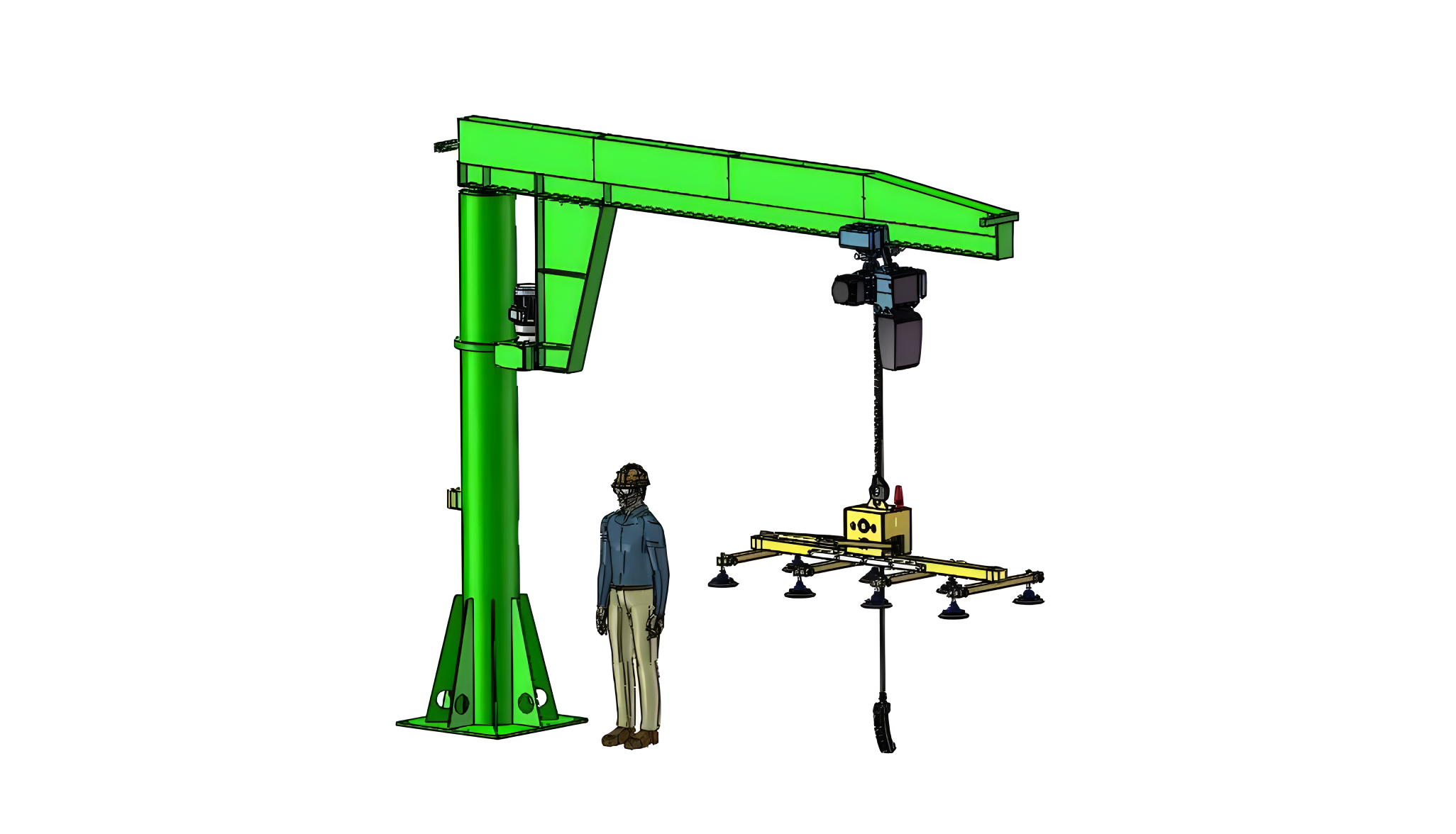

Battery-Powered Vacuum Lifter for Fiber Laser Cutting Machine loading and unloading is designed specifically to automate the handling of metal sheets, reducing manual labor and enhancing operational efficiency. This equipment is ideal for industries that use fiber laser cutting machines, as it streamlines the material handling process for sheet metal.

