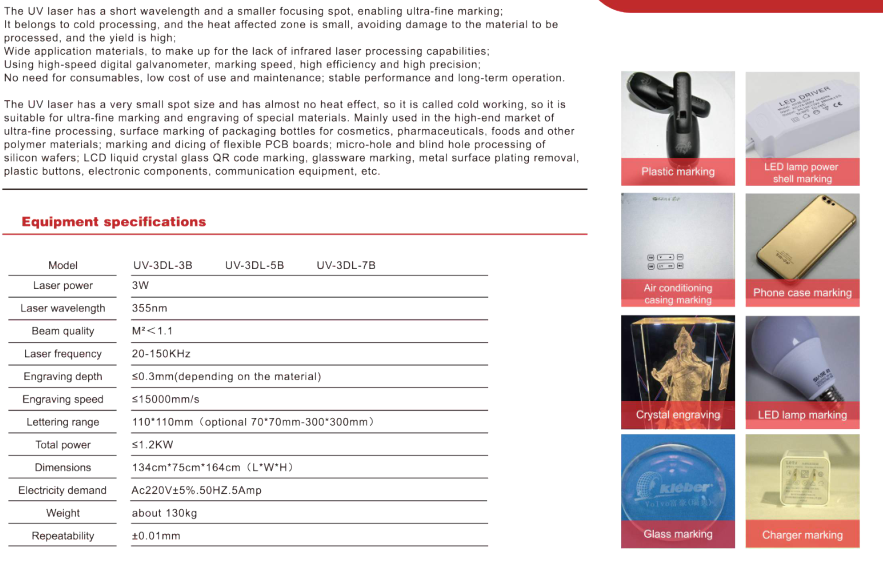

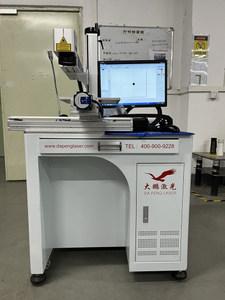

Enclosed UV laser marking machine

The UV laser has a short wavelength and a smaller focusing spot, enabling ultra-fine marking;

It belongs to cold processing, and the heat affected zone is small, avoiding damage to the material to be processed, and the yield is high;

Wide application materials, to make up for the lack of infrared laser processing capabilities;

Using high-speed digital galvanometer, marking speed, high efficiency and high precision;

No need for consumables, low cost of use and maintenance; stable performance and long-term operation.

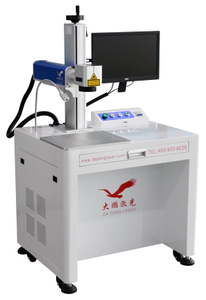

The UV laser has a very small spot size and has almost no heat effect, so it is called cold working, so it is suitable for ultra-fine marking and engraving of special materials. Mainly used in the high-end market of ultra-fine processing, surface marking of packaging bottles for cosmetics, pharmaceuticals, foods and other polymer materials; marking and dicing of flexible PCB boards; micro-hole and blind hole processing of silicon wafers; LCD liquid crystal glass QR code marking, glassware marking, metal surface plating removal, plastic buttons, electronic components, communication equipment, etc.