Picosecond Laser Cutting and CO2 Laser Splitting

Picosecond Laser Cutting and CO2 Laser Splitting are two distinct but complementary laser technologies used in the precision processing of fragile materials like glass, sapphire, and ceramics. These methods offer advantages in terms of cutting accuracy, minimal heat impact, and efficiency, particularly for materials that are prone to cracking or chipping.

Picosecond Laser Cutting:

Picosecond lasers operate at extremely short pulse durations—typically in the range of one trillionth of a second (10⁻¹² seconds). This ultra-short pulse duration minimizes heat generation, making them ideal for cutting brittle materials like glass, sapphire, and ceramics with precision and minimal thermal damage.

Applications:

Optical components (cutting lenses, optical fibers)

Sapphire glass for smartphones, cameras, and high-end optics

Thin glass panels for electronics, such as touchscreens or displays

Semiconductor manufacturing (e.g., cutting silicon wafers or other brittle materials)

CO2 Laser Splitting:

CO2 lasers are a widely used laser technology that operates in the infrared spectrum (typically around 10.6μm wavelength) and can generate high power to achieve precise splitting or scoring of brittle materials. Unlike cutting, splitting focuses on applying heat to induce a controlled crack along a predefined line, allowing the material to break or separate cleanly.

Applications:

Glass splitting for smartphone covers, displays, and windows.

Sapphire splitting for camera lenses and high-precision optical windows.

Ceramic and hard materials splitting in industries like aerospace and automotive.

Optical glass and lenses used in high-precision optics and laser systems.

Laser Cutting and Splitting Integrated Machine

The Laser Cutting and Splitting Integrated Machine combines picosecond laser cutting, CO2 laser splitting, and automatic loading and unloading systems. It utilizes a picosecond laser beam focused by a laser fiber cutting head for precise cutting, while the CO2 laser heats the cut line, allowing the material to rapidly separate from the waste through thermal expansion and contraction.

Key Features:

High Precision and Clean Cuts:

Minimal edge chipping and no taper.

Low heat impact, with almost no dust or debris, resulting in excellent processing quality.

Stable Picosecond Laser Quality:

High-Speed and High-Precision Linear Motor:

Automated Loading and Unloading:

Applications:

This equipment is suitable for cutting transparent and brittle materials, such as:

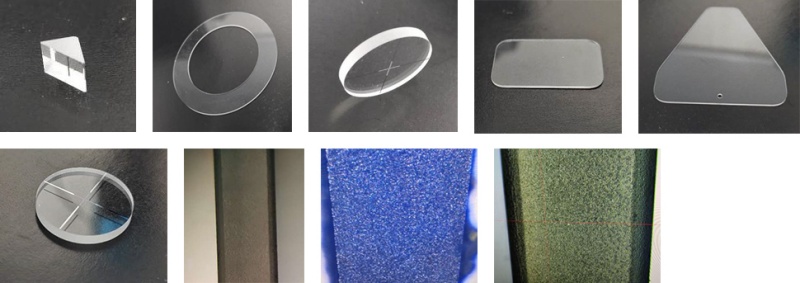

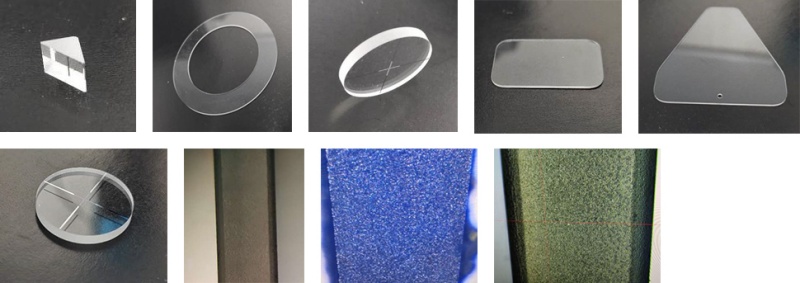

Sample Display:

The machine is capable of producing high-quality cuts on various materials, with precision and minimal waste.

Machine Specifications:

| Item | Technical Specifications |

| Model | C Series |

| Laser Power | 20W / 30W / 60W |

| Laser Wavelength | Infrared / Green / Ultraviolet (Optional) |

| Pulse Width | Nanosecond / Picosecond / Femtosecond (Optional) |

| Laser Lifetime | ≥ 20,000 hours |

| Repeat Position Accuracy | ≤ ±2μm |

| Minimum Line Width | 20μm |

| Edge Chipping | < 5μm |

| Maximum Platform Speed | 1200mm/s |

| Maximum Platform Acceleration | 12000mm/s |

| Control System Software | Laser Studio 8 (Integrated Vision, Laser, and Motion) |

| Supported File Formats | DXF, Gerber, G-code, etc. |

| Environmental Requirements | Temperature 22°C~25°C, Humidity < 55% |

| Power Requirements | 380V / 50Hz / ~6KVA |