✅ 1350mm Automatic Sheet Metal Deburring Machine

Heavy-Duty Deburring | Edge Rounding | Surface Finishing | Oxide Removal

Product Description

This 1350mm wide deburring machine is a robust industrial solution for automatic deburring, edge rounding, oxide layer removal, and surface finishing of large sheet metal parts. It is optimized for laser-cut, plasma-cut, sheared, or punched parts and handles carbon steel, stainless steel, aluminum, copper, and other non-ferrous metals.

Engineered for precision, efficiency, and safety, this model provides excellent consistency across a wide range of workpiece sizes.

⚙️ Key Features

Working Width: Up to 1350mm – ideal for larger sheet sizes or batch runs.

Multi-Stage Finishing System:

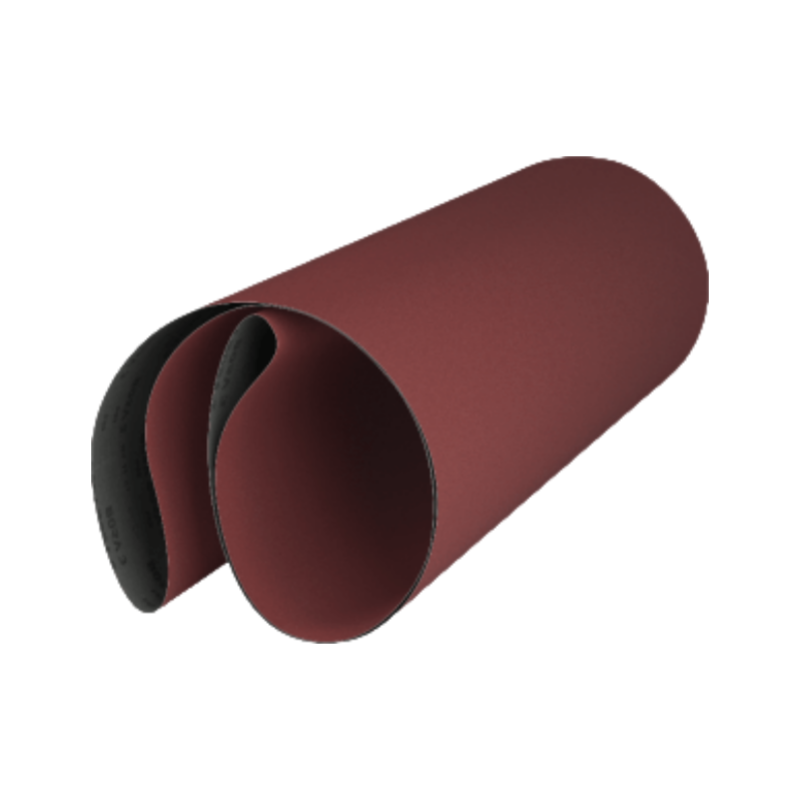

Abrasive belt station for burr and slag removal

Rotating brush station for 360° edge rounding (up to 2mm radius)

Optional oxide removal brushes for clean cutting edges

⚖️ High-Precision Thickness Control:

Optional Vacuum Workholding Table: Ensures small and thin parts remain fixed during processing.

Dust Collection Interface: Compatible with central dust extraction systems for a clean working environment.

Smart Interface (Optional): Touchscreen HMI for easy operation and parameter adjustment.

Typical Technical Parameters

| Specification | Value |

| Max Working Width | 1350mm |

| Processing Thickness | 0.5mm – 80mm |

| Minimum Part Size | 50mm × 50mm |

| Abrasive Belt Size | Φ1910mm × 1350mm |

| Rotary Brush Size | Φ300mm × 300mm |

| Feed Speed | 0.5 – 6 m/min (adjustable) |

| Brush Speed | 500 – 1400 rpm (frequency-controlled) |

| Brush Head Movement | Planetary Rotation + Revolution |

| Power Supply | ~ 36.5kW (varies by configuration) |

| Machine Dimensions | ~ 3200 × 2300 × 2200mm |

| Weight | ~3.5 Tons |

| Dust Extraction Requirement | ≥ 6000 m³/h |

Applications

Laser cut part deburring

Edge rounding before powder coating

Weld prep for sheet metal assemblies

Oxide film removal after thermal cutting

General surface finishing for stainless steel, aluminum, copper, etc.

✅ Why Choose the 1350mm Deburring Machine?

Large Format Capability – Supports wide sheets up to 1350mm

Complete One-Pass Processing – Reduces labor and cycle time

Uniform Edge Rounding – Improves coating adhesion and product safety

High ROI – Reduces rework, increases output quality

Eco-Friendly – Dry processing with optional dust collection; no water or chemicals required