✅ RRR5340C Automatic Wet Wide Belt Sander | Magnetic Conveyor Table | 3 Sanding Heads | PLC Touch Screen

Product Overview:

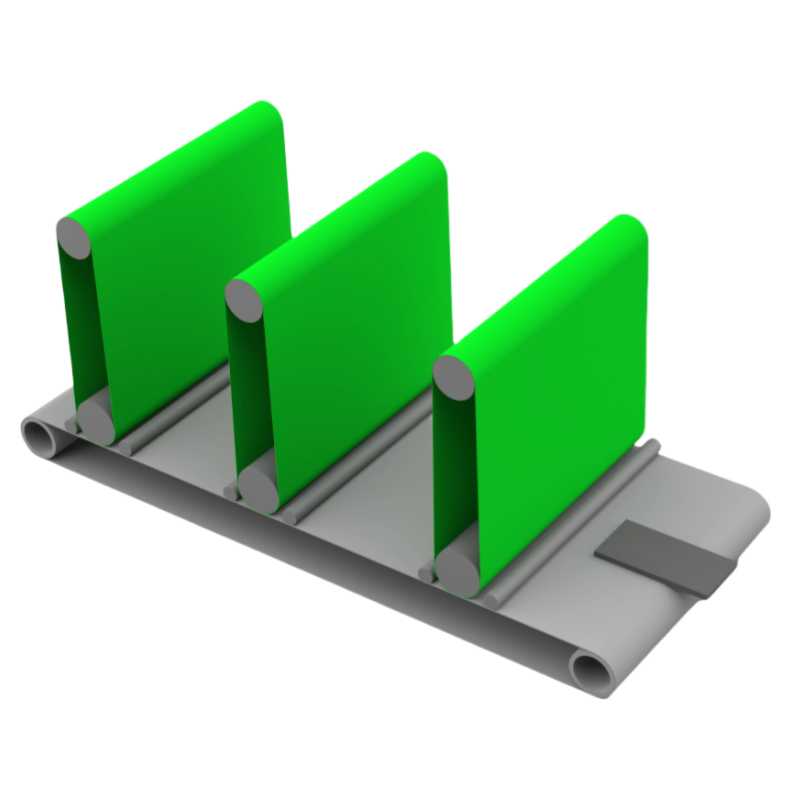

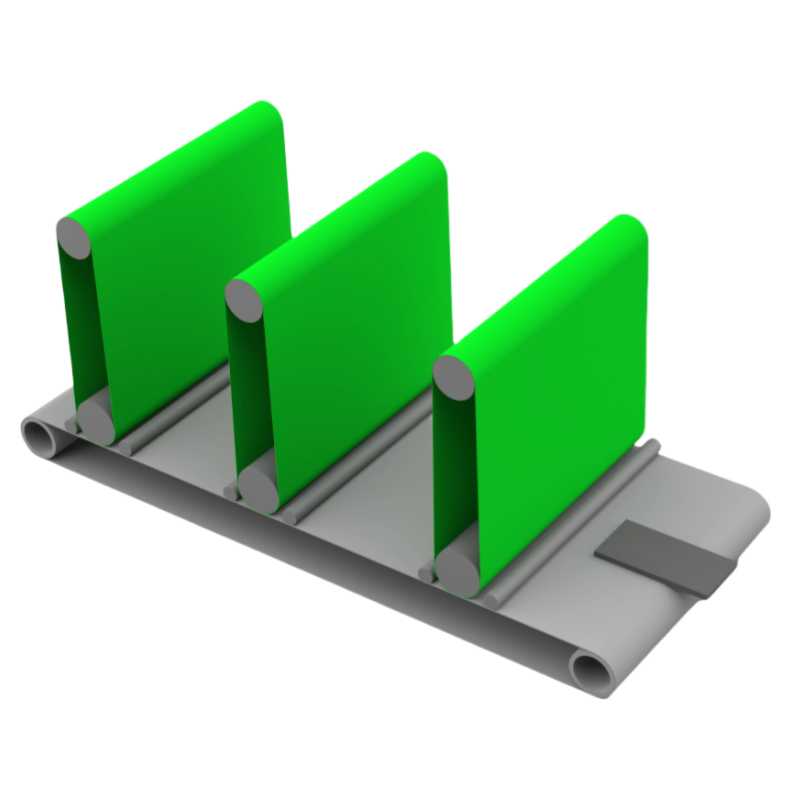

The RRR5340C Automatic Wet Wide Belt Sander is a versatile industrial-grade sanding machine designed to handle deburring, slag removal, oxide layer removal, edge rounding, and surface finishing of a wide variety of metal sheets and parts. Equipped with three sanding heads, a 400mm working width, and an integrated water cooling system, it ensures the highest quality surface treatment with minimal heat distortion and extended abrasive belt life.

