ZHN-05 Industrial Nitrogen Generation System for Laser Welding Applications

The ZHN-05 represents an advanced pressure swing adsorption (PSA) nitrogen generation solution specifically engineered for high-demand laser welding operations. This system delivers reliable, on-site nitrogen production to support 5-6 simultaneous laser welding/cutting machines with industrial-grade performance.

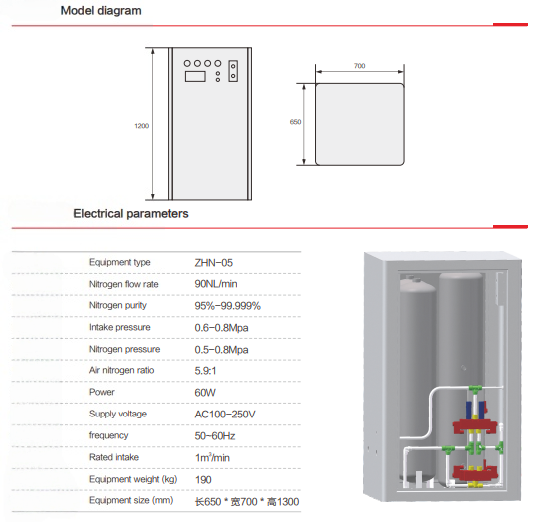

Technical Specifications

Flow Capacity: 90 Nm³/min continuous output

Purity Range: 95-99.999% (adjustable)

Operating Pressure: 0.6-0.8MPa intake, 0.5-0.8MPa output

Power Requirements: 60W, AC 100-250V 50/60Hz

Dimensions: 650×700×1300mm (L×W×H)

Weight: 190kg

Standard Features: Integrated digital purity analyzer, automatic pressure regulation

Core Technology

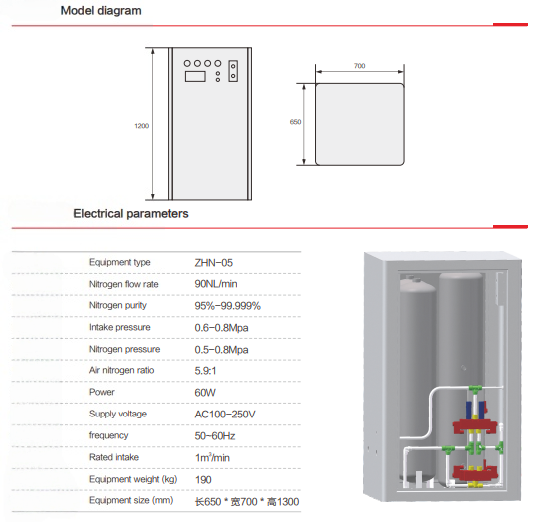

The system utilizes a dual-tower PSA (Pressure Swing Adsorption) configuration with:

High-grade carbon molecular sieve (CMS) beds

Precision pressure equalization system

Multi-stage filtration (0.01μm particulate)

Automatic tower switching mechanism

Performance Characteristics

Gas Quality

Efficiency Metrics

Air-to-nitrogen conversion ratio: 5.9:1

Compressed air consumption: 31m³/min

Start-up time: <15 minutes to full purity

Durability Features

Industrial-grade stainless steel framework

IP54 protection rating

Designed for 24/7 continuous operation

Maintenance interval: 4000 operating hours

Laser Welding Applications

The ZHN-05 provides critical nitrogen support for:

System Advantages

Operational Benefits

Eliminates cylinder handling

Removes gas delivery dependencies

Provides unlimited supply continuity

Reduces gas costs by 60-80%

Quality Improvements

Safety Features

Overpressure protection

Low pressure alarms

Emergency shutdown

Leak detection

Installation Requirements

Floor space: Minimum 1.5×2m area

Compressed air supply: Oil-free, dew point ≤3°C

Ambient conditions: 5-40°C operating temperature

Ventilation: 10 air changes/hour recommended

Maintenance Protocol

Daily: Drain condensate, check pressures

Weekly: Filter inspection

Monthly: CMS bed testing

Annual: Full system service

Comparison to Alternatives

The ZHN-05 offers distinct advantages over:

Liquid nitrogen dewars (higher purity but costly)

Cylinder banks (space intensive)

Membrane systems (lower purity)