The Mechanical Compensation Device for press brakes is used to compensate for errors caused by mechanical deformation or pressure during the bending process. These devices ensure precision and consistency throughout the bending operation, improving the accuracy and productivity of the press brake.

Main Functions and Principles of the Mechanical Compensation Device:

Compensation for Material Deflection: During the bending process, the material will deform under force, especially with thicker metal sheets, leading to uneven bending angles. The mechanical compensation device adjusts the mechanical components’ pressure or position to compensate for this material deformation, ensuring precise and consistent final bending angles.

Eliminating the Impact of Workpiece Deformation: As bending pressure is applied, the machine's components such as the upper and lower beams, sliders, and pressurizing units may undergo elastic or plastic deformation. The mechanical compensation device compensates for the effect of these deformations on the workpiece, ensuring accuracy.

Improving Bending Precision: By applying precise mechanical compensation, errors caused by machine component deformation are minimized, especially during complex or multi-stage bending operations, enhancing overall processing accuracy.

Common Types of Mechanical Compensation:

Pressure Plate Compensation: This type uses pressure plates mounted on the workbench or slider to adjust force, ensuring that material deformation is effectively compensated under varying pressure conditions.

Hydraulic Compensation: Some press brakes use hydraulic systems to compensate for material deflection by adjusting the height or pressure of the workbench, achieving compensation.

Spring Compensation: This uses the elasticity of springs to automatically adjust the pressure distribution and provide compensation within a certain range.

Optimizing the Bending Process: Mechanical compensation devices reduce human intervention, lowering the difficulty for operators while significantly increasing the overall efficiency of the press brake. This is particularly beneficial for mass production, ensuring consistency and stability.

Advantages of Mechanical Compensation Devices:

Improved Product Consistency: They maintain consistent bending angles, avoiding errors caused by mechanical deformation.

Enhanced Bending Precision: The compensation device significantly improves the precision when bending thick metal sheets, ensuring high product quality.

Increased Equipment Stability: By compensating for internal deformation of the machine, the service life of the press brake is extended.

Simplified Operation: With less manual adjustment and greater automation, operator errors are reduced.

Understanding Components of The Press Brake

Understanding Components of a Press Brake

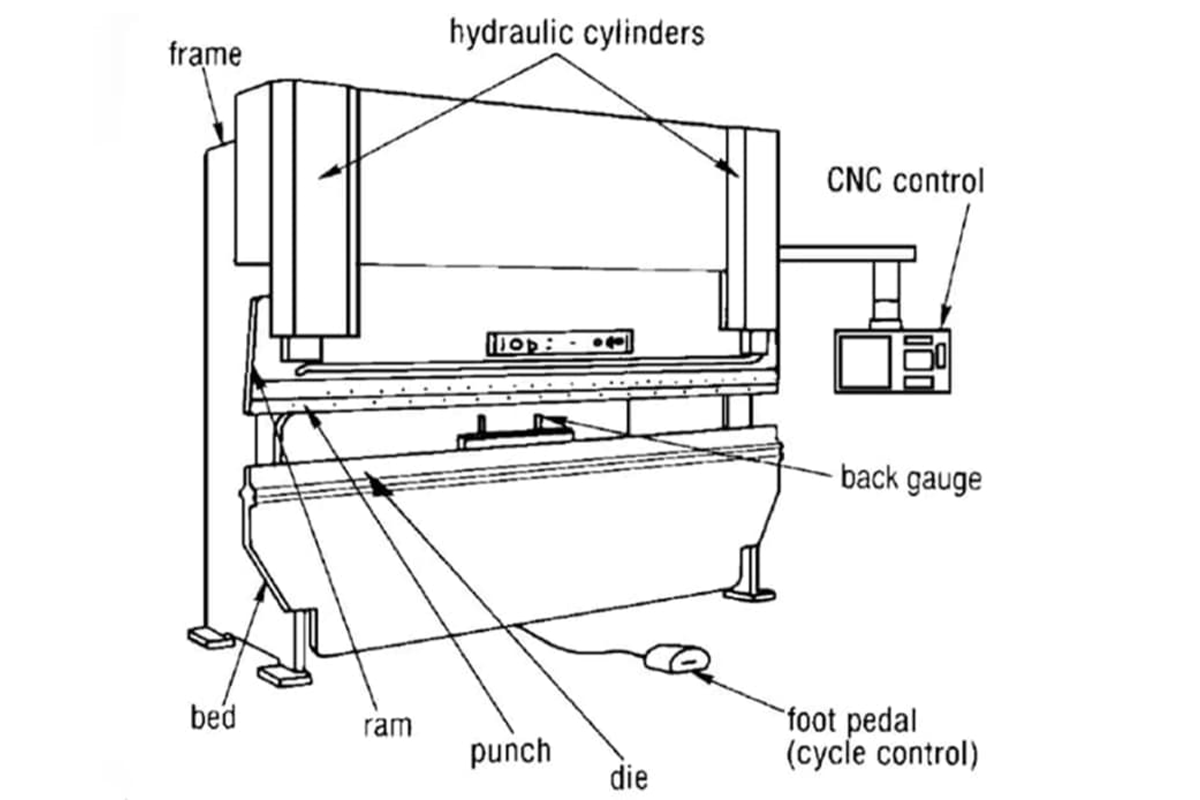

A press brake is a machine tool used for bending sheet metal into various shapes. Below is a detailed explanation of its key components and their functions:

1. Frame

The frame forms the structural foundation of the press brake, providing stability and rigidity during operation. It is crucial for consistent bending results and ensures the machine can withstand the high forces involved without distortion.

Types:

C-Shaped Frame: Compact and suitable for smaller, less powerful machines.

Square Frame: Rigid and designed for heavy-duty operations with larger sheets of metal.

2. Bed

The bed is a flat, stationary surface where the workpiece is placed during bending. It ensures proper alignment of the material and supports the bending process.

3. Ram

The ram is a movable upper component that exerts downward force on the workpiece. It is connected to the punch, directly contacting the metal during the bending process.

4. Punch and Die

Punch: A tool with a specific shape mounted on the upper beam to deform the material during bending.

Die: A complementary tool installed on the lower beam, designed to shape the material into the desired form. Together, the punch and die define the final shape of the bent workpiece.

Understanding Components of a Press Brake

A press brake is a machine tool used for bending sheet metal into various shapes. Below is a detailed explanation of its key components and their functions:

1. Frame

The frame forms the structural foundation of the press brake, providing stability and rigidity during operation. It is crucial for consistent bending results and ensures the machine can withstand the high forces involved without distortion.

Types:

C-Shaped Frame: Compact and suitable for smaller, less powerful machines.

Square Frame: Rigid and designed for heavy-duty operations with larger sheets of metal.

2. Bed

The bed is a flat, stationary surface where the workpiece is placed during bending. It ensures proper alignment of the material and supports the bending process.

3. Ram

The ram is a movable upper component that exerts downward force on the workpiece. It is connected to the punch, directly contacting the metal during the bending process.

4. Punch and Die

Punch: A tool with a specific shape mounted on the upper beam to deform the material during bending.

Die: A complementary tool installed on the lower beam, designed to shape the material into the desired form. Together, the punch and die define the final shape of the bent workpiece.

5. Back Gauge

The back gauge is a precision positioning system located at the rear of the press brake.

6. Control Panel

The control panel is the user interface for operating the press brake.

On CNC press brakes, it allows programming of bending angles, material thickness, and complex sequences, improving precision and efficiency.

7. CNC System

The CNC (Computer Numerical Control) system automates press brake movements, including:

This system ensures high precision and simplifies multi-step operations.

8. Upper and Lower Beams

9. Axes

X-Axis: Controls the back gauge's horizontal movement along the press brake length for flange adjustment.

Y-Axis: Controls the vertical movement of the ram or punch for bending operations.

Z-Axis: Adjusts the back gauge's horizontal positioning along the left and right directions.

R-Axis: Controls the back gauge fingers’ vertical movement for complex or multiple bends.

