DC12V battery-powered vacuum lifters are also highly effective for lifting and moving heavy 1000kg metal sheets, including those produced by laser cutting machines. These vacuum lifters can be adapted to handle the challenges of moving large, heavy metal sheets, ensuring a smooth and safe operation without the need for additional personnel or machinery.

Key Features for Lifting 1000kg Metal Sheets:

High Load Capacity: These vacuum lifters can be designed to handle loads up to 1000kg, suitable for large, heavy metal sheets.

DC12V Battery-Powered: The 12V battery provides mobility, eliminating the need for an external power source. This feature is especially useful in environments where a power supply may be limited or where portability is crucial.

Powerful Vacuum System: The vacuum pump generates enough suction to securely lift and move metal sheets without causing damage. It ensures that the sheets remain stable during transport.

Adjustable Suction Pads: The suction cups or pads are often adjustable to fit various sheet sizes and thicknesses, making them versatile for a range of metal sheet dimensions.

Safety Features: Features such as a built-in vacuum gauge, emergency stop button, and automatic shut-off in case of low suction power provide additional safety and reliability during use.

Rugged Design: The lifters are often built with durable materials like steel or aluminum to ensure they can withstand the heavy loads and harsh industrial environments.

Benefits for Handling Metal Sheets:

Improved Efficiency: The battery-powered vacuum lifter allows workers to move large sheets of metal quickly and safely, improving overall workflow and productivity.

Reduced Risk of Injury: Lifting heavy metal sheets manually can be dangerous. Vacuum lifters help eliminate the risk of injury from manual handling.

Precise Handling: The lifters provide precise control when placing or repositioning metal sheets, reducing the likelihood of damage or misplacement.

Versatility: Can be used for sheets cut by laser machines, as well as those produced by other methods like plasma cutting, shearing, or stamping.

Potential Applications:

Laser Cut Metal Sheets: Specifically designed for handling sheets produced by laser cutting, which are often thin, delicate, and prone to warping.

Metal Fabrication: Ideal for use in metal fabrication shops, especially those working with large and heavy steel or aluminum plates.

Construction and Assembly: Used in construction or manufacturing environments for lifting metal sheets that are part of larger assemblies, such as in shipbuilding or automotive manufacturing.

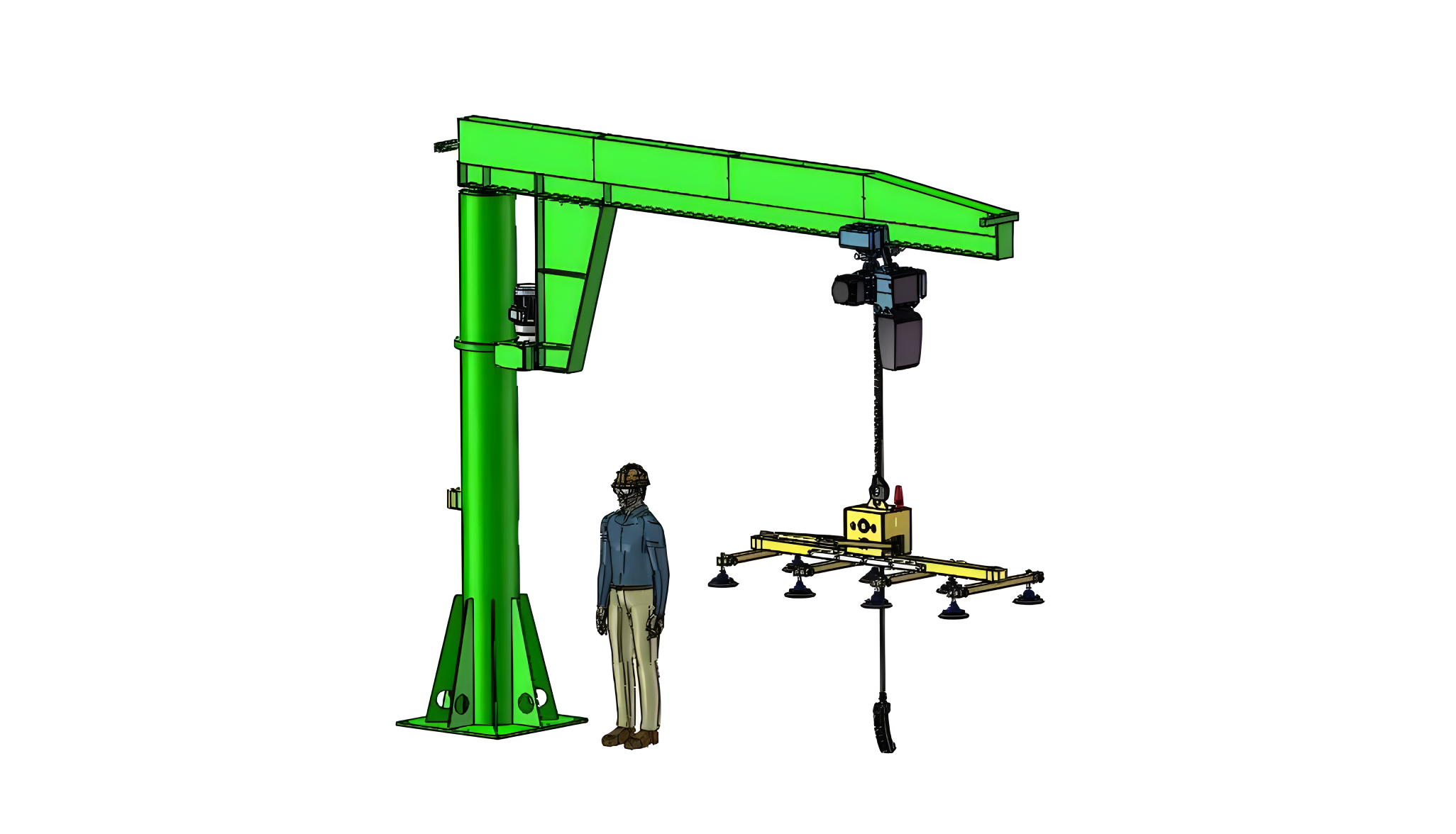

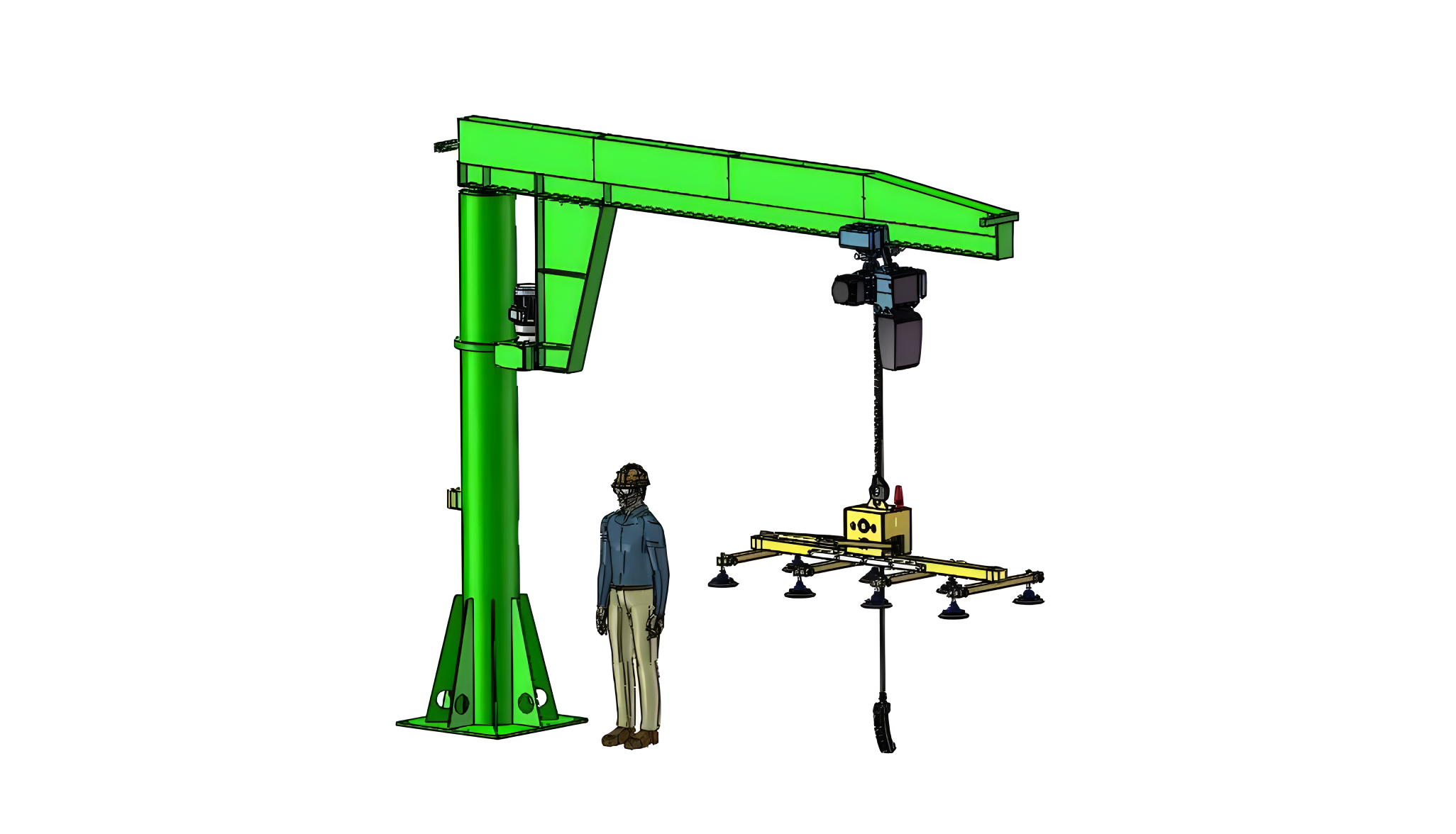

Vacuum Lifter

| Product Model | JS-J1000-5M | JS-C1000-5M |

| Rated Load (kg) | 1000 | 1000 |

| Suction Cup Diameter (mm) | 200 | 200 |

| Number of Suction Cups | 12 | 12 |

| Outer Dimensions (mm) | 5000*1000 | 5000*1000 |

| Plate Dimensions (mm) | 6000*2000 | 6000*2000 |

| Working Voltage | DC12V | 380V/220V |

Typical Equipment Applications:

Sheet Metal Processing Industry: Primarily used for loading and unloading sheets in laser cutting, stamping, bending, and other processes.

Metal Processing Plants: Suitable for bulk handling and stacking of metal sheets, especially during long-term, high-frequency operations, where automated equipment can effectively reduce errors and waste.

Home Appliance Manufacturing: Automated handling equipment can be used for transporting materials like refrigerator, washing machine, and air conditioner shells, enhancing the level of automation in production lines.

Automotive Manufacturing: In the processing of automotive body panels, automatic stacking and handling equipment ensures the safe transport of large sheet metal parts.