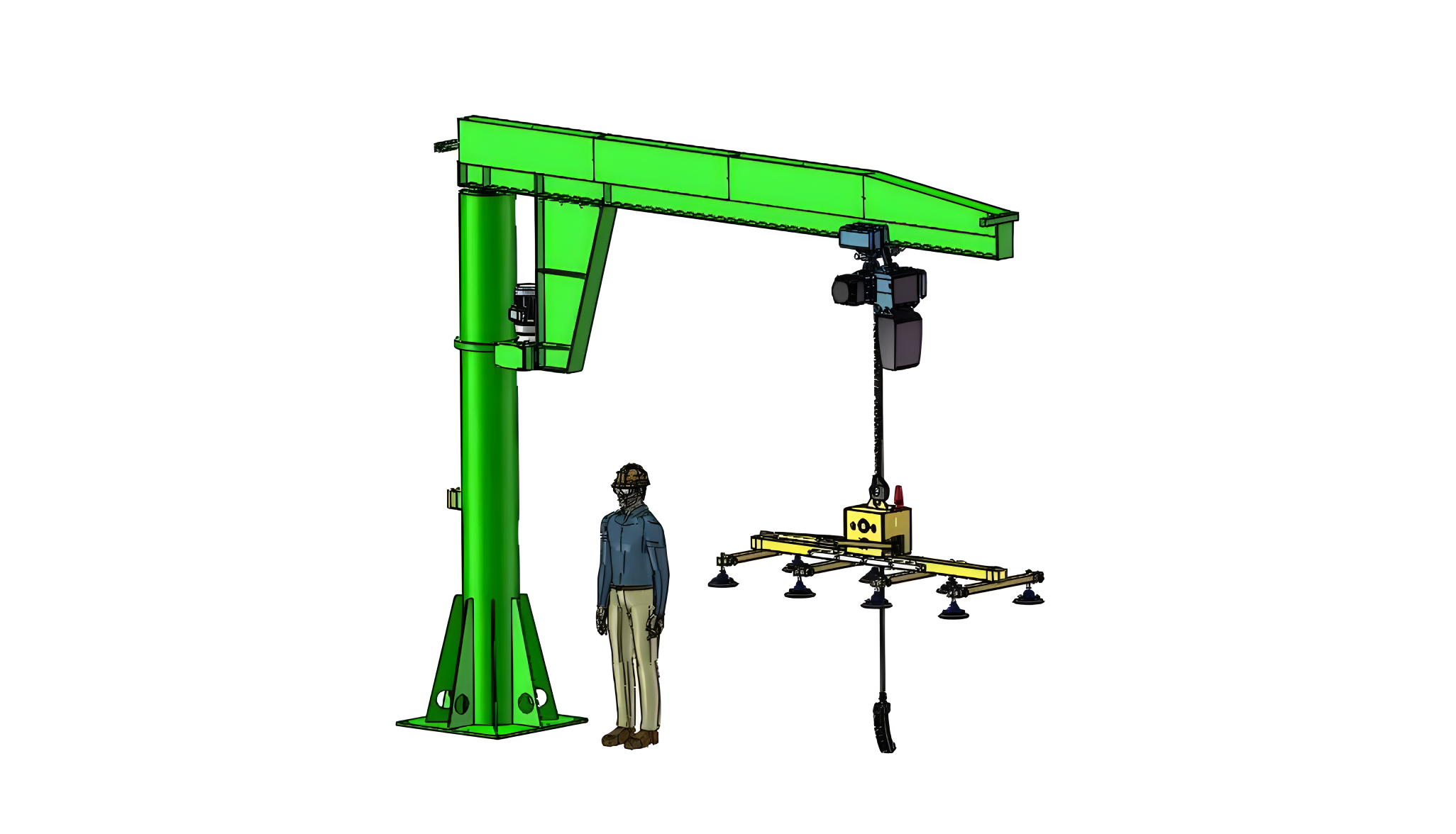

380V/220V Electric Vacuum Lifter for 1000kg Metal Sheets

The 380V/220V Electric Vacuum Lifter is a robust lifting system designed to safely and efficiently handle heavy-duty materials, including metal sheets with a weight of up to 1000kg. This electric vacuum lifter uses a powerful suction mechanism to lift, move, and position large metal sheets, enhancing productivity in manufacturing, construction, and metalworking industries. It is suitable for lifting metal sheets such as stainless steel, aluminum, and other heavy materials.

Key Features:

High Lifting Capacity:

Capable of handling metal sheets weighing up to 1000kg.

Ideal for industrial applications requiring the lifting of large and heavy metal sheets in workshops, warehouses, and fabrication plants.

Dual Voltage Operation:

Available in 380V or 220V configurations to suit different power requirements in industrial environments.

The 380V model is typically used in larger operations, while the 220V model is suitable for smaller-scale applications.

Electric Powered Suction:

Equipped with an electric vacuum pump that generates a strong, consistent vacuum to lift metal sheets securely.

The electric system provides precise control over the lifting process, offering a safer and more efficient operation compared to manual lifting methods.

Easy Handling and Maneuverability:

Designed with a user-friendly interface and controls for ease of operation.

Includes a vacuum suction cup system that can securely grip metal sheets without causing any surface damage.

The system is equipped with tilt and rotation functions to allow precise positioning of the metal sheets.

Built for Durability:

The high-quality materials used in construction ensure long-lasting durability even under harsh working conditions.

The lifting system is designed to withstand the weight of 1000kg metal sheets without compromising its performance or safety.

Safety Features:

Features automatic safety systems to monitor the vacuum levels and prevent sudden drops or slippage.

Equipped with emergency stop buttons, overload protection, and fail-safe mechanisms to ensure user safety during operation.

Versatile Applications:

Perfect for use in industries such as metal fabrication, sheet metal processing, construction, steel mills, and automotive manufacturing.

Suitable for lifting and moving large panels, metal plates, and other flat materials.

Energy Efficient:

Customizable Features:

Applications:

Metalworking Industry: Efficiently lifts and positions heavy metal sheets used in manufacturing processes.

Construction: Moves large, heavy panels and materials for building projects.

Manufacturing Plants: Ideal for lifting and placing large metal components or machinery.

Warehouses: Used for loading/unloading metal sheets, reducing the risk of injury during manual lifting.

Vacuum Lifter

| Product Model | JS-J1000-5M | JS-C1000-5M |

| Rated Load (kg) | 1000 | 1000 |

| Suction Cup Diameter (mm) | 200 | 200 |

| Number of Suction Cups | 12 | 12 |

| Outer Dimensions (mm) | 5000*1000 | 5000*1000 |

| Plate Dimensions (mm) | 6000*2000 | 6000*2000 |

| Working Voltage | DC12V | 380V/220V |

Typical Equipment Applications:

Sheet Metal Processing Industry: Primarily used for loading and unloading sheets in laser cutting, stamping, bending, and other processes.

Metal Processing Plants: Suitable for bulk handling and stacking of metal sheets, especially during long-term, high-frequency operations, where automated equipment can effectively reduce errors and waste.

Home Appliance Manufacturing: Automated handling equipment can be used for transporting materials like refrigerator, washing machine, and air conditioner shells, enhancing the level of automation in production lines.

Automotive Manufacturing: In the processing of automotive body panels, automatic stacking and handling equipment ensures the safe transport of large sheet metal parts.