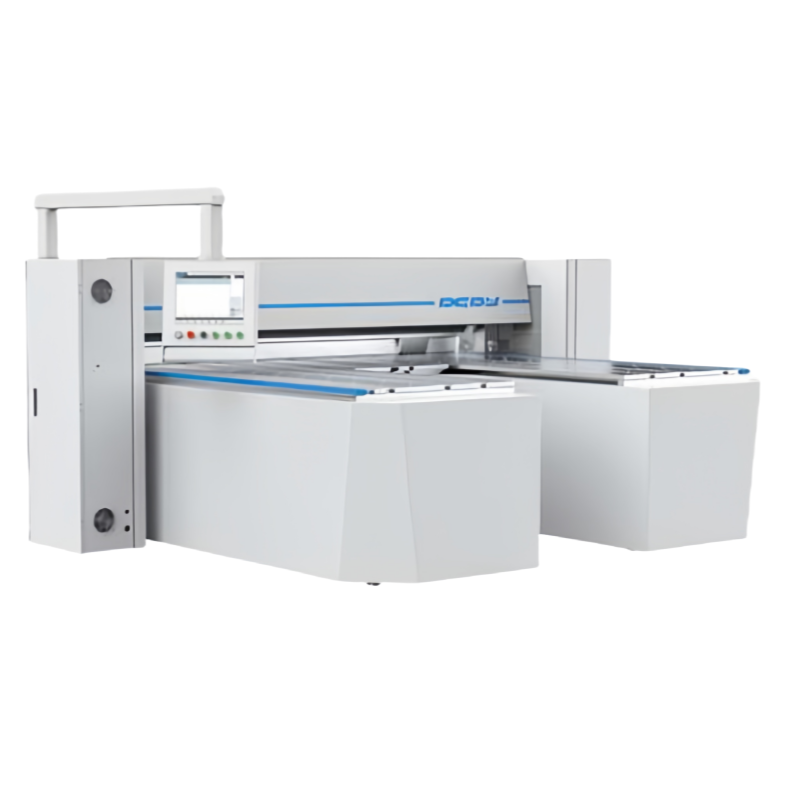

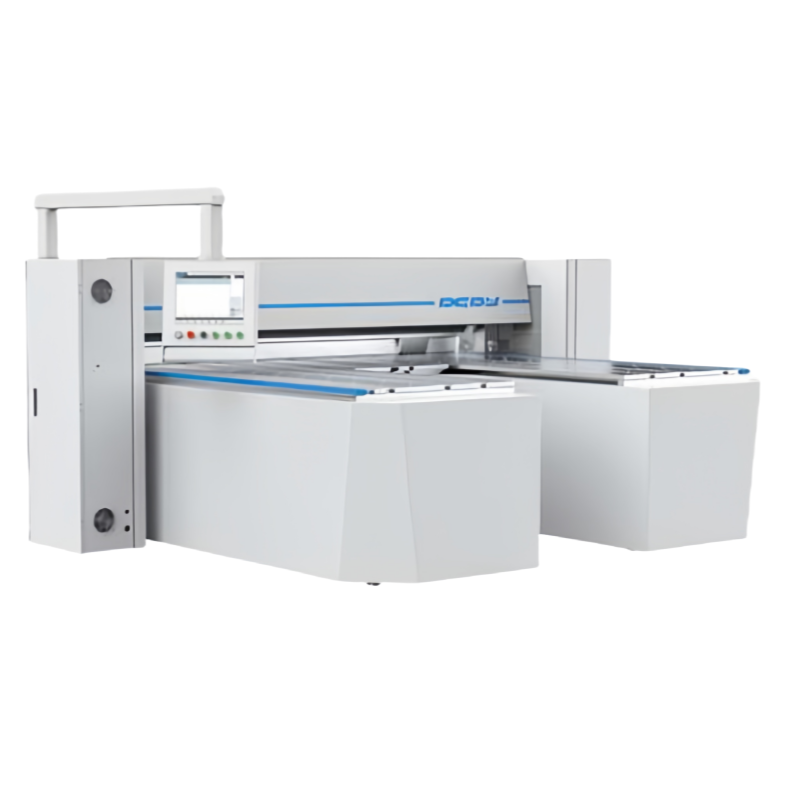

4100mm Sheet Metal Folding Machine is designed for handling long sheets of metal, ideal for industries that work with large metal panels such as construction, automotive, and aerospace. Here’s a general overview of such machines:

Key Features of a 4100mm Sheet Metal Folding Machine:

Bending Length:

Material Compatibility:

Suitable for carbon steel, stainless steel, aluminum, and other metals.

Machines often have varying capacities depending on the material's thickness, commonly up to 2mm for steel and 1.5mm for stainless steel.

Servo Motor Precision:

Servo motors provide high accuracy and speed during the bending process, ensuring consistent results across large parts.

The servo-driven mechanism allows for finer control over angles and bending forces, reducing material waste and enhancing precision.

