JT-D650/D850 High Precision Positioning Die Cutting Machine is designed for high-accuracy die cutting applications. It features precise positioning technology and is suitable for die-cutting tasks that demand stable pressure, accurate alignment, and reliable performance. This machine is commonly used in industries that require precision cuts, such as electronics, labels, films, and wood mold processing.

Key Performance Features:

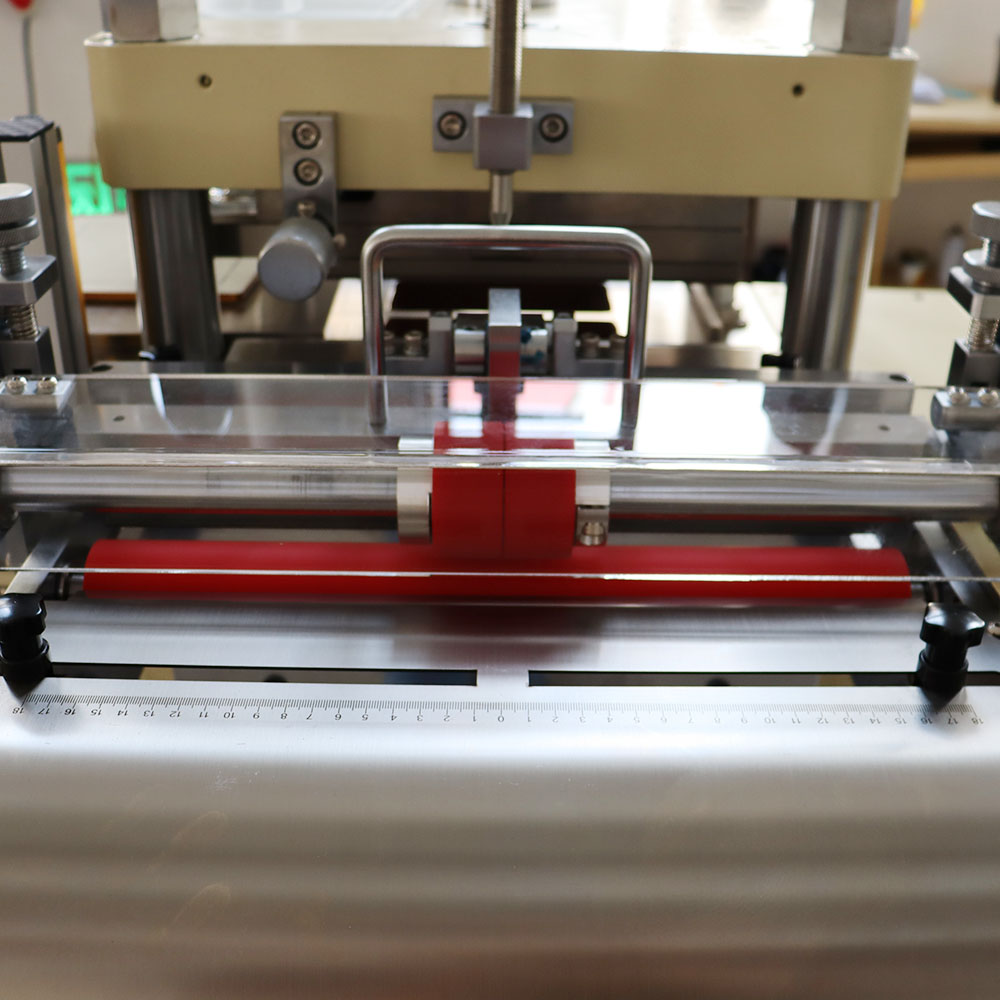

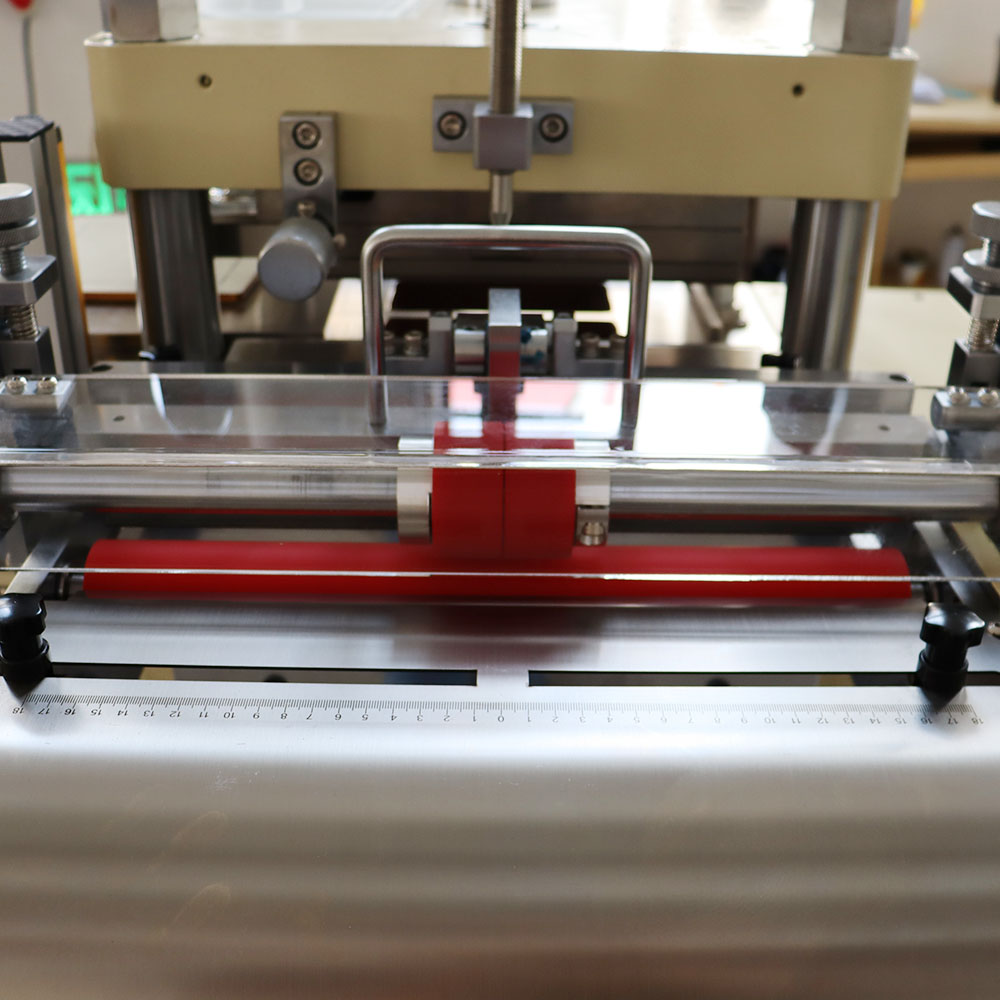

Small Hole Positioning System: Utilizes a small hole positioning instant correction device to ensure accurate alignment during the die-cutting process.

