1600mm Sheet Metal Deburring Machine

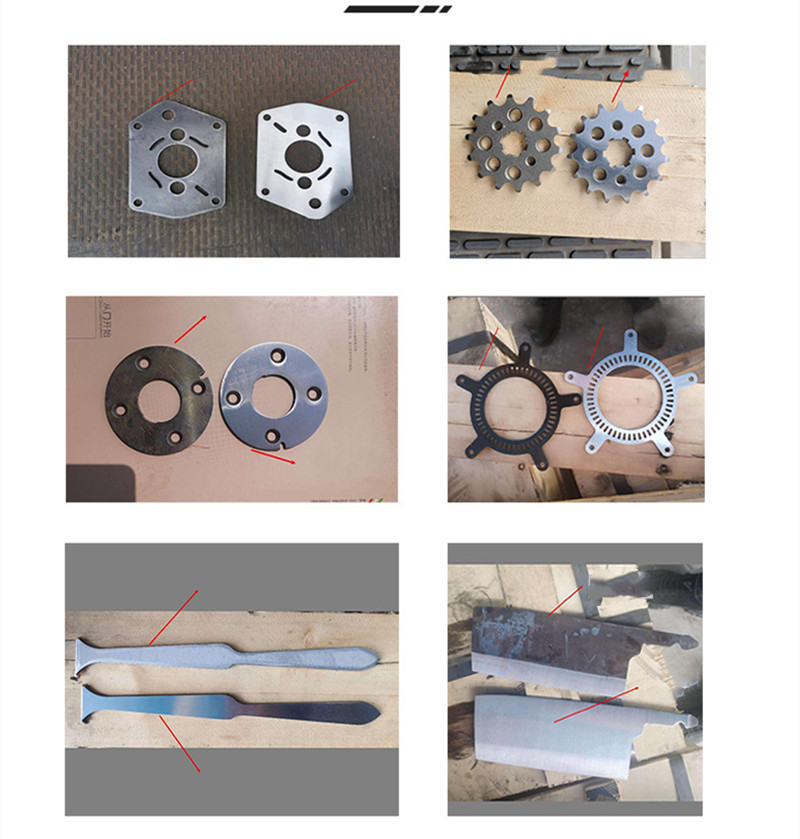

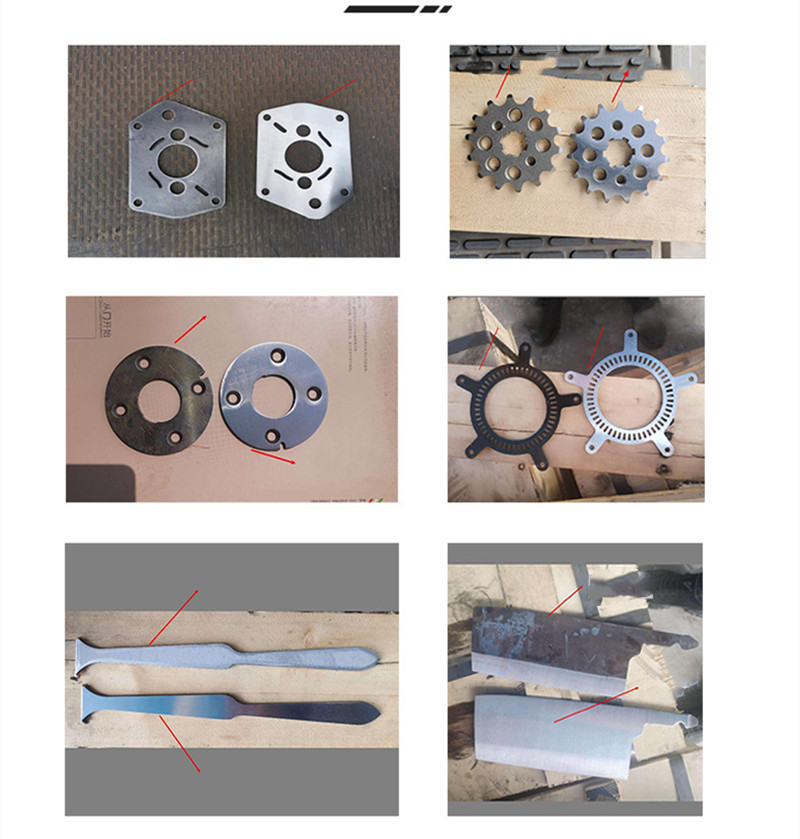

A 1600mm sheet metal deburring machine is specifically designed to efficiently process large metal sheets, providing high-quality surface finishing by removing sharp edges, burrs, and imperfections. This machine is ideal for various metal fabrication applications, including automotive, aerospace, and general manufacturing.

Technical Parameters of the Deburring Machine

| Parameter | Specification |

| Working Width | ≤ 1600 mm |

| Processing Thickness | 0.5 ~ 80 mm |

| Minimum Processing Size | 50 mm × 50 mm |

| Power of the Machine | 51.75 KW (including dust removal) |

| Sand Belt Size | Φ 1910 mm × 1600 mm |

| Sand Rolling Brush Size | Φ 300 mm × 400 mm |

| Delivery Speed | 0.5 ~ 6 m/min |

| Sand Belt Line Speed | 12 m/s |

| Rolling Brush Rotation Speed | Adjustable frequency conversion 500 ~ 1400 r/min |

| Rolling Brush Public Speed | 1 ~ 15 r/min |

| Number of Roller-Brush Planetary Revolution Shaft Heads | 1 |

| Number of Rolling-Brush Planetary Rotation Shaft Heads | 8 |

| Machined Thickness Servo Adjustment Precision | 0.01 mm |

| Rolling Brush Compensation Servo Adjustment Precision | 0.01 mm |

| Grinding Consumables | Sand belt + rolling brush |

| Dust Air Volume | 5000 m³/h |

| Contour Size of the Unit | Length 3250 mm × Width 2600 mm × Height 2150 mm |

| Weight of the Whole Machine | About 5.5 T |

Wide Processing Capability:

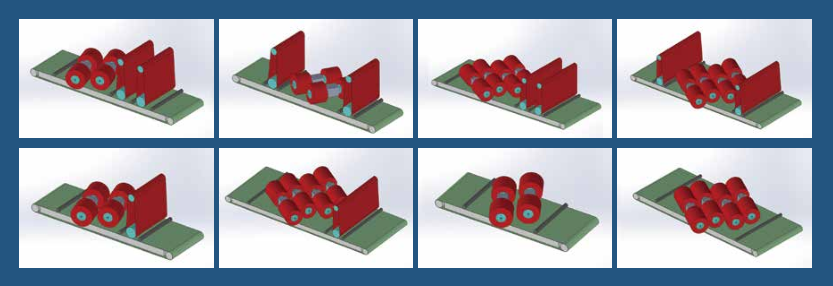

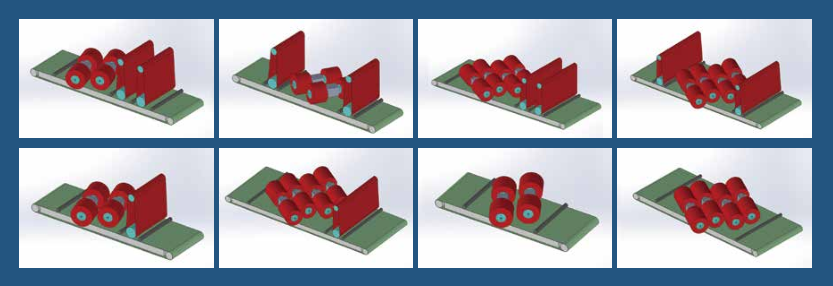

Versatile Deburring Options:

Equipped with multiple heads, such as abrasive belts, brushes, and polishing wheels, to handle different deburring tasks, including edge rounding, surface smoothing, and oxide removal.

High Precision and Efficiency:

Advanced Control Systems:

Robust Construction:

Dust Extraction System:

Safety Features:

Energy Efficient:

Applications: