Processing advantages of laser marking machine in bathroom industry

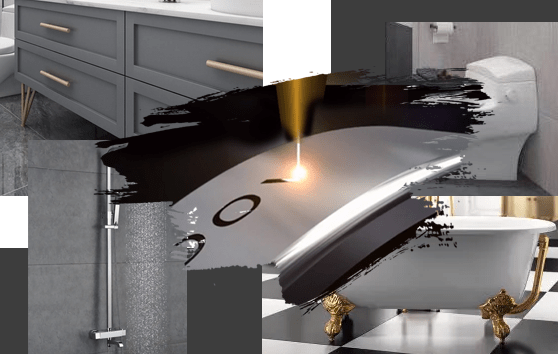

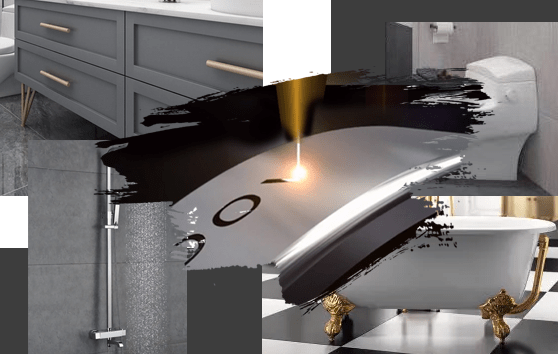

Bathroom is an important symbol of the evolution of human civilization and healthy lifestyle. The products in the bathroom industry usually refer to: bathroom cabinets, faucet showers, toilets, bathroom equipment, washbasins, flush valves, bathtubs and other bathroom accessories. The materials generally include ceramics, plastics, metal etc.

I believe that many of my friends have heard that they were injured in the news because of the explosion of the bathroom door and toilet. Most of these products have quality problems because they do not have 3C certification, or "copycat" products.

Therefore, in order to combat counterfeit and shoddy products, at the same time enhance the brand image, safeguard the interests of enterprises and consumers, it is very necessary to establish an effective product traceability system for bathroom products.

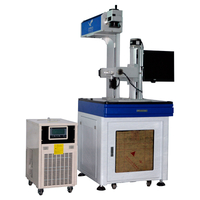

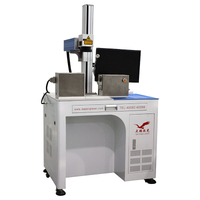

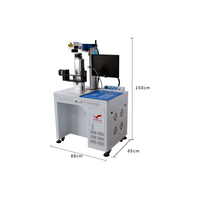

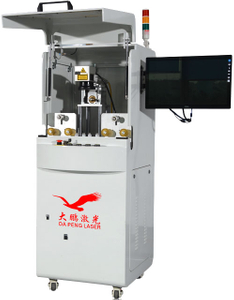

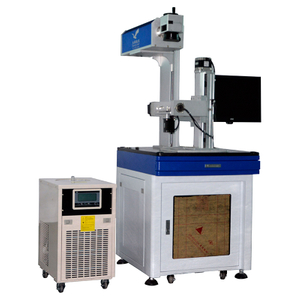

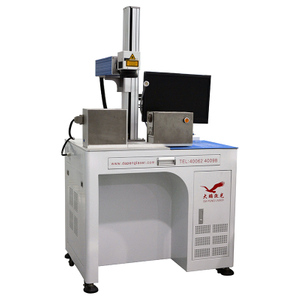

The laser marking machine can adapt to the high-quality marking requirements of these materials, solve the problem of marking quality, and provide an important guarantee for effective product traceability.

What are the processing advantages of laser marking machines in the bathroom industry? Chuke Intelligence invites everyone to learn together:

1. Good permanence: Laser marking uses a high-energy-density laser beam to partially irradiate the workpiece to vaporize the bathroom material or change its color, thereby leaving a permanent mark;

2. Strong flexibility: we can use software drawing to quickly draw and generate various text, graphics, characters, etc., to ensure that the pattern is clear and beautiful;

3. Simple operation: After debugging in the early stage, the operator can operate the machine after simple training;

4. Wide applicability: stainless steel, aluminum-magnesium alloy, zinc alloy, copper, plastic, pig iron, non-nickel-plated, galvanized, alumina and other materials can be finely marked;

5. Safety and environmental protection: laser marking will not produce toxic gas during the operation, so it is not harmful to the human body.