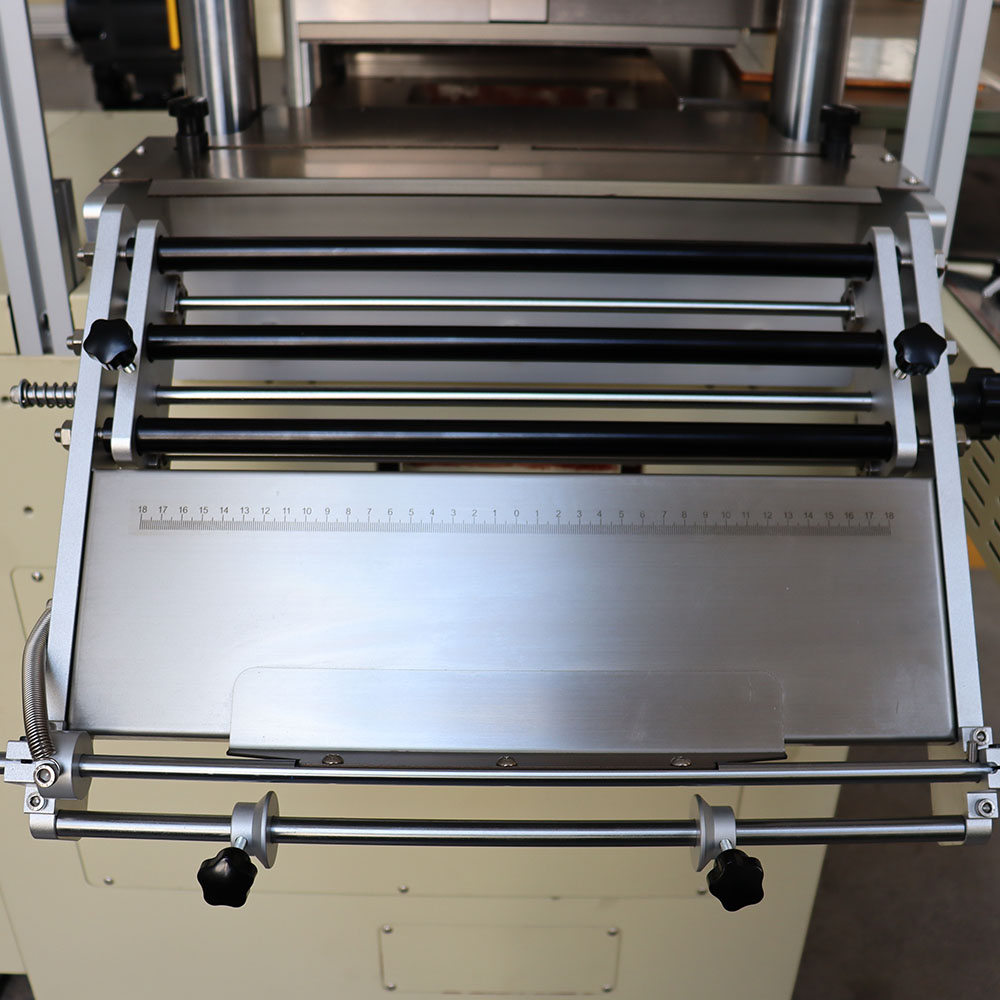

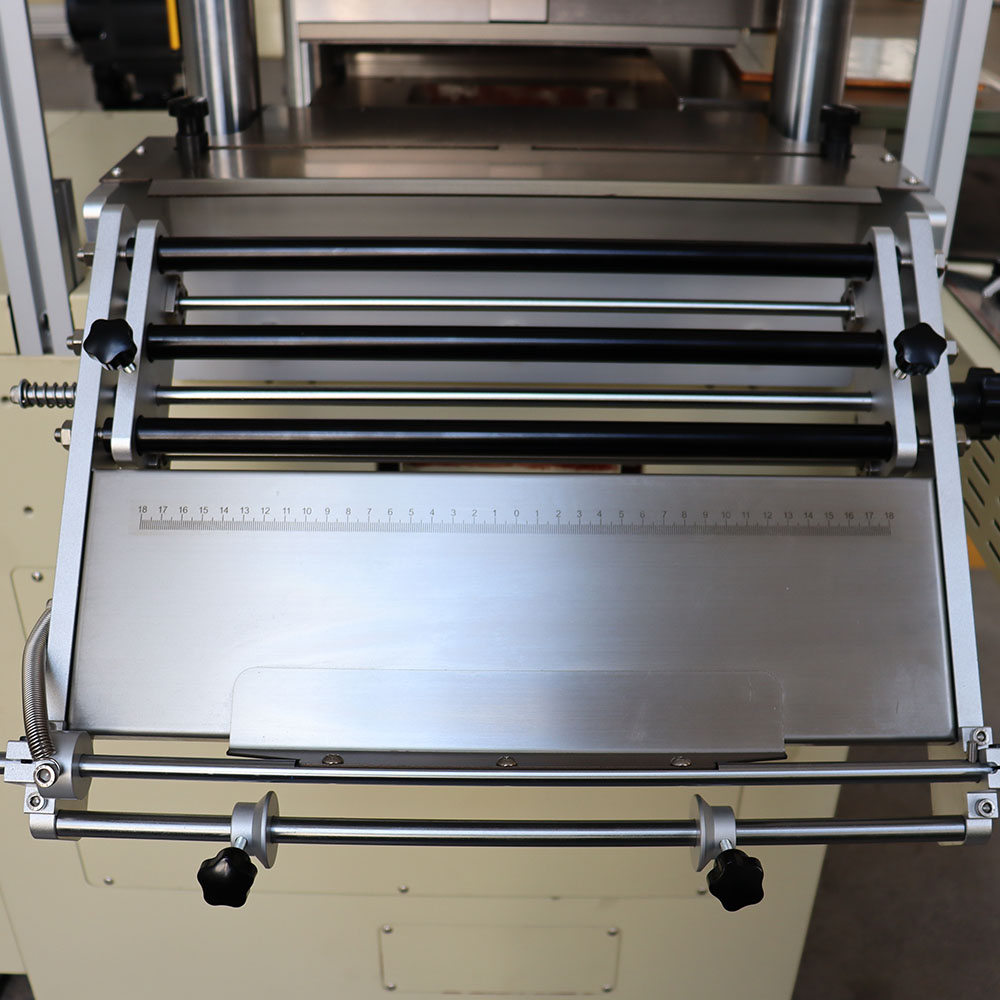

Double Servo Drive: Provides stable pressure with reduced noise for more precise drawing and cutting.

Digital Display: Electric digital display for easy