CNC sheet metal folding machine is a high-precision automated tool designed for bending and shaping sheet metal. It operates using a computer numerical control (CNC) system to manage the machine's movements with high accuracy and consistency. These machines are widely used in industries such as automotive, aerospace, construction, and electronics to create complex metal components with precise bends and folds.

TB025 CNC Sheet Metal Folding Machine

Precision, Efficiency, and Flexibility in Modern Metalworking

The TB025 CNC Folding Machine is a high-performance sheet metal forming solution designed for small to medium workshops as well as large manufacturing plants that demand precision, consistency, and productivity. Engineered with advanced CNC control and a robust mechanical design, the TB025 offers outstanding performance in folding and bending sheet metal parts. With a working length of 2500 mm and a maximum carbon steel thickness of 2.0 mm, this model is versatile enough to handle a wide variety of sheet metal applications across industries such as construction, electrical enclosures, HVAC systems, furniture, elevators, doors, windows, and stainless-steel products.

Key Features and Functions

1. CNC Control for Accuracy

The TB025 comes equipped with a modern CNC control system, allowing operators to program folding angles, back gauge positions, and clamping sequences with ease. With multi-axis synchronization, the system guarantees repeatable accuracy in every fold, reducing human error and setup time.

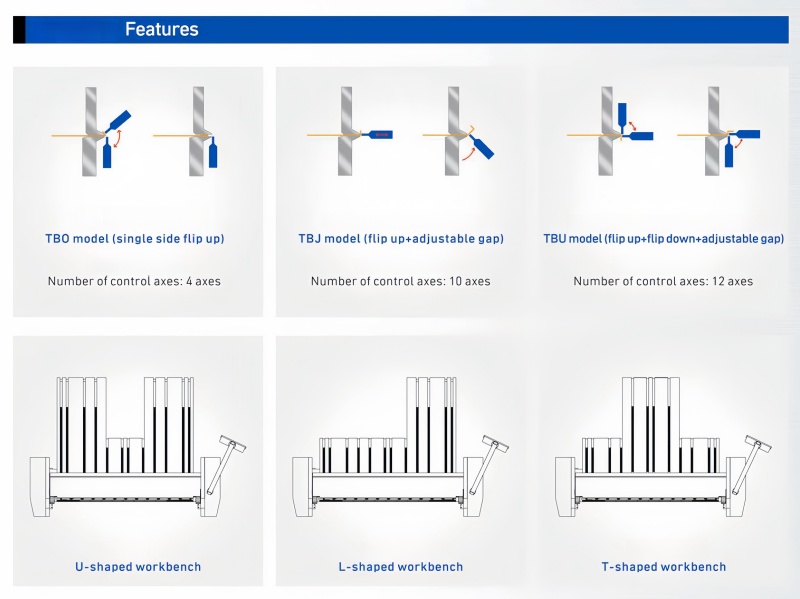

Control Axes: 4

Bending Angle Range: 45° to 180°

Back Gauge Length: up to 2500 mm

Touchscreen Interface: intuitive operation and quick program adjustments

2. Strong Structural Design

The TB025 features a rigid welded steel frame designed to absorb vibration and provide stability during heavy-duty bending operations. The combination of structural integrity and optimized drive mechanics ensures smooth folding with consistent quality.

3. Efficient and Fast Operation

With a pressing speed of 200 mm/s and a folding speed of 100°/s, the TB025 ensures rapid cycle times while maintaining precision. This balance between speed and control allows manufacturers to achieve higher throughput without compromising quality.

Clamping Speed: 200 mm/s

Folding Speed: 100°/s

4. Energy-Saving Drive System

Equipped with a 3.5 kW energy-efficient motor, the TB025 provides ample power for bending tasks while minimizing electricity consumption. This results in lower operational costs and a greener production process.

5. Flexible Folding Capabilities

The machine is capable of processing different materials, including carbon steel, stainless steel, and aluminum, making it suitable for diverse production needs.

Carbon Steel Thickness: up to 2.0 mm

Stainless Steel Thickness: up to 1.5 mm

Maximum Bending Length: 2500 mm

6. Tooling Compatibility

The TB025 uses standardized tooling with a height of 125 mm, allowing quick changeovers for different jobs. This flexibility reduces downtime and enables manufacturers to meet varied customer requirements.

