800mm Sheet Metal Deburring and Finishing Machine

The C800 sounds like a very versatile and robust machine, offering a great range of options for sheet metal finishing. The ability to adjust the conveyor system based on whether you're using a vacuum or magnetic system gives flexibility depending on the material being processed, which is ideal for different job requirements.

The combination of a grinding unit in the first station and oscillating brushes in the second and third stations really sets this machine apart. It ensures a consistent, smooth finish while also offering the flexibility to remove sharp edges or apply a larger radius. Plus, the ability to tackle oxide skin and slag removal from steel parts using special brushes makes it perfect for handling more demanding materials.

Efficient processing of compact sheet metal parts

Unique brush system, stable grinding belt

Fully automatic adjustable stations

Intuitive, multilingual HMI touchscreen

Reproduce with adjustable programs

Would you be using this machine for a specific range of materials or processes, or are you looking for something that can handle a variety of sheet metals?

Key Features:

Multilingual HMI Touchscreen: User-friendly interface for easy operation and monitoring.

Reproducible Finish Quality: Adjustable programs for consistent results.

Automatic Brush Calibration: Ensures precise brush performance.

Height Adjustment of Grinding Unit: Fully automatic, providing flexibility for different workpieces.

Qonnect+ Integration: ERP, handling, and process integration for smarter production management.

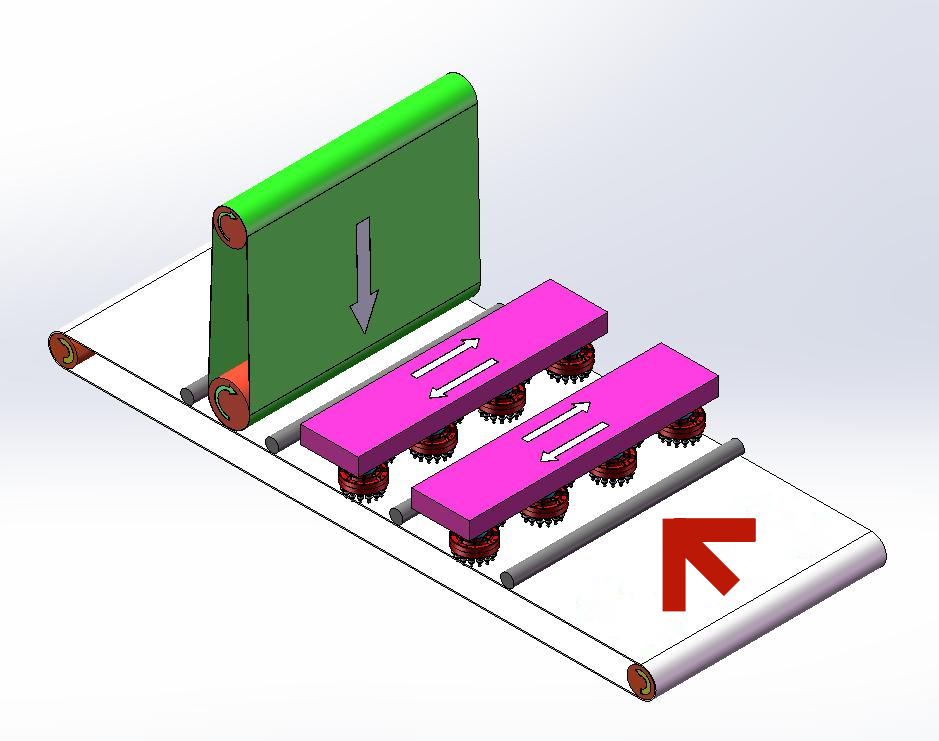

Working Principle:

Grinding Station: The first station uses a grinding belt to remove burrs, resulting in a flat, burr-free surface.

Oscillating Disc Brushes: Four brushes apply light pressure to round both inner and outer contours.

Multibrush Station: The final stage employs six Multibrushes to give a non-directional finish and round edges with a radius of 2+ mm, ensuring the product has a high-quality, durable appearance.

Conveyor System:

Vacuum Negative Pressure: Securely holds workpieces during processing.

Through-feed Mode: Can process parts as small as 50mm x 50mm (no holes, thickness 0.5-10mm) without tooling, or special tooling can be added for custom parts.

Variable Frequency Speed Control: Allows stepless adjustment of the conveyor speed from 0.5 to 6 m/min.

Main Technical Parameters:

| Parameter | Value |

| Processing Width | ≤ 780mm |

| Processing Thickness | 1 ~ 80mm |

| Minimum Processing Size | 50mm x 50mm |

| Total Machine Power | ≤ 33.95KW (excluding dust extraction) |

| Sand Belt Size | 1910 x 800mm |

| Steel Hammer Brush Diameter | Φ 162mm |

| Conveyor Speed | 0.5~6 m/min (adjustable) |

| Sand Belt Linear Speed | 18 m/s |

| Processing Thickness Servo Adjustment Accuracy | 0.01mm |

| Grinding Consumables | Steel hammer brush + abrasive belt |

| Dust Extraction Volume | 4000 m³/h |

| Approximate Equipment Dimensions | 2700mm (L) x 1700mm (W) x 2300mm (H) |

| Approximate Machine Weight | 2.6T |