and quick voltage adjustment, improving efficiency and user-friendliness.

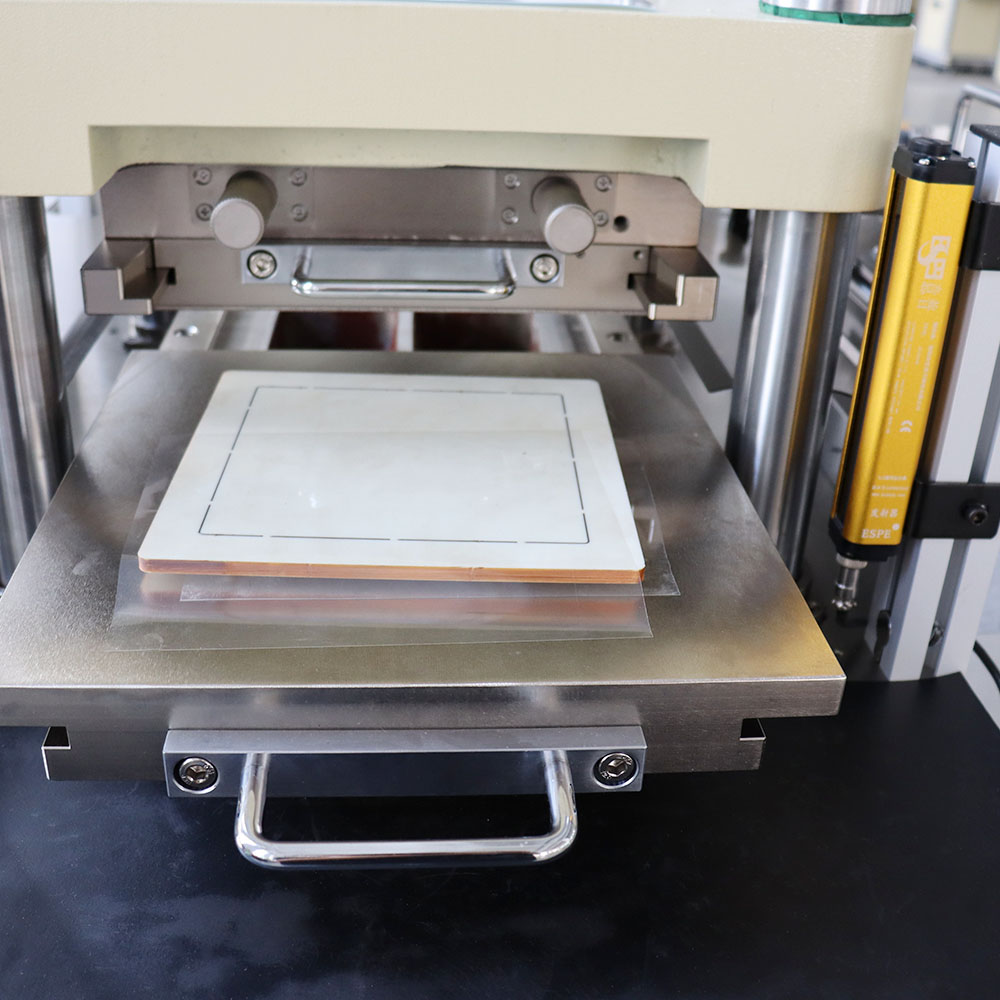

Powerful Punching Force: The machine is capable of exerting high punching force with consistent die-cutting pressure.

