Insert Grinding Machine MK-400PLUS

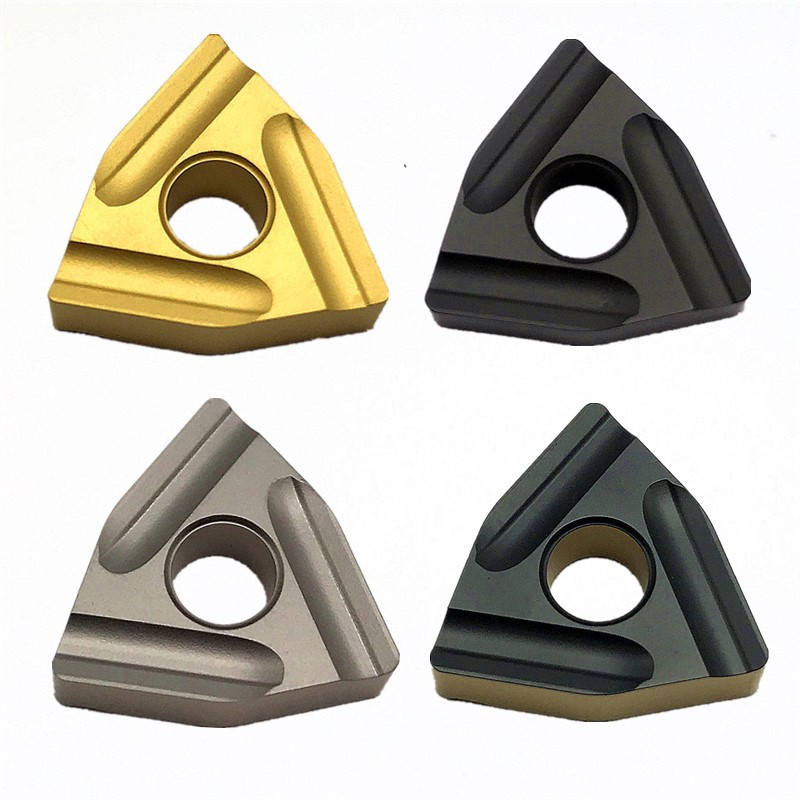

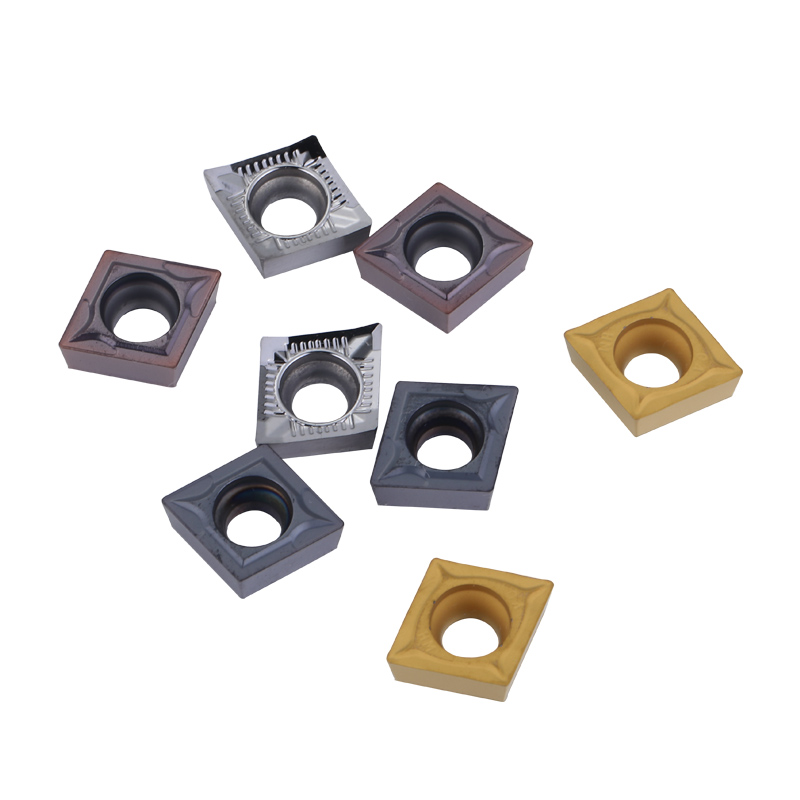

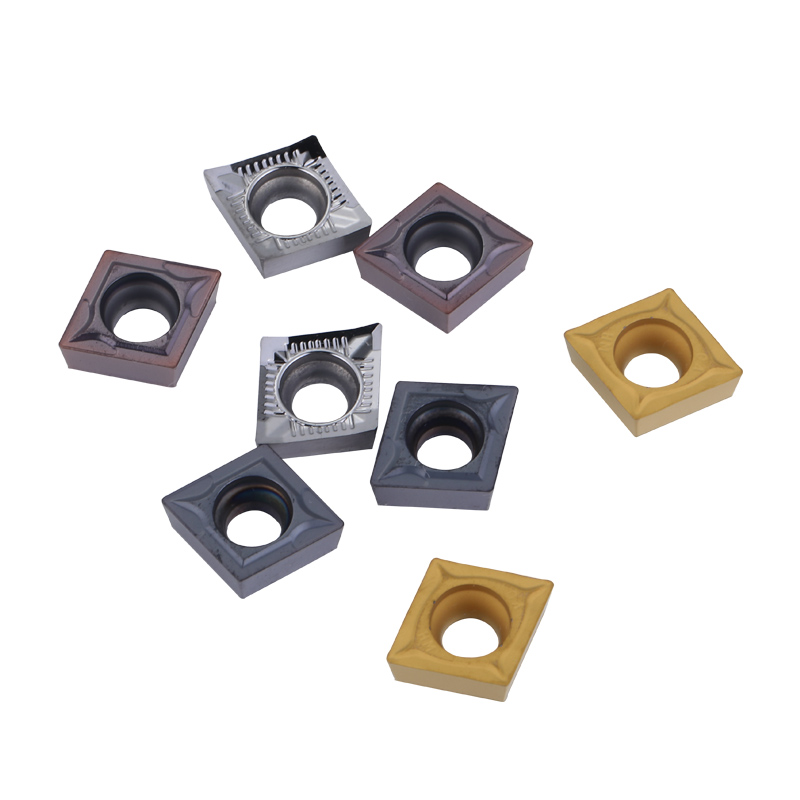

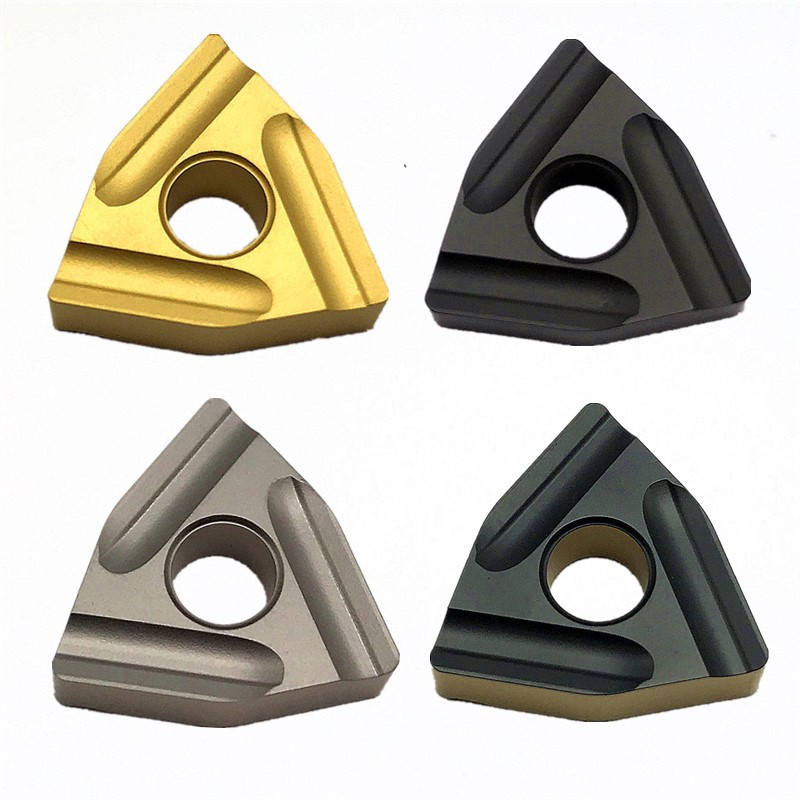

High-Precision CNC Insert Grinder for Carbide, Cermet, Ceramics, CBN & PCD Indexable Inserts

