100T 2500mm CNC Hydraulic Double Servo Press Brake – CNC Hybrid Press Brake Sheet Metal Bending Machine

The 100T 2500mm CNC Hydraulic Double Servo Press Brake is a state-of-the-art sheet metal bending machine that combines advanced CNC control with a hybrid hydraulic-servo system to provide high performance, energy efficiency, and precision. This machine is specifically designed for bending sheet metal in industries that require high-quality forming operations, including automotive, aerospace, metal fabrication, and heavy machinery manufacturing.

This press brake features a bending force of 100 tons and a bending length of 2500 mm, making it suitable for bending medium to large-sized sheets of steel, aluminum, stainless steel, and other materials. The CNC Hybrid Press Brake ensures precise control over the bending process, offering enhanced automation, repeatability, and a reduction in material waste.

Double Servo Electro-Hydraulic Hybrid Press Brake parameters:

| Parameter Name | Unit | WBL-40/1500 | WBL-100/2500 | WBL-100/3200 | WBL-100/4100 | WBL-160/3200 | WBL-160/4100 | WBL-200/3200 | WBL-200/4100 |

| Bending Force | kN | 400 | 1000 | 1000 | 1000 | 1600 | 1600 | 2000 | 2000 |

| Effective Bending Length | mm | 1500 | 2500 | 3200 | 4100 | 3200 | 4100 | 3200 | 4100 |

| Maximum Opening Height | mm | 400 | 460 | 460 | 460 | 460 | 460 | 500 | 500 |

| Column Distance | mm | 1140 | 2010 | 2700 | 3600 | 2700 | 3600 | 2700 | 3600 |

| Throat Depth | mm | 300 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Ram Stroke | mm | 160 | 200 | 200 | 200 | 200 | 200 | 240 | 240 |

| Fast Down Speed | mm/s | 240 | 240 | 240 | 240 | 200 | 200 | 200 | 200 |

| Working Speed | mm/s | 10-15 | 10-15 | 10-15 | 10-15 | 10-14 | 10-14 | 10-14 | 10-14 |

| Return Speed | mm/s | 220 | 220 | 220 | 220 | 200 | 200 | 200 | 200 |

| Motor Power | kW | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 | 7.5*2 | 7.5*2 | 7.5*2 | 7.5*2 |

| Oil Tank Capacity | L | 40*2 | 40*2 | 40*2 | 40*2 | 65*2 | 65*2 | 65*2 | 65*2 |

| Overall Dimensions | Length (mm) | 1700 | 2700 | 3400 | 4300 | 3500 | 4300 | 3500 | 4300 |

| Width (mm) | 1540 | 1600 | 1600 | 1600 | 1650 | 1650 | 1900 | 1900 |

| Height (mm) | 2350 | 2400 | 2500 | 2550 | 2630 | 2630 | 2750 | 2750 |

| Machine Weight | kg | 3800 | 7500 | 9800 | 11500 | 11800 | 13800 | 14700 | 16000 |

Key Features and Advantages

1. CNC Control System

The CNC control system is at the core of the 100T 2500mm CNC Hydraulic Double Servo Press Brake, providing precise and easy control over the entire bending process:

Advanced CNC Software: The system uses cutting-edge software that allows the operator to program part specifications, bend angles, material types, and more. This system automatically adjusts the machine’s operations to ensure that each part is bent precisely to the required specifications.

Intuitive User Interface: The touchscreen interface makes programming and operation simple. Operators can easily input parameters for various metal types, thicknesses, and bend angles, minimizing the risk of human error.

Multi-Axis Control: The CNC system supports multi-axis control, allowing the operator to manage the bending and backgauge axes simultaneously for highly complex or multi-bend parts. This ensures that multiple axes move simultaneously and work in perfect synchronization, achieving optimal bend quality and consistency.

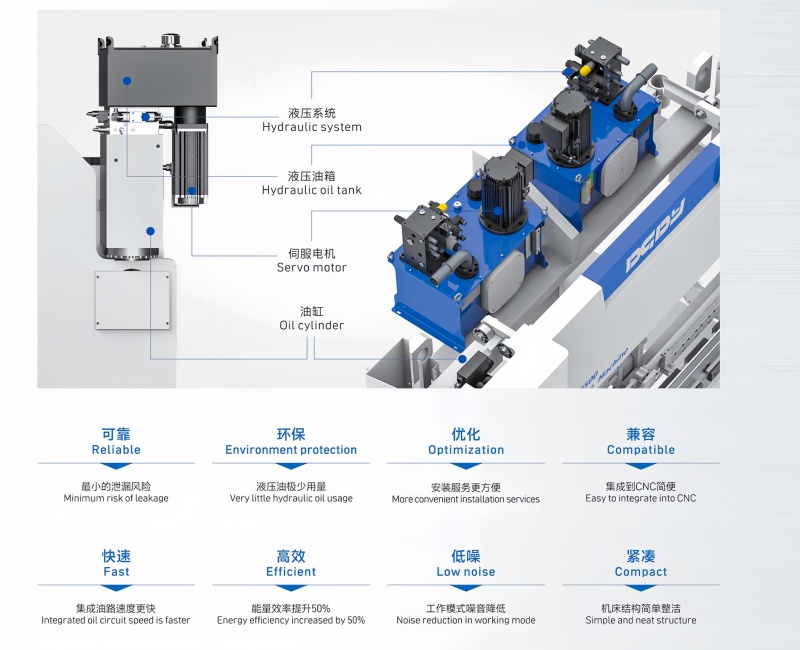

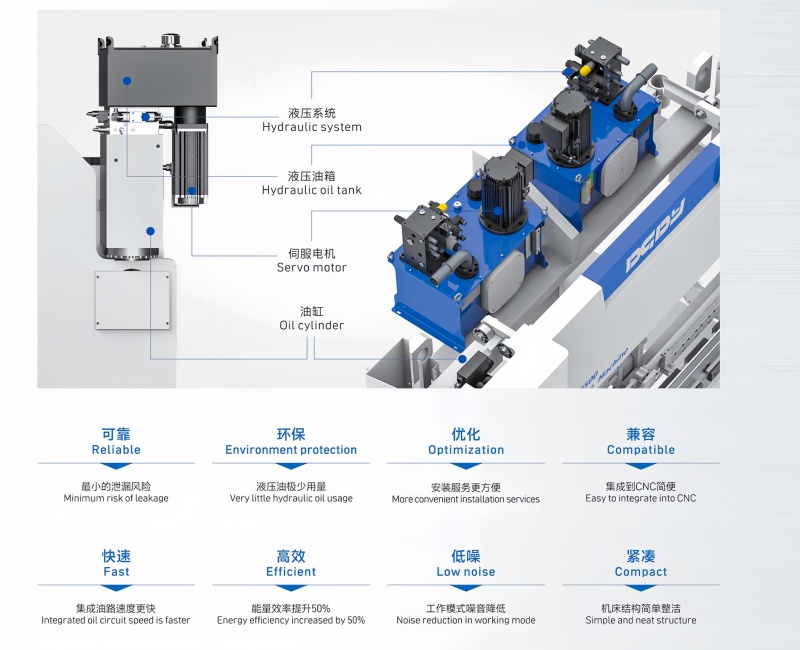

2. Hybrid Drive Technology (Double Servo + Hydraulic)

One of the standout features of this machine is its hybrid drive system, which integrates servo-electric technology with traditional hydraulic power to achieve a balance of efficiency, precision, and cost savings:

Dual Servo Motors: The servo motors are used to precisely control the machine's movements. Servo-electric drives are highly efficient, reducing the overall power consumption by up to 50% compared to conventional hydraulic press brakes. Servo motors only use power when needed, providing on-demand force for the bending operation, which results in lower operational costs and less energy consumption.