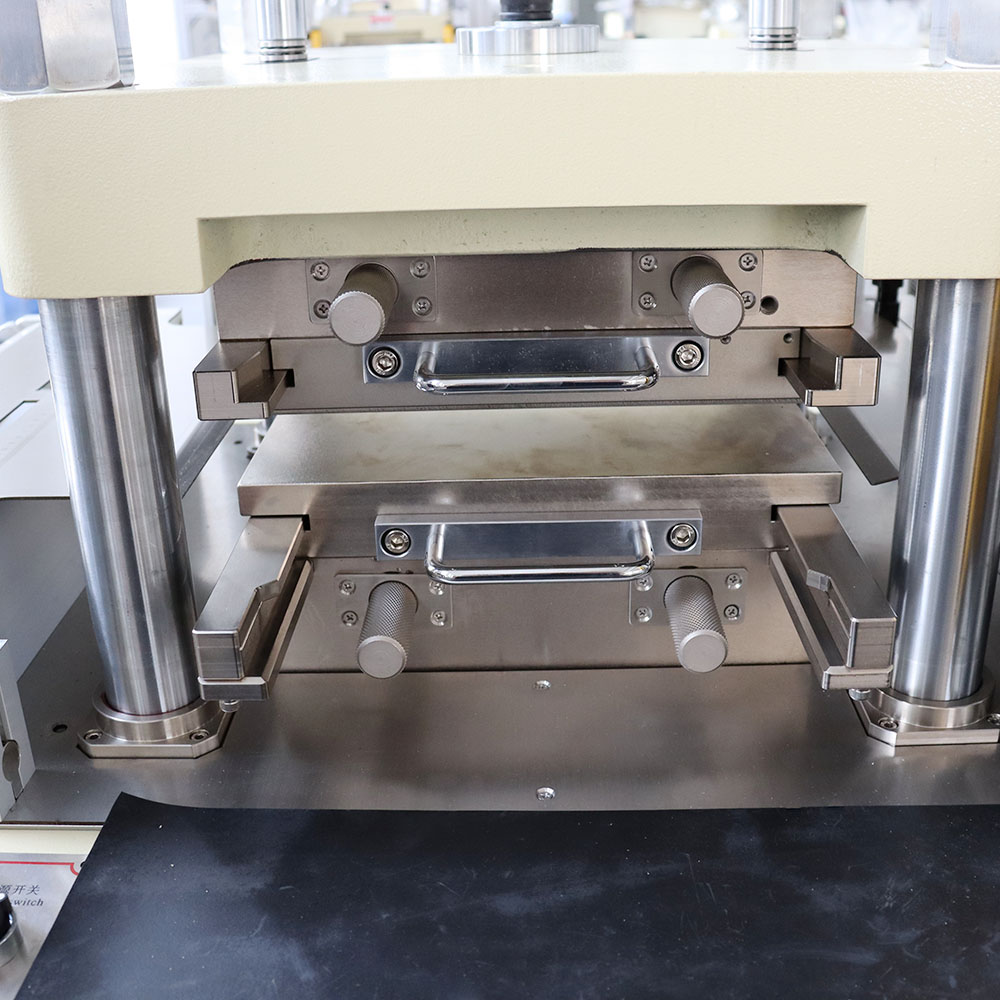

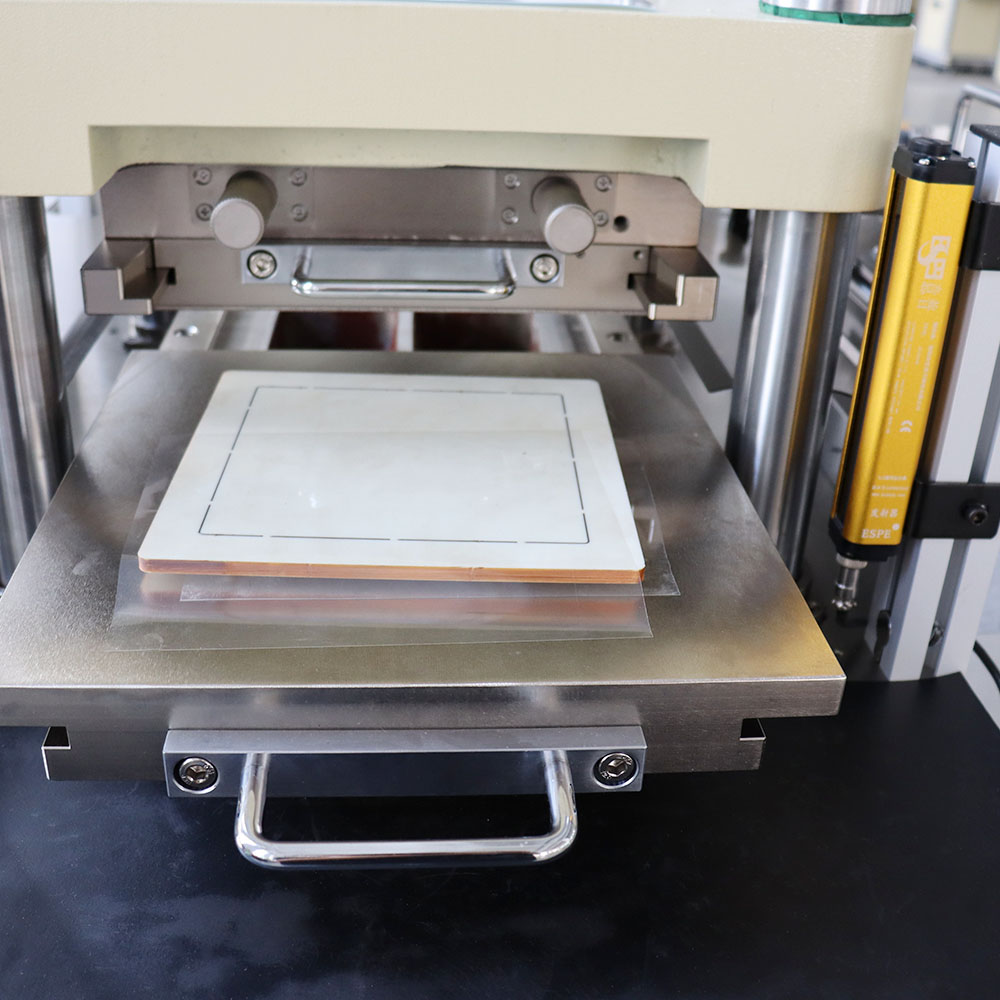

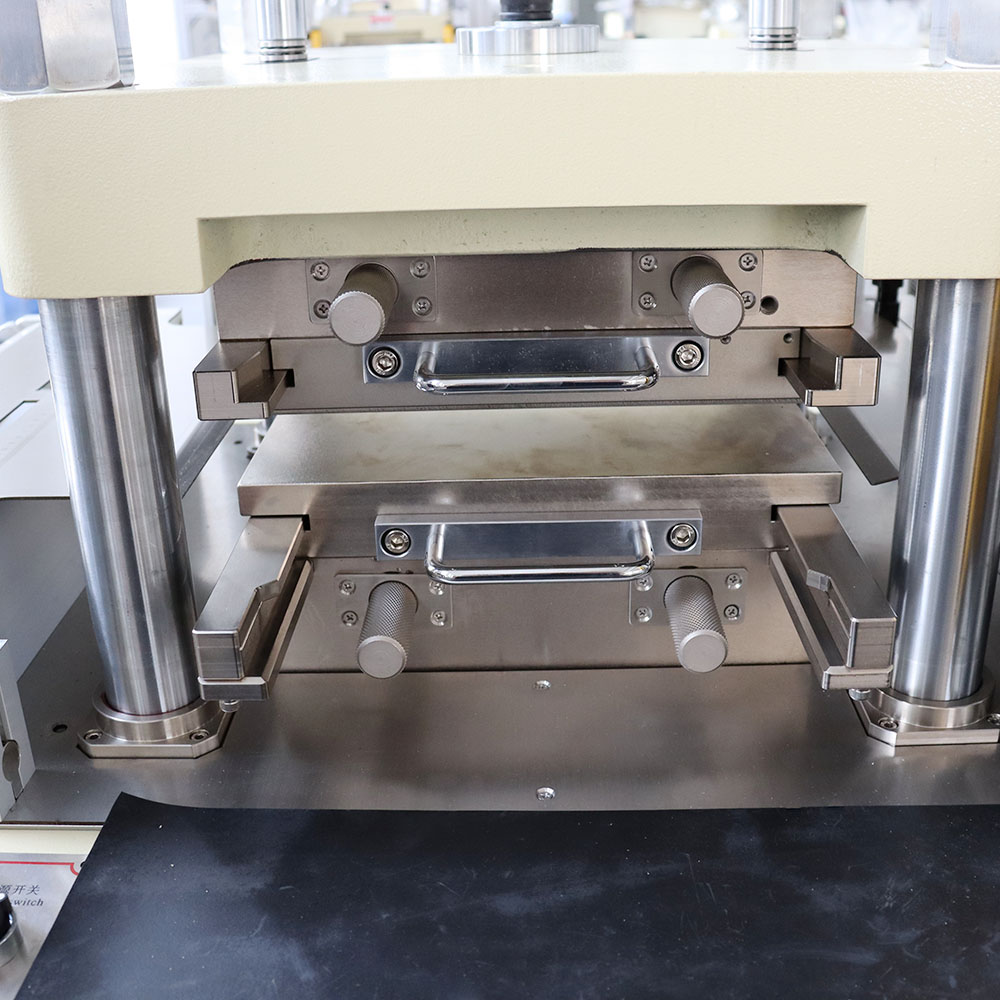

Quick Die Change (QDC) Mold: Equipped with a QDC mold system, enabling quick and multiple high-precision nesting die cuts, making it suitable for versatile production needs.

Technical Specifications:

| Specifications | JT-D650 | JT-D850 |

| Feed Width | 650 mm | 850 mm |

| Max. Die Cutting Area | 630 × 630 mm | 850 × 850 mm |

| Max. Operating Speed | 6000 punches/hour | 6000 punches/hour |

| Punching Stroke | 28 mm | 20 mm |

| Pressure Regulation | 10 mm | 10 mm |

| Voltage Regulation Accuracy | 0.005 mm | 0.005 mm |

| Drawing Accuracy | ±0.05 mm | ±0.05 mm |

| Upper Form Size | 650 × 650 × 20 mm | 860 × 860 × 18.5 mm |

| Lower Template Size | 650 × 650 × 40 mm | 860 × 860 × 18.5 mm |

| Overall Dimensions | 2250 × 1800 × 1700 mm | 2450 × 1850 × 1450 mm |

| Machine Weight | 4200 kg | 5500 kg |

| Air Source Specification | 0.5–0.7 MPa | 0.5–0.7 MPa |

| Total Power | 10.5 kW | 18 kW |

| Lubrication Mode | Intermittent fuel supply | Intermittent fuel supply |

| Applicable Die Types | Plywood mold, wood mold | Plywood mold, wood mold |

Performance Characteristics:

Small hole positioning instant correction device.

Double servo drive for stable pressure, low noise, and precise drawing.

Electric digital display for quick and convenient voltage adjustment.

High punching force with stable die-cutting pressure.

QDC mold allows multiple high precision nesting die cutting to be achievable.

Applications:

This machine is well-suited for industries that require precision die cutting for materials like plywood, wood, and other specialized molds. It is particularly useful in:

The JT-D650/D850 ensures high production efficiency, accurate results, and versatility for a wide range of die-cutting needs.