Understanding Components of a Press Brake

A press brake is a machine tool used for bending sheet metal into various shapes. Below is a detailed explanation of its key components and their functions:

1. Frame

The frame forms the structural foundation of the press brake, providing stability and rigidity during operation. It is crucial for consistent bending results and ensures the machine can withstand the high forces involved without distortion.

Types:

C-Shaped Frame: Compact and suitable for smaller, less powerful machines.

Square Frame: Rigid and designed for heavy-duty operations with larger sheets of metal.

2. Bed

The bed is a flat, stationary surface where the workpiece is placed during bending. It ensures proper alignment of the material and supports the bending process.

3. Ram

The ram is a movable upper component that exerts downward force on the workpiece. It is connected to the punch, directly contacting the metal during the bending process.

4. Punch and Die

Punch: A tool with a specific shape mounted on the upper beam to deform the material during bending.

Die: A complementary tool installed on the lower beam, designed to shape the material into the desired form. Together, the punch and die define the final shape of the bent workpiece.

5. Back Gauge

The back gauge is a precision positioning system located at the rear of the press brake.

6. Control Panel

The control panel is the user interface for operating the press brake.

On CNC press brakes, it allows programming of bending angles, material thickness, and complex sequences, improving precision and efficiency.

7. CNC System

The CNC (Computer Numerical Control) system automates press brake movements, including:

This system ensures high precision and simplifies multi-step operations.

8. Upper and Lower Beams

9. Axes

X-Axis: Controls the back gauge's horizontal movement along the press brake length for flange adjustment.

Y-Axis: Controls the vertical movement of the ram or punch for bending operations.

Z-Axis: Adjusts the back gauge's horizontal positioning along the left and right directions.

R-Axis: Controls the back gauge fingers’ vertical movement for complex or multiple bends.

10. Sheet Support Arms

Mounted at the machine's front, these arms support the workpiece during bending, ensuring alignment and reducing operator strain.

11. Housing Brace

A structural component that connects the two driving cylinders on the upper beam, maintaining machine stability.

12. Foot Pedal

Used by the operator to engage the machine's clutch or initiate bending operations.

13. Crank Shaft

In mechanical press brakes, this component transfers the flywheel's energy to the ram, ensuring efficient energy conversion.

Advanced Terminology and Techniques

Bend Allowance

Bend allowance refers to material deformation or elongation required by forming a specific bending angle. It is calculated according to material thickness, bending radium material characteristics, etc.

Bend Deduction

Bend deduction refers to the difference between the sum of the layout dimensions and the total length of the curved part. It shows the length of the consumed material during the bending process.

Bottom Dead Center

The bottom dead center refers to the lowest point the punch or upper beam arrived at during the downward stroke. This is the position of the brake when it is fully closed into the die.

Braking Capacity

Braking capacity refers to the biggest force or tonnage exerted by bending specific material inside the machine's operation restriction.

Clutch

A clutch is a mechanical device used in the press brake. It can be used to connect or interrupt the power transmission from the motor to the punch. It controls the movement and stop of the ram during the bending process.

