1. Main Processing Range of the Equipment

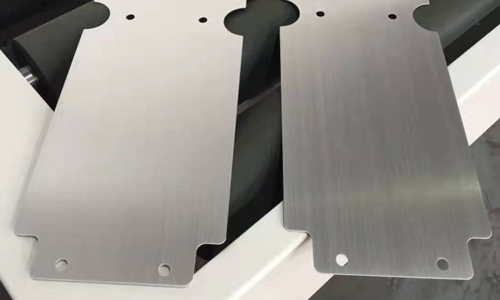

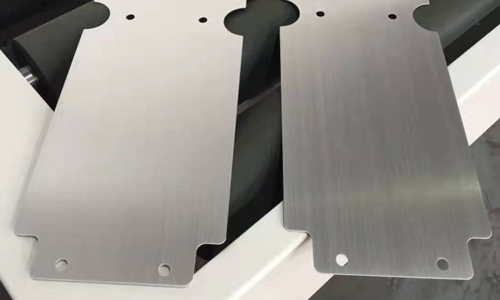

1. Processed Products: Carbon steel plates, etc.

2. Equipment Functions:

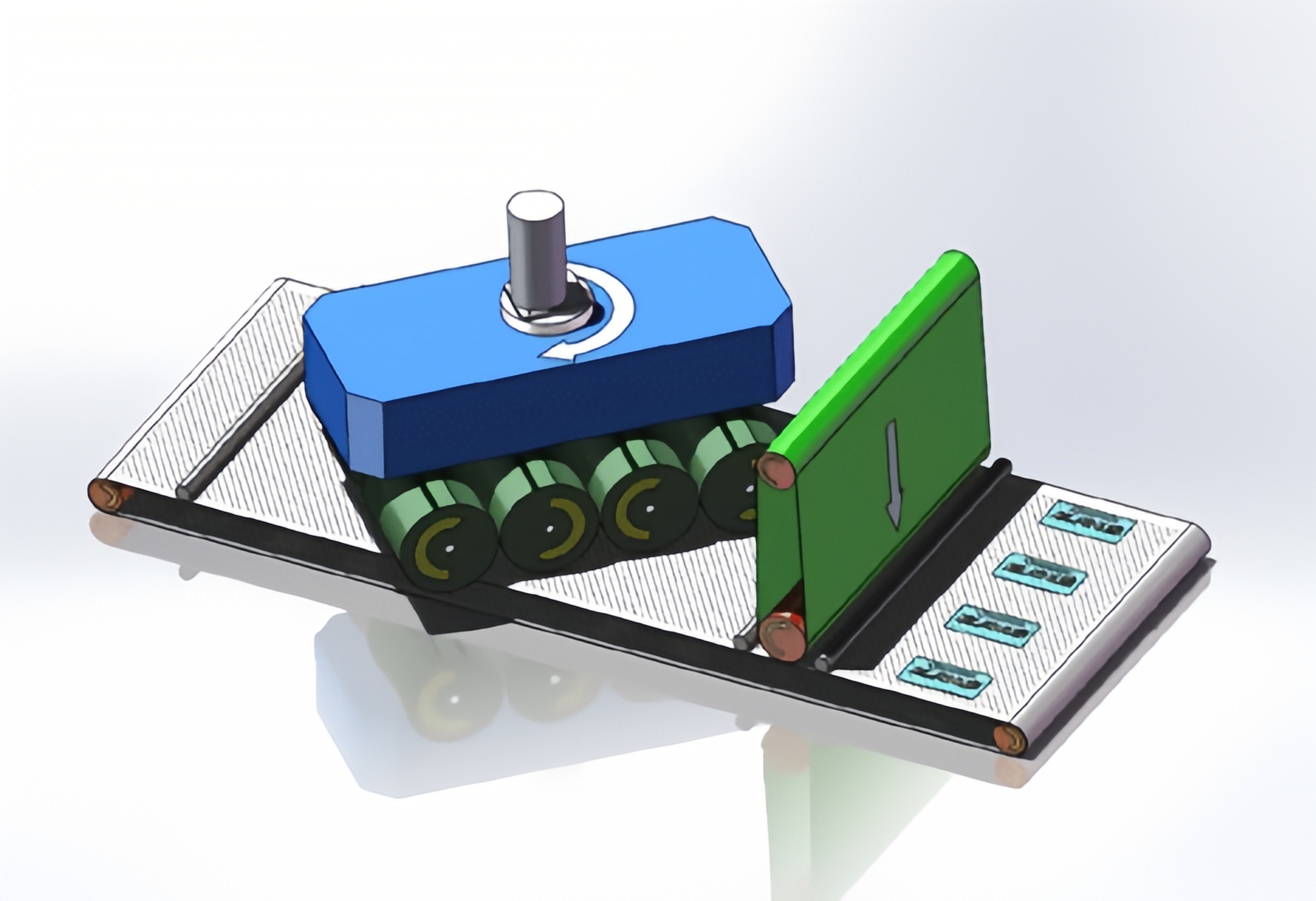

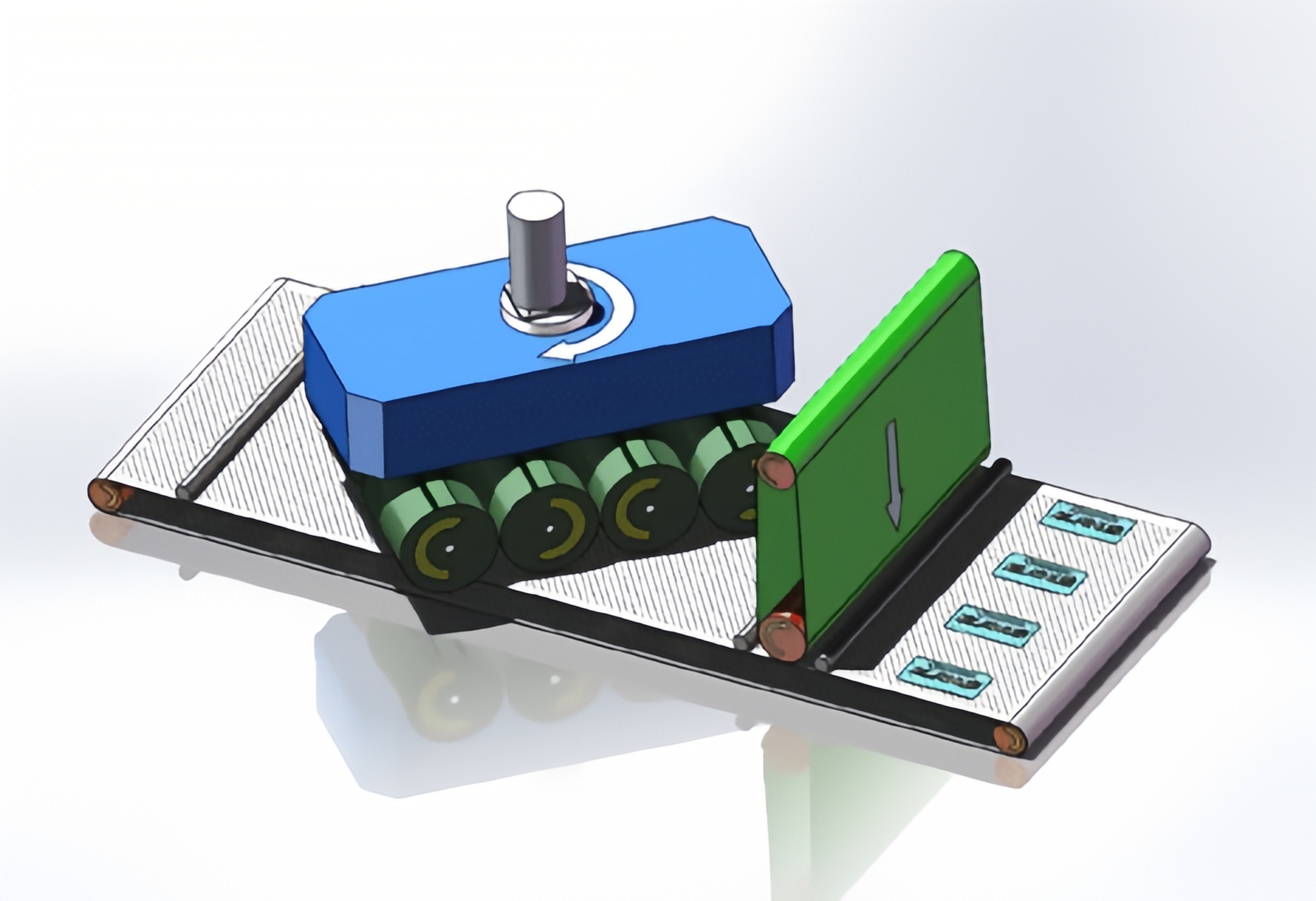

This equipment is a dry-type combination machine with one set of steel hammer disc brushes, one set of horizontal sanding belts, and one set of planetary roller brushes. It is primarily used for processing the edges, holes, and