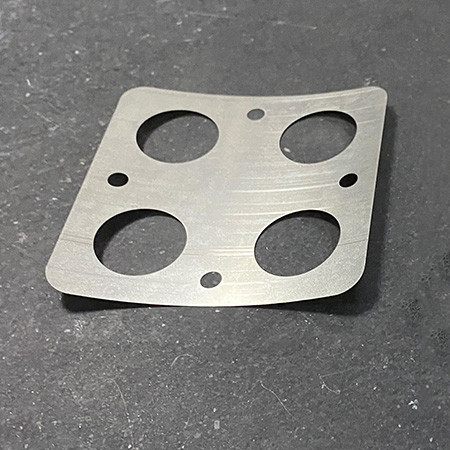

Automatic Leveling Adjustment: The four-point automatic gap adjustment system, driven by servo motors, ensures highly precise and uniform leveling of sheets, correcting warping or distortion without manual intervention. This feature minimizes human error and enhances consistency in production.

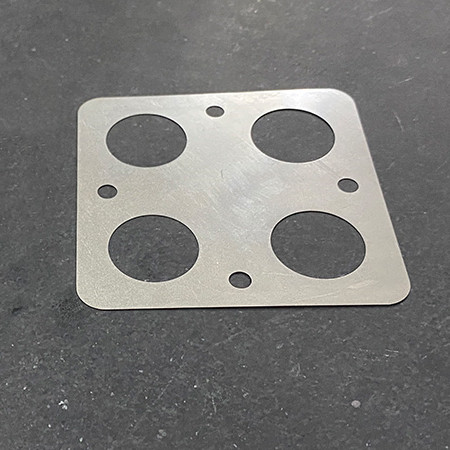

High Precision: The machine is equipped with 21 leveling rolls (10 upper, 11 lower), which work in tandem to effectively flatten and level metal parts, especially laser-cut, plasma-cut, and stamped components. This system ensures high-quality flatness and dimensional accuracy, which is critical for further processing like welding or bending.

Wide Processing Range: With a working width of 200-2200mm, the machine can handle a range of part sizes, from small to medium-sized sheets. The rated thickness range of 0.6 to 3mm makes this machine suitable for a variety of applications in industries like automotive, electronics, home appliances, and construction.

Efficient Production: Designed to increase throughput, the machine supports high-speed leveling, which helps reduce cycle times and increases overall productivity. This feature is essential in environments with high-volume production needs.

Precise Roll Control: The servo-controlled leveling roller gap adjustment ensures that the material is consistently leveled, even with varying thicknesses, providing uniformity and minimizing material waste.

Durability and Reliability: The robust construction of the machine, combined with precision-driven controls, ensures long-term durability and consistent performance in demanding environments. The automatic adjustments minimize downtime and the need for manual calibration, making this machine suitable for continuous operations.

These part leveling machines are ideal for industries that require precise leveling of light metal parts, including: