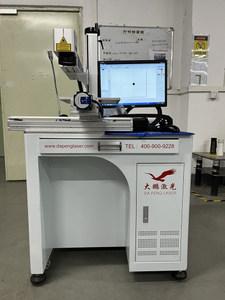

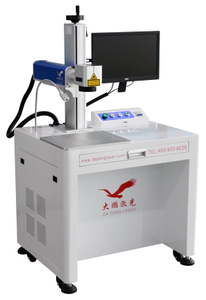

1200mmX1200mm Large Format Fiber Laser Marking Machine

Product application range.

Suitable for large format laser marking of various metal or non-metal products, widely used in the interior of lift doors, bathroom industry, glass mirrors and many other areas of graphic and text marking of large format marking.

Working principle.

Fiber laser marking machine is the use of laser beams on a variety of different material surfaces on the permanent mark. The effect of marking is through the evaporation of the surface material to reveal the deep material, or through the light energy to cause chemical and physical changes in the surface material and "engraved" traces, or through the light energy to burn off part of the material, showing the required etching patterns, text, bar codes and other types of graphics, the so-called fiber laser marking machine is the use of the marking machine is a fiber laser, fiber laser has a small size (no water-cooled device, the use of air-cooled), the beam quality of the light is not only the same, but also the quality of the light. (using air-cooled), good beam quality (base mode), maintenance-free.

Machine features.

⊙ stable laser power output and good spot quality.

⊙ dynamic large format 3D oscillator, fast marking speed.

⊙ No operating system restrictions, easy to operate, fully enclosed optical path, stable, reliable and maintenance-free.

⊙Long life time of over 100,000 hours.

⊙No pollution, no noise, no consumables. ⊙ Power consumption of 5-10% of traditional models

⊙ overcoming the weakness of high anti-material damage to the laser, marking all metals and also engraving most non-metallic materials.

⊙ Ultra high fineness with a resolution of 2540dpi

Software features.

⊙ humanized operation process, good stability of equipment operation; special control software is compatible with Auto CAD, CorelDRAW, Photoshop and other software output

⊙ Can receive a variety of BMP, JPG, DXF, PLT, AI and other format files

⊙ Automatic generation of various serial numbers, production dates, one-dimensional code, two-dimensional code

Main technical parameters:

Category | Model specifications | YLP-100M7-P30-600 |

Laser properties | Central wavelength | 1064nm |

Laser power | 100W |

Beam quality | M2<1.5 |

Repetition frequency | 1-4000KHz |

Pulse width | 2~350ns |

Spot diameter | 7±0.5mm |

Security level | Class IV |

Marking parameters | Marking speed | ≤15000mm |

Repetition accuracy | ±0.001mm |

Minimum characters | 0.15mm |

Minimum marker line width | 32um |

Range of markers | 800x800mm-1200x1200mm |

Other parameters | Cooling methods | Water-cooled (water-cooled for the mirror system, air-cooled for the laser) |

System protection level | IP54 |

Operating environment requirements | Ambient temperature 10-35℃, relative humidity 30%≤RH≤85%, no oil mist, no condensation |

Power requirements | AC220V±5%,50HZ/60HZ,5Amp |

Overall power consumption | <1.6KW |

Complete machine weight | Approx. 250~300kg (without packaging) |

Overall machine dimensions mm (L X W X H) | 1550*800*2060 1940*1050*1940 (Actual to order by marking range)

|

After-sales service.

Service commitment: (abroad)

1. provide wooden boxes and send them to the supplier's port, and the supplier will be responsible for shipping and customs duties.

2. the supply side to provide a one-year warranty on supporting parts, the supply side of the warranty period for the parts sent back to the demand side warranty.

3. If the supplier needs door-to-door service during the warranty period, the supplier is free of labour, but all travel, accommodation and visa costs are borne by the supplier.

Service commitment: (domestic)

4. After the acceptance of the equipment, the quality guarantee period of the whole machine is one year. The system has included a one-year warranty period for service and parts. If there is a quality problem with the parts of the system during the warranty period, our well-trained service engineers will provide telephone or on-site service at any time.

5. During the warranty period, we are responsible for free replacement of parts and services for any damage or injury caused by the quality of the equipment itself, with the exception of regular consumables (e.g. optics, cutting nozzles) and accidents that are the responsibility of the user for non-compliance.

6. After the installation and acceptance of the equipment, our company can send a technician to guide the user at the site for 1-7 days to help the user solve the problems that may be encountered when using the equipment initially.

7. Our company provides lifelong maintenance services for the products provided, and provides daily consultation and guidance related to the equipment at any time. Outside the warranty period, our company still provides extensive and preferential technical support and spare parts supply for the demander.

8. We provide our customers with a long-term reserve of strictly trained and highly qualified operation and maintenance technicians, who are always ready to serve our customers. To solve the customer's trouble of finding technical personnel.

9. After the equipment leaves the factory, our company will establish a "user file card" to track the information related to the use of the equipment by the user. After the equipment maintenance service is completed, our company will report the cause of the failure, remedial measures, the time and date of completion of the repair and return to normal, etc. to the demander, and the report will be made in duplicate for inspection.