✅ RR5240 400mm Wet Wide Belt Sander – Product Overview

Product Introduction: RR5240 400mm Wide Belt Metal Finishing Machine

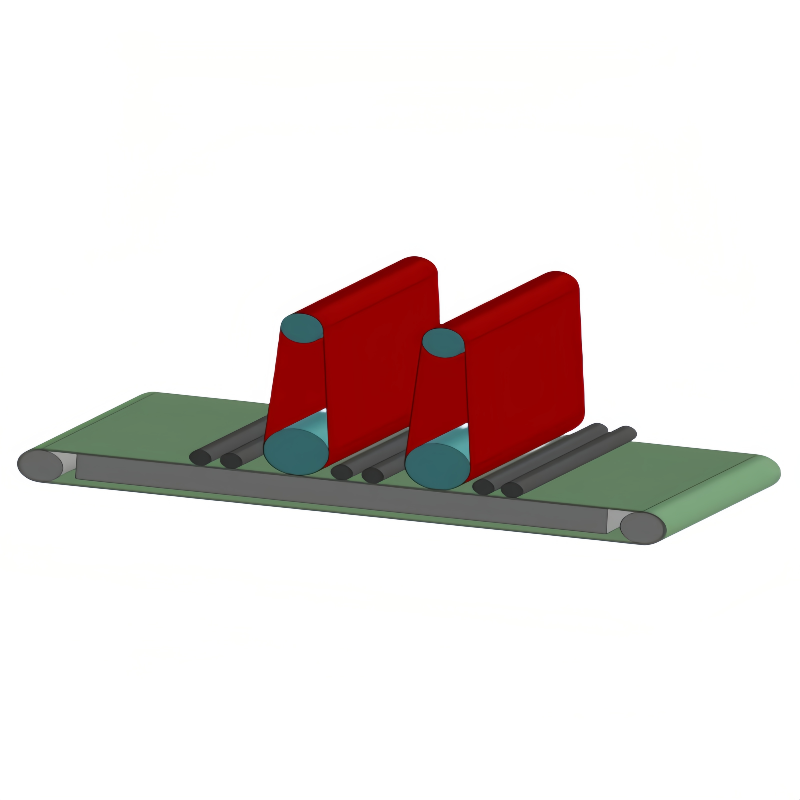

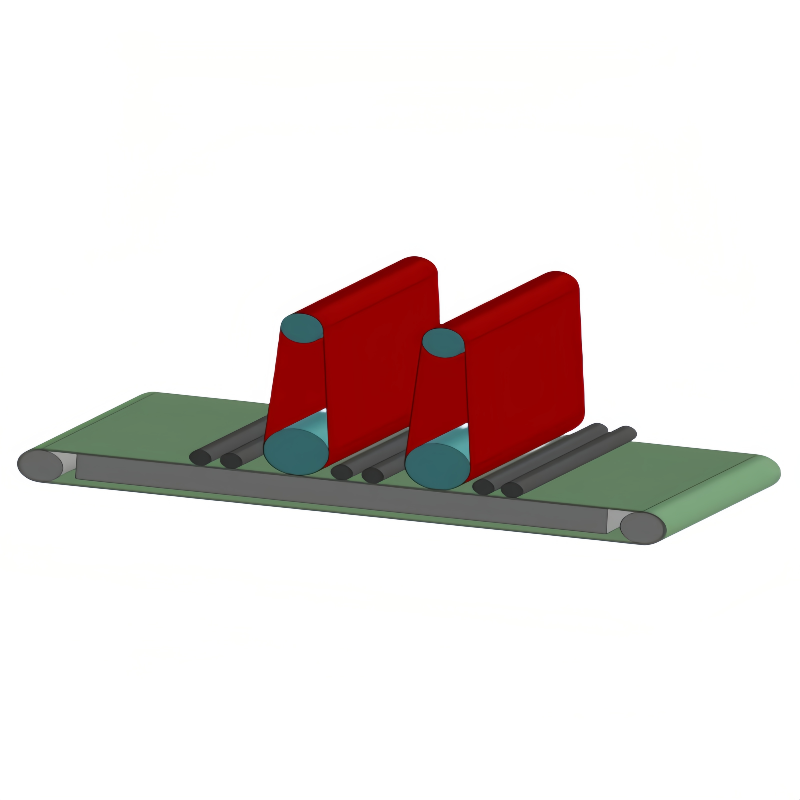

The Model RR5240 is a heavy-duty, dual-head, wide-belt sanding machine engineered specifically for high-performance wet grinding, deburring, and finishing of metal sheets, with a primary focus on stainless steel. It is an ideal solution for post-processing laser-cut, plasma-cut, or punched parts, efficiently removing heat discoloration (heat tint), burrs, and surface imperfections to produce a uniform, high-quality satin finish.

Key Features & Advantages

Dual Sanding Head System: Equipped with two independent 7.5 kW sanding heads, this machine offers exceptional power and flexibility. The heads can be used sequentially for a two-stage process (e.g., coarse then fine finishing) or configured for different operations, significantly enhancing productivity and finish quality in a single pass.

Superior Stainless Steel Finishing: Specifically designed for water-cooled operation, it is perfect for finishing stainless steel. The water system prevents overheating, which avoids altering the metal's properties and ensures a consistent, scratch-free satin finish without the "orange peel" effect.

Efficient Deburring: Excellently removes sharp burrs and edges left by laser cutting, plasma cutting, or other machining processes, preparing parts for safe handling and further fabrication.

Wet Process Technology: The integrated water circulation and filtration system suppresses dust completely, eliminates the risk of combustion, and provides constant cooling for both the workpiece and the abrasive belt. This extends belt life, improves finish quality, and maintains a clean working environment.

Robust Construction: With a weight of approximately 1800 kg, the machine is built for stability, vibration reduction, and long-term durability in industrial environments.