The MK-400PLUS is a high-precision CNC grinding machine specifically engineered for the efficient and repeatable production of indexable inserts made from ultra-hard materials, including carbide, cermet, ceramics, CBN, and PCD. Designed for maximum flexibility, performance, and accuracy, this model is ideal for both mass production and small-batch customized insert grinding.

Whether you're manufacturing standard ISO inserts or complex custom geometries, the MK-400PLUS ensures superior surface finish, excellent form accuracy, and reliable repeatability — making it an essential solution for cutting tool manufacturers and resharpening services.

Key Features

✅ Material Compatibility

Carbide (tungsten carbide)

Cermet (ceramic-metal composite)

Ceramics (e.g. aluminum oxide, silicon nitride)

CBN (Cubic Boron Nitride)

PCD (Polycrystalline Diamond)

✅ Advanced CNC Control

Equipped with a high-performance CNC control system for full-axis servo control.

Supports multi-axis grinding for complex profiles and clearance angles.

Intelligent programming interface for ISO-standard insert shapes (e.g., CNMG, SNMG, TNMG, WNMG, etc.)

✅ Grinding Capabilities

Periphery grinding

Top and bottom surface grinding

Clearance angle grinding

Radius, chamfer, and relief grinding

Custom-shaped insert grinding

✅ High Precision

Grinding accuracy: ≤ ±2μm

Surface roughness: Ra ≤ 0.2μm

Repeatability: ≤ 1μm

High-precision spindle system with dynamic balancing

✅ Automatic Clamping & Positioning

Modular fixtures for various insert types (round, square, triangle, rhombic, custom)

Pneumatic or hydraulic clamping systems

Optional auto-loading system for unmanned operation

Technical Specifications

| Item | MK-400PLUS |

| Max. insert size | 40 mm |

| Grinding wheel size | Ø 400 mm × 40 mm × Ø127 mm |

| Grinding spindle power | 7.5 kW / 10 HP |

| Spindle speed | Up to 6000 rpm (variable) |

| Axis configuration | X, Y, Z, A (rotary), B (optional) |

| Positioning accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Cooling system | High-efficiency water-based or oil-based coolant system |

| Machine weight | Approx. 3500 kg |

| Dimensions (L×W×H) | 2000 mm × 1800 mm × 1900 mm |

| Control system | Siemens / Fanuc CNC (customizable) |

Applications

Production of ISO-standard indexable inserts for turning, milling, and drilling.

Grinding of special-profile inserts for aerospace, mold, automotive, and energy industries.

Regrinding of used carbide and PCD tools to extend tool life.

Standard & Optional Features

| Standard | Optional |

| CNC control system | Automatic loading/unloading robot |

| High-precision linear guideways | In-process measurement and compensation |

| Enclosed splash guard with safety interlock | Wheel dressing system (rotary diamond) |

| Coolant filtration unit | 3D probe for geometry inspection |

| Workpiece clamping fixtures for standard shapes | Custom fixtures for special inserts |

Advantages

Flexible production: Easily switch between different insert types and geometries.

⏱️ Fast cycle times: High material removal rates with premium finish.

Precision grinding: Meets the strictest tool tolerance requirements.

Cost-efficient: Reduces tooling costs through regrinding and high-efficiency production.

Automation-ready: Ideal for lights-out production environments.

Conclusion

The MK-400PLUS Insert Grinding Machine is a powerful, precision-engineered solution designed to meet the evolving needs of indexable insert manufacturing. With its combination of advanced CNC control, robust construction, and adaptability to multiple hard materials, it is the ultimate tool for high-performance insert grinding in modern toolmaking.