, edge rounding, and finishing metal parts. It offers both precision and efficiency, making it ideal for industries requiring high-quality edge treatment and surface finishing. Whether for stainless steel, aluminum, or carbon steel, this machine is capable of handling a wide range of applications.

Technical Specifications:

| Parameter | Specification |

| Working Width | 800mm |

| Deburring and Rounding Tools | 4pcs Flap Wheel + Grinding Belt |

| Max Part Size | 800mm x 80mm (width x thickness) |

| Belt Speed | 10-20 m/s |

| Motor Power | 15kW (total) |

| Feeding Speed | Adjustable from 0.5 - 6m/min |

| Dust Extraction Connection | 100mm Ø (for dust collection) |

| Control Panel | PLC-based with digital interface |

| Power Supply | 380V, 50Hz |

| Machine Dimensions (LxWxH) | 2200mm x 1000mm x 1400mm |

| Weight | 2200 kg |

| Material Types | Carbon Steel, Stainless Steel, Aluminum, Non-Ferrous Metals |

| Safety Features | Emergency stop, overload protection, safety covers |