Minimal External Dust Extraction: The water bath filtration system traps nearly all particulates within the machine, drastically reducing the need for and cost of external dust collection systems.

Technical Specifications

| Parameter | Specification |

| Model | RR5240 |

| Max Working Width | 400 mm |

| Max Working Height (Thickness) | 60 mm |

| Min Working Length | 150 mm |

| Number of Sanding Heads | 2 |

| Sanding Belt Size | 1900 mm × 400 mm |

| Motor Power per Head | 7.5 kW |

| Total Installed Power | ~17 kW |

| Feeding Speed (Variable) | 0.5 – 6 m/min |

| Abrasive Belt Speed | ~12 m/s |

| Cooling System | Full water circulation with integrated filters |

| Worktable Type | Standard conveyor belt; Optional magnetic table for enhanced hold-down of ferrous materials |

| Dust Collection | Internal water bath filtration |

| Machine Dimensions (L×W×H) | 2400 mm × 1450 mm × 1800 mm |

| Machine Weight | ~1800 kg |

Applications

This machine is primarily used for:

Deburring: Removing sharp edges from laser-cut, plasma-cut, and punched parts.

Descaling/Removing Heat Tint: Eliminating the heat-affected zone (HAZ) and discoloration from thermal cutting processes on stainless steel.

Surface Finishing: Creating uniform satin, brushed, or hairline finishes on stainless steel, aluminum, and other metals.

Surface Leveling: Smoothing out minor imperfections and waviness on sheet metal.

Ideal For Industries:

Metal fabrication shops

Laser cutting service providers

Kitchen equipment manufacturing

Architectural metalwork (e.g., elevator panels, signage)

Automotive and aerospace component finishing

Summary

The RR5240 Wide Belt Finisher is a powerful, efficient, and purpose-built machine for demanding metal finishing applications. Its dual-head design, powerful motors, and advanced wet processing system make it a superior choice for achieving perfect deburred and finished results on stainless steel and other metals, while ensuring a safe and clean operational environment. The optional magnetic bed further enhances its capability for processing a wide variety of ferrous parts