Key Features of a Battery-Powered Vacuum Lifter for Fiber Laser Cutting Machines:

Battery-Powered Operation:

Runs on rechargeable batteries, typically DC12V systems, offering portability and eliminating the need for a constant power supply. This makes it flexible for environments where electrical outlets may not always be available near the machine.

Easy Integration with Fiber Laser Cutting Machines:

Suction Cup Configuration:

Equipped with multiple suction cups, usually 6 to 8, with diameters ranging from 150mm to 200mm, depending on the weight and size of the sheet metal being handled.

The suction cups are distributed to maximize surface contact, ensuring the sheet is lifted securely and safely without causing any damage.

Load Capacity:

Sheet Size Compatibility:

Compact Design:

Rotational Flexibility:

Safety Features:

Built-in alarms for low battery levels and emergency stop buttons are common in battery-powered models to ensure safe operation.

Vacuum pressure monitors ensure that the sheet is gripped firmly before lifting, reducing the chance of drops or accidents.

Quick Recharge System:

Advantages of Using Battery-Powered Vacuum Lifters for Laser Cutting Machines:

Enhanced Efficiency:

Reduced Labor Costs:

Portable and Versatile:

Safe Handling:

Compatibility with Multiple Materials:

These lifters can handle various metal types such as carbon steel, stainless steel, aluminum, and non-ferrous materials commonly used in laser cutting processes.

Typical Specifications:

Load Capacity: 300-800 kg

Suction Cup Diameter: 150-200mm

Number of Suction Cups: 6-8 cups

Sheet Size Range: 2000×1000mm to 4000×2000mm

Power Supply: Battery-powered (DC12V)

Control Options: Wireless or wired remote control for operator convenience

Charging Time: Typically 6-8 hours for a full charge, with some models offering fast charge options

Applications:

Laser Cutting: Automating the loading and unloading of metal sheets in fiber laser cutting systems.

Sheet Metal Fabrication: Useful for various metal handling tasks, not only in laser cutting but also in punching, stamping, or bending machines.

Warehousing and Inventory: Efficient for moving sheets to and from storage areas in metalworking facilities.

Safety Considerations:

Anti-Drop Mechanism: In case of battery failure, most battery-powered vacuum lifters are equipped with safety features that prevent the sheet from dropping unexpectedly.

Vacuum Sensors: Integrated vacuum sensors that alert the operator if suction levels drop below safe limits.

Recommended Models:

If you need specific recommendations for available models, it is worth looking into manufacturers like ANVER, Schmalz, Vaculex, or GGR Group, who offer a variety of battery-powered vacuum lifters designed for laser cutting applications. Each model comes with customizable options based on your specific sheet size, weight, and operational needs.

Pneumatic Vacuum Lifter

| Product Model | JS-300-2M/3M |

| Rated Load (kg) | 300 |

| Suction Cup Diameter (mm) | 150 |

| Number of Suction Cups | 8 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 |

| Working Voltage | 0.8 MPa Air Supply |

Battery-Powered Vacuum Lifter

| Product Model | JS-JG300-2M/3M | JS-JG600-2M/3M | JS-JG800-2M/3M |

| Rated Load (kg) | 300 | 600 | 800 |

| Suction Cup Diameter (mm) | 150 | 150 | 150 |

| Number of Suction Cups | 8 | 6 | 6 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 | Same as JS-JG300-2M/3M | Same as JS-JG300-2M/3M |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 | Same as JS-JG300-2M/3M | Same as JS-JG300-2M/3M |

| Working Voltage | DC12V | DC12V | DC12V |

Plug-In Vacuum Lifter

| Product Model | JS-GC300-2M/3M | JS-GC600-2M/3M | JS-GC800-2M/3M |

| Rated Load (kg) | 300 | 600 | 800 |

| Suction Cup Diameter (mm) | 150 | 200 | 200 |

| Number of Suction Cups | 8 | 8 | 8 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 | Same as JS-GC300-2M/3M | Same as JS-GC300-2M/3M |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 | Same as JS-GC300-2M/3M | Same as JS-GC300-2M/3M |

| Working Voltage | AC220V/380V | AC220V/380V | AC220V/380V |