Machine Features and Specifications

This machine is designed for deburring, edge rounding, and surface treatment of sheet metal, including processes like surface brushing, oxidation skin removal, and polishing. It uses a combination of a flap wheel station and a sand belt station to handle different types of deburring and finishing tasks.

Main Features:

Material Compatibility: Steel, Aluminum, Stainless Steel, and other metals.

Processing Range: Suitable for deburring, edge rounding, and surface finishing.

Working Width: Up to 800mm

Processing Thickness: 0.5 - 80mm

Minimum Workpiece Size: 50mm x 50mm (for solid, non-holed workpieces)

Key Components:

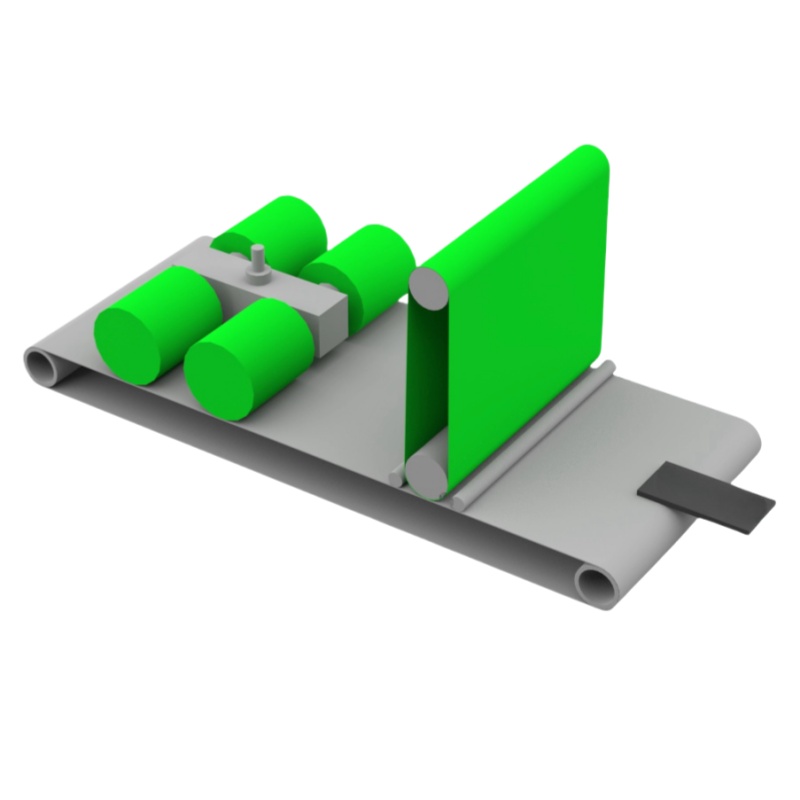

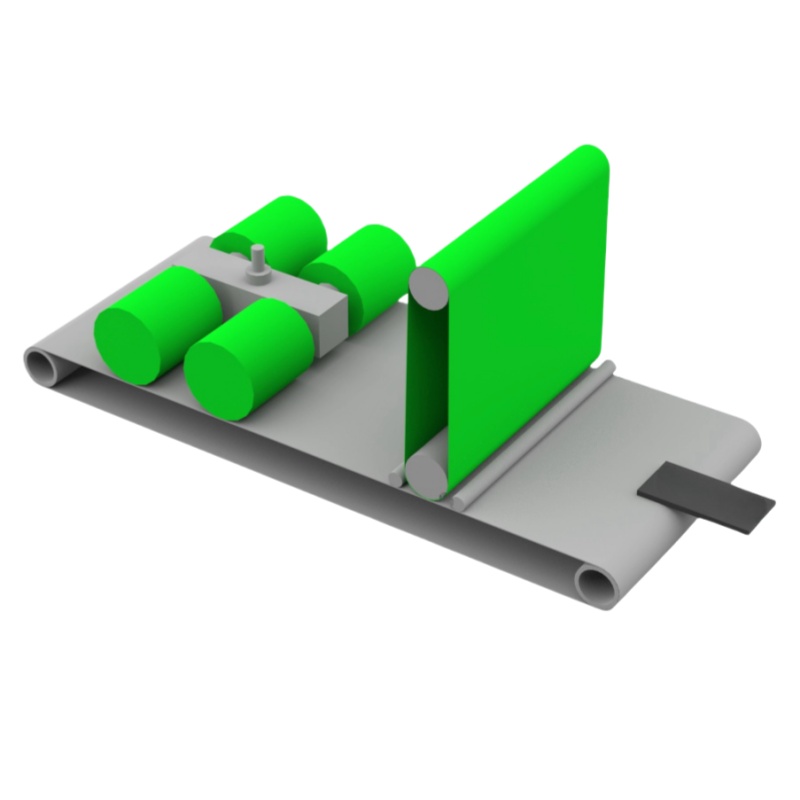

Flap Wheel Station: Handles the deburring and edge rounding of metal workpieces with a diameter of Ø300mm x 3000mm. It works in high-speed centrifugal actions to eliminate burrs from edges and holes, while achieving a smooth and rounded edge (approximately 0.2-0.5mm R radius, adjustable based on abrasive material and process).

Sand Belt Station: Used for removing slag particles, oxide skin, and polishing the surface of the metal sheet. The sand belt size is Ø1910mm x 800mm.

Additional Specifications:

| Specification | Value |

| Machine Power | 30.25KW (Excluding Dust Extraction) |

| Conveyor Speed | 0.5 ~ 6 m/min (Variable Speed) |

| Sand Belt Line Speed | Approx. 18 m/s |

| Flap Wheel Speed (Self Rotation) | 8 ~ 26 m/s (Variable Speed) |

| Flap Wheel Planetary Rotation Speed | 1 ~ 15 rpm (Variable Speed) |

| Flap Wheel Planetary Heads (Self Rotation) | 4 |

| Flap Wheel Compensation Adjustment Precision | 0.01mm |

| Grinding Consumables | Sand Belt + Flap Wheel |

| Dust Extraction Airflow | 4000 m³/h |

| Machine Dimensions (L x W x H) | 2650mm x 1650mm x 2150mm |

| Machine Weight | Approx. 2.2T |

Machine Functionality:

Deburring: The machine removes burrs from edges and holes through flap wheels and sand belt stations.

Edge Rounding: Achieves small R radius edges (0.2-0.5mm), adjustable based on the choice of abrasive materials.

Surface Treatment: Polishing and oxide skin removal from metal surfaces.

Independent Operation: Both the flap wheel and sand belt stations can operate independently to meet specific processing needs.