The Magnetic Conveyor Worktable is ideal for securely holding down small ferrous parts during processing, minimizing part slippage and ensuring consistent, safe operation. The advanced PLC Touch Screen Control System offers intuitive operation, quick setup changes, and real-time monitoring of production data.

Designed for continuous industrial use, the RRR5240C Wet Wide Belt Sander delivers outstanding operational efficiency and reliable performance in metalworking, laser cutting, plasma cutting, stamping, and fabrication industries.

✅ Key Features:

✅ 3 Heavy-Duty Sanding Heads: Multi-stage processing in a single pass for optimal productivity.

✅ Wet Processing System: Water cooling reduces heat generation, eliminates dust, and prolongs abrasive life.

✅ Magnetic Conveyor Table: Stabilizes small metal parts during sanding, improving finish quality and safety.

✅ PLC Touch Screen Interface: Easy-to-use smart controls for parameter settings, fault alarms, and maintenance prompts.

✅ 400mm Working Width: Compact footprint with robust capability, ideal for small-to-medium-sized sheet metal parts.

✅ Edge Rounding and Surface Finishing: Achieve smooth, burr-free edges and uniform surface grain.

✅ Durable Structure: Industrial-grade frame ensures vibration-free, long-lasting performance.

✅ Adjustable Feed Rate: Customizable feed speed to suit different material types and finishing demands.

✅ Low Maintenance: Designed for easy consumable replacement and minimal service interruptions.

✅ Optional Customization: Tailor machine configuration to suit specific production lines.

✅ Main Functions:

✅ Slag and Dross Removal: Removes heavy slag from plasma or flame-cut steel.

✅ Deburring: Effectively eliminates sharp edges and burrs on laser-cut, punched, or sheared parts.

✅ Oxide Removal: Cleans oxide layers ensuring improved weldability and coating adhesion.

✅ Edge Rounding: Creates uniform rounded edges to prevent paint peeling and enhance safety.

✅ Fine Surface Finishing: Achieves satin, brushed, or hairline finishes on stainless steel and other metals.

✅ Graining: Produces straight grain patterns for decorative metal finishes.

✅ Technical Specifications:

| Specification | RRR5240C |

| Max Working Width | 400 mm |

| Max Working Thickness | 60 mm |

| Min Working Length | 150 mm |

| Sanding Stations | 3 (Abrasive Belt Heads) |

| Sanding Belt Size | 1900 mm × 400 mm |

| First Sanding Head Power | 7.5 kW |

| Second Sanding Head Power | 7.5 kW |

| Third Sanding Head Power | 7.5 kW |

| Conveyor Motor Power | 1.5 kW |

| Lifting Motor Power | 0.37 kW |

| Total Power Consumption | ~24 kW |

| Conveyor Speed | 0.5 – 6 m/min adjustable |

| Sanding Belt Speed | 12 m/s |

| Cooling System | Water circulation with filtration |

| Control System | PLC Touch Screen |

| Conveyor Type | Magnetic Worktable |

| Machine Dimensions (L×W×H) | 2600 × 1500 × 1900 mm |

| Machine Weight | ~2200 kg |

✅ Typical Applications:

✅ Metal sheet deburring after laser/plasma cutting

✅ Removal of dross/slag from flame-cut parts

✅ Oxide layer cleaning before welding or coating

✅ Small parts edge rounding with magnetic fixation

✅ Hairline finishing for stainless steel kitchenware

✅ Decorative grain finish for architectural metal panels

✅ Pre-paint surface preparation

✅ Elevator panels, appliances, and sanitaryware surface treatment

✅ Automotive parts deburring and finishing

✅ Application Industries:

Metal Fabrication Shops

Laser Cutting Centers

Plasma and Oxy-Fuel Cutting Factories

Kitchenware and Home Appliance Manufacturers

Elevator and Decorative Panel Producers

Automotive Component Suppliers

General Sheet Metal Workshops

✅ Advantages of RRR5340C:

✅ Higher Efficiency: Triple sanding heads complete deburring, edge rounding, and finishing in one pass.

✅ Lower Consumable Costs: Water cooling extends the life of sanding belts.

✅ Operator-Friendly: PLC screen simplifies operation with quick recipe changes.

✅ Space Saving: Compact machine suitable for workshops with limited space.

✅ Environmentally Safer: Wet sanding process reduces airborne dust.

✅ Versatile Applications: One machine serves multiple functions and materials.

✅ Summary:

The RRR5340C Wet Wide Belt Sander offers superior metal finishing capabilities, optimized for small part processing, laser cut edge deburring, and fine surface treatments. The magnetic conveyor worktable ensures precision even on the smallest components, while the PLC control system guarantees easy operation and consistent results. Whether you need to deburr, round edges, or create a decorative finish, the RRR5240C delivers industrial-grade reliability and quality output.