1NM³ 99.999% High Purity Nitrogen N2 Gas Maker Generator (For Laser Cutting and Welding)

The 1NM³ 99.999% High Purity Nitrogen N2 Gas Maker Generator is an advanced solution designed for industrial applications requiring high-quality nitrogen gas, such as laser cutting, welding, and other precision manufacturing processes. This nitrogen generator produces nitrogen with a purity of 99.999%, making it ideal for processes that demand a stable and contaminant-free environment. Its high efficiency and reliability make it a perfect fit for applications in sectors like metalworking, electronics, pharmaceuticals, and food packaging.

Key Features

High Purity Nitrogen Production (99.999%)

The N2 gas maker generator ensures an ultra-high purity of 99.999%, which is ideal for applications where nitrogen is used for blanketing, cutting, welding, or providing an inert atmosphere.

Stable Nitrogen Flow Rate (1NM³/h)

Operating Pressure Range (0.6 - 0.8 MPa)

Compact and Efficient Design

On-demand Nitrogen Supply

Unlike traditional cylinder-based nitrogen supplies, the N2 gas maker generates nitrogen on-site as needed, eliminating the need for storage and reducing operational costs associated with purchasing bottled nitrogen.

Energy Efficient

Applications

The 1NM³ 99.999% High Purity Nitrogen N2 Gas Maker Generator is designed for use in various applications, particularly those that require a consistent, high-purity nitrogen supply:

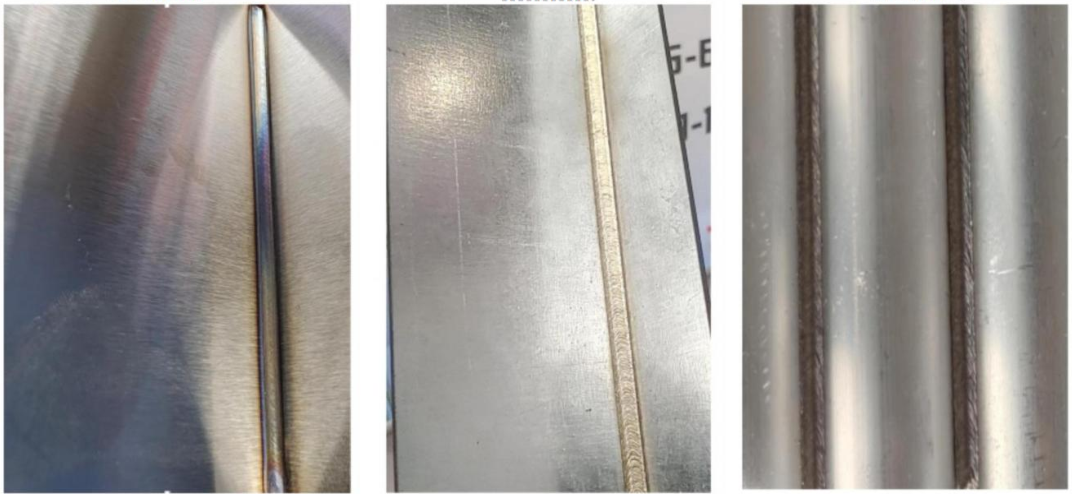

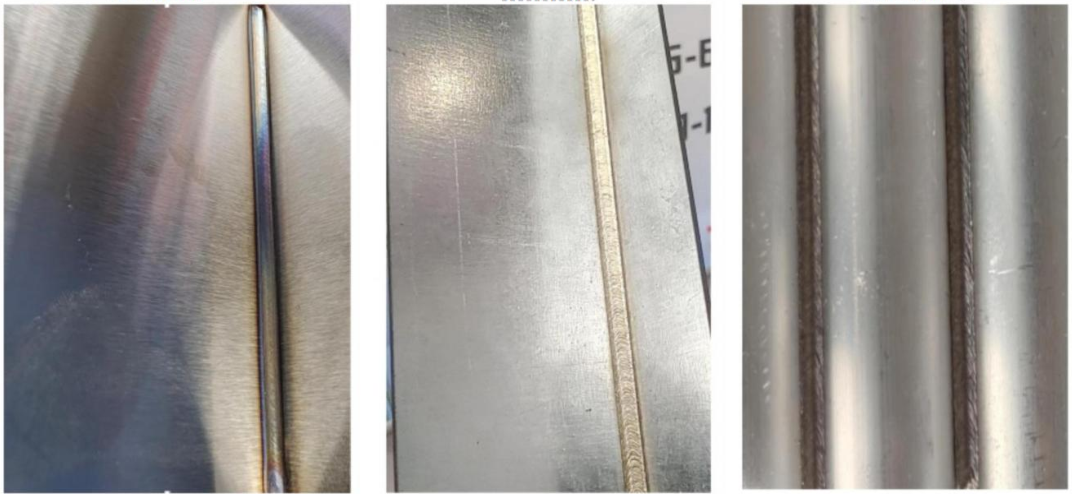

Laser Cutting:

Nitrogen is used in laser cutting applications to prevent oxidation during the cutting process. Its inert properties allow for smooth, clean cuts, especially on metals like stainless steel and aluminum.

Welding:

In welding processes, nitrogen is used as a shielding gas to prevent contamination and oxidation of the weld area. The generator provides a consistent supply of nitrogen to ensure high-quality welds.

Electronics Manufacturing:

Nitrogen is often used in electronics manufacturing to provide an inert atmosphere during assembly and testing, preventing the oxidation of sensitive components.

Food Packaging:

The generator can also be used in food packaging to replace the air inside containers with nitrogen, extending the shelf life of perishable products.

Pharmaceuticals:

In the pharmaceutical industry, nitrogen is used for controlled environments and to preserve the integrity of sensitive products by preventing contamination.

Technical Specifications

| Parameter | Details |

| Model | 1NM³ 99.999% High Purity N2 Gas Maker Generator |

| Nitrogen Flow Rate | 1 NM³/h |

| Nitrogen Purity | 99.999% |

| Inlet Pressure | 0.6 – 0.8 MPa |

| Output Pressure | ≤ 0.6 MPa |

| Power Consumption | 15W |

| Supply Voltage | AC 220V |

| Dimensions (L×W×H) | 780X500X450 mm |

| Air Inlet | 8mm air pipe |

| Nitrogen Outlet | 6mm air pipe |

Operating Instructions

Connect Compressed Air:

Ensure that the air source is dehydrated and deoiled before connection to the nitrogen generator. This will protect the system from contaminants.

Power On:

Switch on the generator and monitor the AB towers (molecular sieve towers), which will alternate operation to produce nitrogen.

Monitor Nitrogen Pressure:

The nitrogen pressure will gradually increase to the specified level, and you can begin using the generated nitrogen after approximately 40-50 minutes.

Shutdown Procedure:

After use, close all nitrogen outlet valves, turn off the power switch, and ensure that the nitrogen pressure is maintained at the highest level for optimal performance upon the next startup.

Maintenance and Care

Routine Cleaning:

Disconnect the power supply and release the internal pressure before cleaning the nitrogen generator. Use non-corrosive cleaning agents to clean the outer shell and replace the filters as necessary.

Filter Replacement:

Regularly check and replace the filters inside the nitrogen generator to ensure the system continues to produce high-purity nitrogen and operates efficiently.

Drying Process:

After cleaning, allow the nitrogen generator to dry completely before powering it back on.

Avoid Overpressure or Overheating:

Do not operate the generator under overpressure or overtemperature conditions to ensure the longevity of the system.

Conclusion

The 1NM³ 99.999% High Purity Nitrogen N2 Gas Maker Generator offers an efficient and reliable on-site nitrogen generation solution, ideal for applications such as laser cutting, welding, electronics manufacturing, and food packaging. With its high purity output, energy-efficient design, and easy-to-use features, it ensures a steady, cost-effective supply of nitrogen gas without the need for bulky storage tanks. This generator is perfect for industries looking to streamline their operations and reduce costs while maintaining the highest standards of quality.