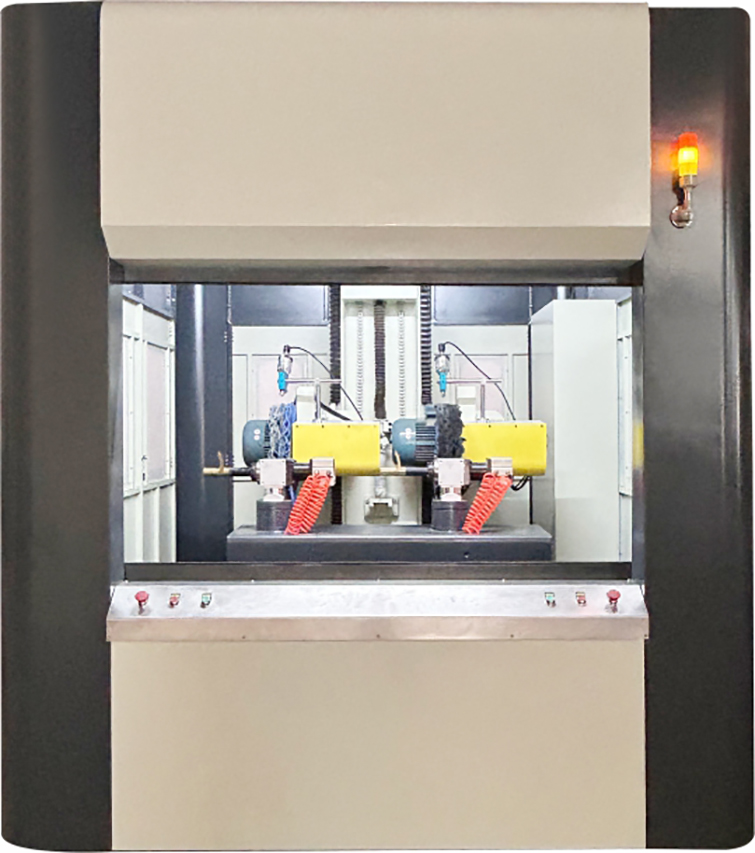

CNC Polishing Machine for Kitchen Handles and Furniture Parts: High-Quality Mirror Finishing (Dual-Station Polishing Machine)

Overview:

A CNC Polishing Machine designed to polish kitchen handles and furniture parts, providing a high-quality mirror finish. This dual-station machine enables simultaneous polishing of multiple parts, maximizing efficiency while maintaining superior consistency and surface quality. Ideal for manufacturers requiring precision and productivity in polishing metal components.

Universal CNC Machine for Polishing and Brightening Brass Casted Faucets, Zamak Levers, Zamak Faucets, Shower Heads, and Any Sanitary Ware

Key Features and Functions

Multi-Material Compatibility:

Suitable for polishing and brightening brass, Zamak, and other metals commonly used in sanitary ware.

Handles various shapes and sizes, including faucets, levers, shower heads, and similar items.

Precision Polishing:

Achieves uniform surface finishing with consistent quality across complex geometries.

Capable of fine polishing to create a bright, mirror-like finish.

Customizable Programs:

CNC system allows precise control over polishing speed, pressure, and movement patterns.

Pre-programmed paths tailored to specific products to minimize material loss and ensure optimal finishing.

High Efficiency:

Environmentally Friendly Design:

User-Friendly Interface:

Implementation Process

Setup and Fixture Design:

CNC Programming:

Create or load CNC polishing programs tailored to the product geometry and desired finish.

Adjust parameters such as tool speed, rotation angles, and pressure for material type and finish level.

Tool Selection and Calibration:

Choose appropriate polishing tools, such as abrasive belts, buffing wheels, or diamond-coated pads.

Calibrate the machine to ensure uniform polishing and consistent results.

Automated Polishing Process:

The CNC machine executes the pre-programmed polishing cycle.

Multi-axis movement ensures all surfaces, including intricate curves and edges, are polished evenly.

Brightening and Finishing:

Quality Inspection:

Inspected for uniformity, brightness, and smoothness to meet quality standards.

Adjustments are made to the CNC program if necessary for improved performance.

Packaging and Delivery: