DP-WS200W Laser Jewelry Welding Machine-200W gold silver jewelry repairing machine welders

DP-WS200W Laser Jewelry Welding Machine-200W gold silver jewelry repairing machine welders

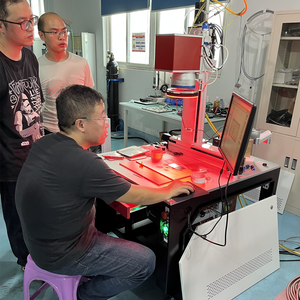

Metal jewelry laser welding machine is mainly used for repairing holes, spot welding trachoma and repairing welding of gold and silver jewelry. It is suitable for gold, silver, platinum, stainless steel, titanium and other heavy metals and their alloy materials. Welding of precision devices such as battery nickel strips, integrated circuit leads, watch hairsprings, picture tubes, electron gun assembly and other fields.

Metal Jewelry Welding

Jewelry is indispensable in people's life at the moment, and suitable or good-looking jewelry will also show a different temperament, and the world's famous jewelry brands Tiffany, Tijue, Mikimoto, Derry, Demia Nepal, Boucheron, Van Cleef & Arpels, Harry Winston, Cartier, and Bulgari are favored by the masses. Their design style is bold and unique. The whole piece is very noble and exquisite, and the details are also ingenious. Almost everyone knows about their popularity in the global market. They are also jewelry brands. Why can their workmanship be so good? , and even international brands, of course, the credit of the jewelry laser welding machine is indispensable.

Metal jewelry laser welding machine welding features:

● The core component "laser condenser cavity" adopts imported ceramic or metal reflection condenser cavity, which has more stable performance and longer service life, bringing users an efficient and economical processing solution;

● The welding speed is fast, the welding efficiency is significantly improved, the welding time of a single workpiece is greatly shortened, and the investment return period is accelerated for customers;

● The welding quality is high, the welding seam is beautiful, the welding seam can be as strong as the base metal, and no secondary processing is required, which effectively improves the qualified rate of finished products;

● Weldable refractory materials, especially suitable for precision welding of tiny parts and jewelry;

● Strong ability to customize special planes, and can tailor-made exclusive models according to customer requirements.

Laser welding is seamless welding without external force; when welding, no electrodes are used, the entire welding process is non-contact, and there is no concern about electrode pollution and damage. It can also achieve vacuum environment welding, and can pass glass or be transparent to the beam The laser beam can be focused on a small area, and small and closely spaced parts can be welded; High-speed welding can be achieved under automation, and it can also be digitally or computer controlled to achieve precision machining, and every detail is meticulous.