surface treatments of metal plates, such as removing slag, wire drawing, deburring, and polishing.

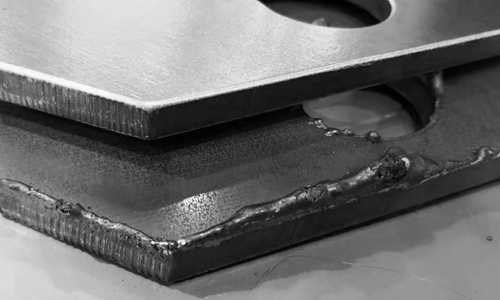

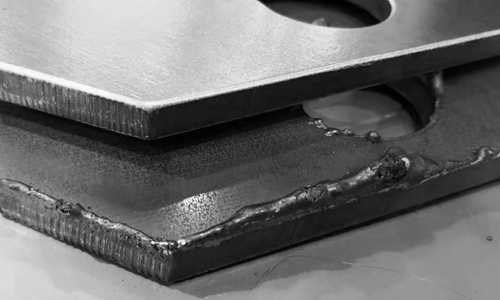

The machine can fully remove burrs produced during processes like drilling, stamping, shearing, laser cutting, plasma cutting, flame cutting, etc., in one pass. It ensures all edges and holes of the workpieces have a small R radius. The processing is safe, reliable, and ensures the workpiece reaches perfect quality.