Performance Advantages

High Precision

The CNC system controls each movement with great accuracy, ensuring repeatable bending angles and consistent dimensions across large batches. This is particularly important for industries such as HVAC or electrical enclosures, where exact fitting is required.

Productivity Boost

The combination of high clamping speed, fast folding cycles, and CNC programming allows the TB025 to process hundreds of parts per shift, meeting the needs of medium-scale production lines.

Operator-Friendly

With its ergonomic design, the TB025 is comfortable to operate. The touchscreen interface simplifies programming, while the accessible clamping area reduces operator fatigue. Even operators with minimal training can achieve high-quality results after a short learning curve.

Reduced Setup Time

Programs can be stored and recalled quickly, which reduces preparation time for repeat jobs. This is highly beneficial for workshops dealing with multiple product variants.

Durability and Reliability

The heavy-duty frame, precision components, and CE-compliant safety systems ensure long service life and reliable operation. Maintenance is straightforward, with easy access to mechanical and electrical parts.

Applications of the TB025 CNC Folding Machine

The TB025 is widely used in industries that require precise folding of sheet metal parts. Typical applications include:

1. Construction and Building Components

2. HVAC and Ventilation

3. Electrical and Control Cabinets

4. Furniture and Interior Design

5. Elevators and Transportation

6. Appliances and Consumer Goods

Washing machine panels

Refrigerator doors

Stainless steel sinks

Why Choose the TB025?

Compact yet Powerful – With a working length of 2500 mm, the TB025 is suitable for both small shops and larger production environments.

Precision Folding – CNC accuracy ensures consistent results across high-volume production.

Energy Efficiency – Low power consumption reduces production costs.

Flexibility – Capable of handling different sheet thicknesses and materials.

Cost-Effective – Combines advanced features with competitive pricing, ensuring high return on investment.

Safe and Certified – Built to CE standards with comprehensive safety systems.

Optional Equipment and Upgrades

Automatic Tool Change System – For quick tooling setup

Laser Angle Measurement – Ensures perfect folding angles in real time

Hydraulic or Servo Drive Options – Customized for production needs

Dust and Fume Extraction System – Improves workshop environment

Automatic Loading/Unloading Units – For higher automation levels

Technical Specifications (TB025)

| Item | Unit | TB025 |

| Max. Sheet Thickness (Carbon Steel) | mm | 2.0 |

| Max. Sheet Thickness (Stainless Steel) | mm | 1.5 |

| Bending Angle Range | ° | 45–180 |

| Max. Bending Length | mm | 2500 |

| Back Gauge Length | mm | 2500 |

| Open Height | mm | 380 |

| Tool Height | mm | 125 |

| Control Axes | — | 4 |

| Clamping Speed | mm/s | 200 |

| Folding Speed | °/s | 100 |

| Motor Power | kW | 3.5 |

| Machine Dimensions (L × W × H) | mm | 3100 × 3700 × 1650 |

| Machine Weight | Kg | 3500 |

Conclusion

The TB025 CNC Sheet Metal Folding Machine is an ideal solution for companies seeking a balance between compact size, high precision, and strong performance. It is particularly well-suited for medium-scale production environments where flexibility, accuracy, and cost-efficiency are crucial. By integrating CNC technology, robust mechanics, and user-friendly operation, the TB025 enables manufacturers to achieve superior productivity while ensuring consistent product quality.

With its proven reliability and versatile applications, the TB025 is not only a machine but also a long-term investment in the future of precision sheet metal manufacturing.

Technical Parameters

| Item | Unit | TB025 | TB032 | TB041 | TBU25 | TBU32 | TBU41 |

| Processing thickness | mm | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Processing thickness (stainless steel) | mm | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Bending length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Bending angle | degrees | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 |

| Speed | mm/s | 30 | 30 | 30 | 30 | 30 | 30 |

| X-axis travel | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Y-axis travel | mm | 100 | 100 | 100 | 100 | 100 | 100 |

| Z-axis travel | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Main motor power | kW | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Dimensions (L x W x H) | mm | 3100x1800x3100 | 3700x1800x3100 | 4500x1800x3100 | 3100x1800x3100 | 3700x1800x3100 | 4500x1800x3100 |

| Weight | kg | 3500 | 4500 | 7500 | 4000 | 6000 | 8000 |

This table shows key specifications such as processing thickness, bending length, bending angle, speed, axis travel ranges, motor power, dimensions, and weight for different CNC folding machine models.