Adjustable Tooling:

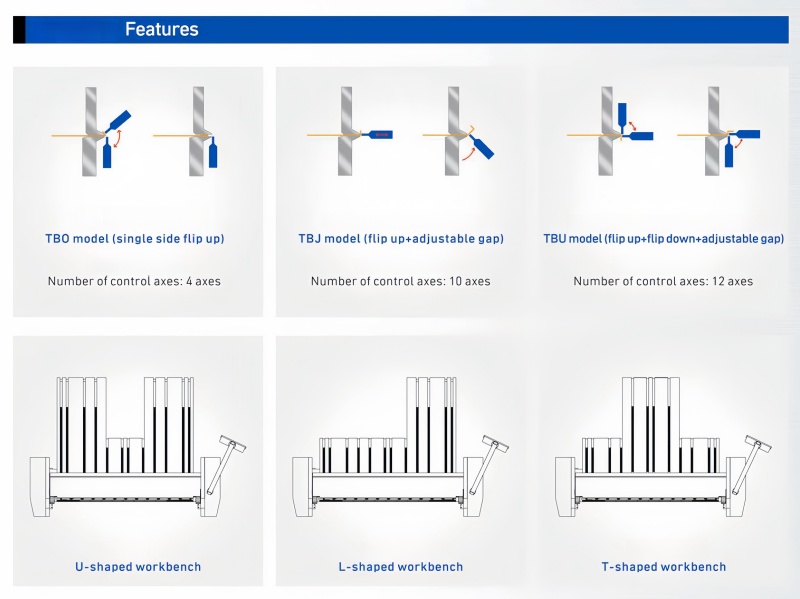

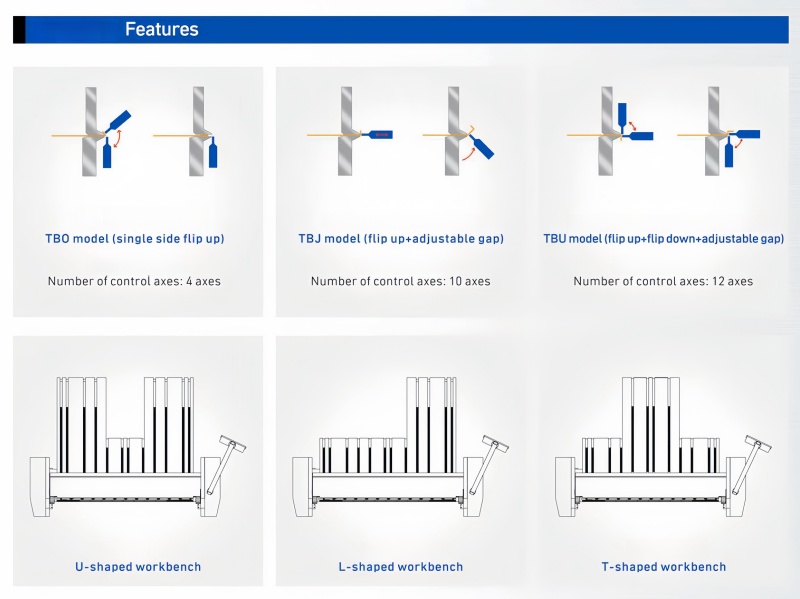

Multi-axis Control:

Automation:

Many 4100mm folding machines come with CNC systems for programmable folding sequences, allowing automation of repetitive tasks and high production volumes.

Offline and online programming features enable users to pre-program bending operations, enhancing productivity.

Safety Features:

Energy Efficiency:

Applications:

Construction: Building facades, roofing panels, and architectural elements.

Automotive: Large car body panels, frames, etc.

Aerospace: Aircraft body components.

HVAC: Fabricating large ducts, metal roofing, and structural panels.

Example Specifications:

Max Bending Length: 4100mm

Bending Thickness:

Bending Angle Range: 45° to 180°

Axes Control: 4-6 axes

Power Source: Servo-driven motors (Energy efficient)

Control System: CNC with programmable interface

Safety: Light curtain protection, auto shut-off, emergency stop

Weight: Approximately 8,000 to 11,000 kg depending on the specific model

A 4100mm sheet metal folding machine offers robust performance and flexibility for manufacturers who need to handle large sheets with precision, efficiency, and safety. If you're considering purchasing such a machine, make sure to focus on factors such as motor capacity, CNC control features, and the available tooling to meet your specific manufacturing needs.

Technical Parameter

| Item | Unit | TB025 | TB032 | TB041 | TBJ25 | TBJ32 | TBJ41 | TBU25 | TBU32 | TBU41 |

| Bending thickness (carbon steel) | mm | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Bending thickness (stainless steel) | mm | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Bending angle range | degrees | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | -45...+45 | -45...+45 | -45...+45 |

| Max. bending length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Rear positioning length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Open height | mm | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Bending tool height | mm | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 |

| Control axis number |

| 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Pressing speed | mm/s | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Bending speed | m/s | 5.0 | 5.0 | 5.0 | 6.5 | 6.5 | 6.5 | 7.0 | 7.0 | 7.0 |

| Motor energy consumption | kW | 3.5 | 4.5 | 6.1 | 3.5 | 4.5 | 6.1 | 5.5 | 7.0 | 10.0 |

| External dimensions (L × W × H) | mm | 3100×1650 | 3800×1950 | 5300×2150 | 3100×1650 | 3800×1950 | 5300×2150 | 3100×1650 | 3800×1950 | 5700×2150 |

| Weight | kg | 4500 | 5300 | 7500 | 4500 | 5300 | 7500 | 4900 | 7000 | 11000 |

This table provides information on various models of CNC sheet metal folding machines, highlighting their specifications such as bending thickness, bending angle range, maximum bending length, open height, speed, motor energy consumption, dimensions, and weight.