Hydraulic Support: The hydraulic system provides additional force for larger, more demanding bending operations, ensuring the machine can handle thick or high-strength materials with ease. The combination of servo motors and hydraulic power optimizes both precision and capacity, making the press brake adaptable to various production requirements.

Energy Efficiency: The hybrid system is designed to reduce energy consumption and operational costs. The machine’s overall power consumption is significantly lower than traditional all-hydraulic press brakes, making it a more environmentally friendly choice.

3. Bending Force and Length

With a 100-ton bending force, the 100T 2500mm CNC Hybrid Press Brake is capable of bending medium to heavy gauge sheet metal. The machine offers:

Bending Length of 2500 mm: This allows the press brake to handle a wide range of metal sheet sizes, providing flexibility for different part lengths and production types.

Adaptability to Various Materials: The machine can handle a variety of materials, including steel, stainless steel, aluminum, and copper, and is effective in both standard and complex bending operations.

4. Maximum Opening Height and Stroke

The machine provides the following specifications for greater flexibility:

Maximum Opening Height: The maximum opening height is 460 mm, allowing for thicker sheets and larger workpieces to be processed. This also provides more clearance for the material during forming, making it easier to handle larger or more intricate parts.

Ram Stroke: The machine features a 200 mm ram stroke, providing optimal flexibility for different sheet thicknesses and bending processes. This ensures that the ram moves smoothly and efficiently during the bending cycle, helping to reduce part distortion and improve quality.

5. Fast Downward and Return Speeds

The 100T 2500mm CNC Hydraulic Double Servo Press Brake is designed for high productivity with fast downward and return speeds:

Fast Downward Speed: The machine has a downward speed of 240 mm/s, which accelerates the cycle time for each bending operation and improves overall throughput.

Return Speed: The machine features a return speed of 220 mm/s, ensuring that the ram moves back quickly to the starting position after each bend, allowing for faster transitions between bends and reducing the overall processing time.

6. Backgauge System

The backgauge system of this press brake is controlled via the CNC system and plays a crucial role in ensuring precise part positioning for each bend:

Multi-Axis Backgauge: The backgauge is adjustable and moves along multiple axes to ensure accurate alignment of the sheet metal. This allows for better control over part placement, ensuring that each bend is precise, even for large or complex parts.

Automatic Adjustments: The backgauge system automatically adjusts according to the programmed part specifications, enabling faster setups and more consistent results.

7. Precision and Repeatability

Consistent Bend Accuracy: The press brake uses servo-driven control for precise movements, allowing for highly accurate and repeatable bends. This is especially important in industries where tolerances are critical, such as automotive and aerospace manufacturing.

Springback Control: The hybrid drive system helps minimize the effects of springback (the tendency of metal to return to its original shape after bending), ensuring that parts stay within the required tolerances and minimizing the need for rework.

8. Safety Features

The 100T 2500mm CNC Hybrid Press Brake is designed with safety in mind. Some of the key safety features include:

Light Curtains: These light sensors detect the presence of an operator or obstructions, automatically stopping the machine if necessary to prevent accidents.

Safety Shields and Enclosures: The machine is equipped with shields to prevent accidental contact with the moving parts of the press brake.

Emergency Stop: The press brake is equipped with easily accessible emergency stop buttons to immediately halt the machine if needed.

9. Versatility and Applications

The 100T 2500mm CNC Hydraulic Double Servo Press Brake is versatile and suitable for a wide range of applications. It is used across many industries, including:

Automotive Manufacturing: For producing body panels, frames, and other structural components.

Aerospace: For the bending of lightweight yet strong materials for aircraft manufacturing.

Metal Fabrication: Ideal for producing custom parts and prototypes, as well as large-scale production runs.

Construction: For bending metal parts used in building structures, supports, and framing.