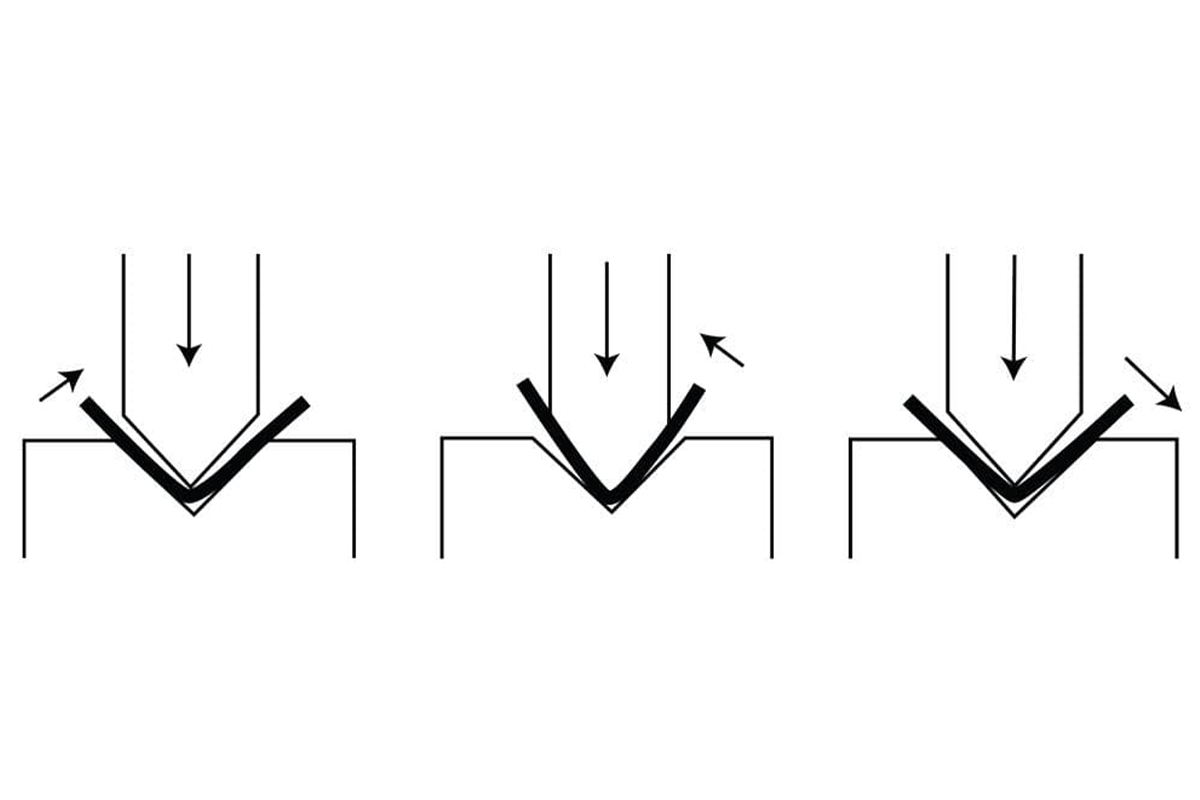

Bottom Bending

Bottom bending is a technique in which the upper beam exerts pressure to bend the material into the complete shape of the die. Compared with air bending, the bottom bending keeps the punch and die closer. Thus, more tools will be in contact with metals, and bending can better match the shape of the punch and die. Bottom bending needs more tonnage than air bending.

Air Bending

Air bending is the most common bending process used in the press brake industry. It is a bending technique that only uses 3 contact lines to bend the material. The bending occurs at three contact points: the punch nose and the shoulders of the die. The material will not arrive at the bottom thus there will be a more flexible and widespread bending angle.

Compared with other bending methods, air bending gets less in touch with the metal. The bending angle is determined by the depth the punch descends into the die instead of the actual shape of the workpiece itself. Operators can counter springback by slightly overbending the material or applying adjustments based on the metal's elasticity and thickness.

Coining

Coining is a precise bending technology. It presses the material into the die to achieve high precision and correct bending angle. Coining originates from the metal manufacturing process for making coins, which uses extremely high tonnage to compress metal, and makes the metal the same as the die’s angle.

| Bending Technique | Advantages | Challenges | Applications |

| Air Bending | Flexible, low tooling cost | Prone to springback | Automotive, custom fabrication |

| Bottoming | Precise, reduces springback | Requires high force, less flexible | Appliances, structural components |

| Coining | Eliminates springback, high precision | High energy and tooling costs | Aerospace, medical devices |

Spring back

Springback is a trend in that material returns to its original shape after being bent. When the material is bent and released, it will show some spring back, resulting in the bending part being slightly straightened or deformed.

Daylight

Daylight refers to the distance between the upper beam and bottom beam of the press brake when it completely opens without material or tools. It determines the maximum height of material that machines and tools can accommodate.

That is the biggest material size that can be put in the machine. The normal daylight ranges from 12-24 inches. Day light through: a term used to describe the maximum open space a brake can open to given a specific die set.

Deflection Compensation

During the bending process, the upper and lower beams of a press brake may flex under the applied force, leading to inaccuracies in the bend angle and shape. Deflection compensation addresses this issue by ensuring even force distribution.

Modern press brakes are equipped with crowning systems. Adjust their crowning system to compensate for deflection, ensuring accurate bending results.

Deflection

Press brake components (such as the upper beam and bottom beam) will be bent and deflected because of exerting forces during the bending process. Deflection will affect the accuracy and repeatability of the bending operation.

Repeatability

Repeatability is the ability of a press brake to return to an exact position consistently over multiple operations. This feature is critical for producing uniform parts, particularly in high-volume production runs. CNC and hydraulic press brakes achieve high repeatability through advanced systems that maintain consistent ram positioning and movement.

Elasticity

Elasticity is a characteristic that can cause the material to be retrieved from its original shape when influenced by the outer force. The press brake machine tool uses material elasticity to achieve the required bending angle.

Elongation

Elongation refers to the amount of material deformation and stretching during the bending process. It is shown by percent and determined by material characteristics and bending parameters.

Flange

Flange refers to the flat or extended part that material remains unbent during the bending operation. It offers stability and can be regarded as a connecting point of the component or structure.

Gibb Adjustment

Gibb adjustment is a process for adjusting the guiding device. The guiding device is a mechanical components that control the press brake punch and frame gap and stability movement.

Inside Bend Radius

The inside bend radius refers to the radius of curvature of the bending material's inner surface. It is measured by the center line to the innermost point of the bend.

Inside Setback

Inside setback refers to the distance between the material edge and the bending line of the bending inner side. It can ensure the correct positioning of the material and achieve accurate bending.

K Factor

The k factor is the modulus used in press brake bending calculation, which is used to ensure neutral axis position and bend allowance. It takes the material characteristics into consideration like thickness, stretch rate, and stretch tensity.

Mechanical Stop

A mechanical stop is a physical stop or limiter on the press brake back gauge system, which is a terminology used in controlling the material position and ensuring accurate and consistent bending.

Minimum Inside Radius

The minimum inside radius is the minimum radius that can be achieved during the bending operation process. This will not result in acceptable material damage or deformation.

Neutral Axis

The neutral axis is the center axis or line, which keeps constant during bending. When it is stretched and compressed, it almost will not deform.

Outside Setback

Outside setback refers to the distance between the edge of the material and the bend line outside the bend. It ensures correct material position to achieve precise bending.

Pinch Point

The pinch point refers to the area between the upper and bottom beams, where the material will be squeezed during the bending. Keeping the finger and hand away from pinch points is of pivotal importance.

Stroke

Refers to the distance the ram travels during a bending operation, from its highest to lowest point. Stroke length: the maximum open size of the brake press i.e. the distance between the top of the lower beam and the bottom of the upper beam when the brake is fully open and there is no tooling installed. It determines the maximum bending depth that can be achieved.

Tonnage

This will be the maximum force that the press brake can exert on the workpiece. This measurement is critical for determining the machine’s capacity to bend specific materials and thicknesses.

To calculate the required tonnage, press brake operators must consider the material’s thickness, tensile strength, and the desired bend radius. For example, bending thicker steel requires more tonnage to avoid excessive deformation or even damage to the machine.

Swing up Finger

Back gauge fingers or stops can be swung upward and retracted, allowing larger or wider components that bend beyond the normal back gauge range.

Tandem

Two or more press brakes controlled by the same controller which are used to bend extremely large parts.

Tensile Strength

Tensile strength refers to the biggest stretch force that the material can be bent before broken or invalid. This is the factor to be considered when choosing the bending material.

Throat

Throat refers to the maximum depth distance ranging from the center line of the bottom beam to the frame. The depth of the press brake before the vertical supports limits flange length. It determines the biggest depth of the material that can be bent across its entire width. Most press brakes are only constrained by the throat of a brake around the driving cylinders.

Top Dead Center

The top dead center is the highest point arrived by the punch or upper beam of the press brake during the upper stroke. This is the position of the brake when it is fully closed into the die.