2. Working Principle of the Equipment

The equipment first uses a set of horizontally oscillating steel hammer disc brushes to knock off slag particles and burrs from the workpiece surface. It then uses a horizontal sanding belt to remove any residual burrs and polish the surface. Next, a planetary roller brush station (composed of 4 sets of universal sanding disc rollers, with adjacent sanding discs rotating in opposite directions and the entire brush set rotating in orbit) applies high-speed centrifugal forces (grinding, scraping, shaving, etc.) on the edges and holes of the workpiece, removing burrs without any dead spots.

The system produces uniform R-radius edges (size of R-radius can be adjusted by selecting different processes and abrasive materials) without affecting the precision of the workpiece. During the entire process, the machine does not damage the dimensions or accuracy of the workpiece.

Additionally, the steel hammer station, sanding belt station, and sanding roller brush station can operate independently:

The steel hammer station can independently remove slag from the workpiece edges.

The sanding belt station can independently perform surface wire drawing, polishing, and deburring on metal plates.

The sanding roller brush can independently perform 360-degree burr removal, especially for laser-cut and CNC punched parts, ensuring complete burr removal without damaging any protective film. It will not scratch the sheet metal surface. The use of special soft abrasive filaments designed for burr removal ensures that the machine can effectively deburr without harming the workpiece surface (even when a protective film is applied).

The workpieces are securely fixed by a strong permanent magnetic conveyor system, which supports workpieces larger than 50mm x 50mm for through-processing without additional tooling. The conveyor system has variable frequency speed control.

The machine is equipped with a wet dust collection system to reduce safety hazards and efficiently handle grinding dust. A high-pressure, high-flow fan system draws the dust into a dust collection chamber, where water spray helps settle the dust. The filtered clean air is then discharged into the atmosphere, improving the working environment for operators. The system also recycles grinding metal powder, ensuring an environmentally friendly production process.

Advantages of Using the Equipment:

Increased Production Efficiency: Continuous feeding and through-processing meet high-volume order requirements.

Improved Product Quality: The consistency of processed workpieces is excellent, with surface treatment results far surpassing manual processing.

Cost Savings: The processing cost per unit area is much lower than manual treatment.

Safety and Environmental Protection: Dust absorption ensures a safe working environment, improving worker safety and working conditions.

Main Technical Parameters of the Equipment:

Processing Width: ≤800mm

Processing Thickness: 0.5~80mm

Minimum Workpiece Size: 50mm x 50mm (Carbon steel)

Total Power: 20.25kW

Steel Hammer Disc Brush Size: Φ162mm

Sanding Belt Size (60# Zirc-Alumina): Φ3530mm x 80mm

Sanding Roller Brush Size (120# Abrasive, Germany Künzle & Tasin): Φ300mm x 300mm

Conveyor Feed Speed: 0.5~6m/min (Variable Frequency Control)

Sanding Belt Line Speed: 12m/s

Roller Brush Self-Rotation Speed: 8~26m/s (Variable Frequency Control)

Roller Brush Orbital Speed: 1~15r/min (Variable Frequency Control)

Number of Roller Brush Planetary Axles: 1

Number of Roller Brush Self-Rotation Axles: 4

Processing Thickness Servo Adjustment Precision: 0.01mm

Roller Brush Compensation Servo Adjustment Precision: 0.01mm

Grinding Consumables: Steel hammer disc brushes + sanding belts + roller brushes

Conveyor Worktable Load Capacity: ≤400kg

Dust Collection Airflow: 5000m³/h

Machine Dimensions: Length 4100mm x Width 1900mm x Height 2200mm

Machine Weight: Approximately 3 tons

Consumables List:

| Item Name | Specifications/Model | Quantity | Estimated Service Life |

| Rubber Conveyor Belt | Φ8600mm x 800mm | 1 piece | 6000-20000 hours |

| Sanding Belt Backing | Φ3340mm x 80mm | 1 piece | 300-1000 hours |

| Grinding Graphite Pads | 70×30×10mm | 30 pieces | 300-1000 hours |

| Steel Hammer Disc Brush | Φ162mm | 6 pieces | 3000-10000 hours |

| Zirconia Alumina Sanding Belt | Φ3530mm x 80mm | 1 piece | 8-40 hours |

| Universal Roller Brushes | Φ300mm x 400mm | 4 pieces | 1000-3000 hours |

Installation Requirements:

Sufficient horizontal installation space (4m x 5m).

380V, 50Hz power supply (±10%).

Clean compressed air supply.

Documentation Included (2 copies of the user manual):

Mechanical schematic diagram.

Electrical schematic diagram.