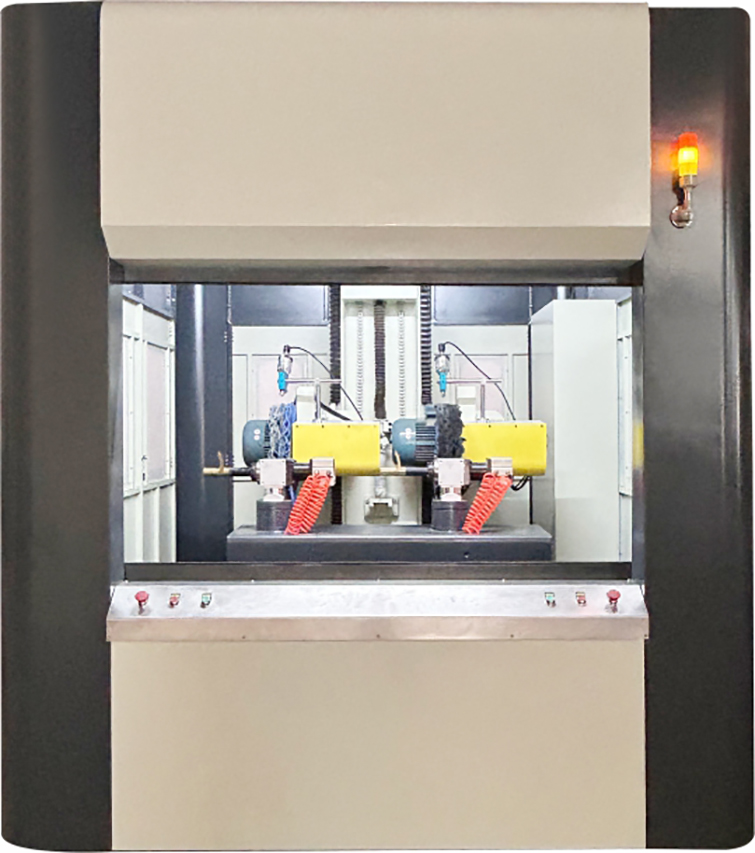

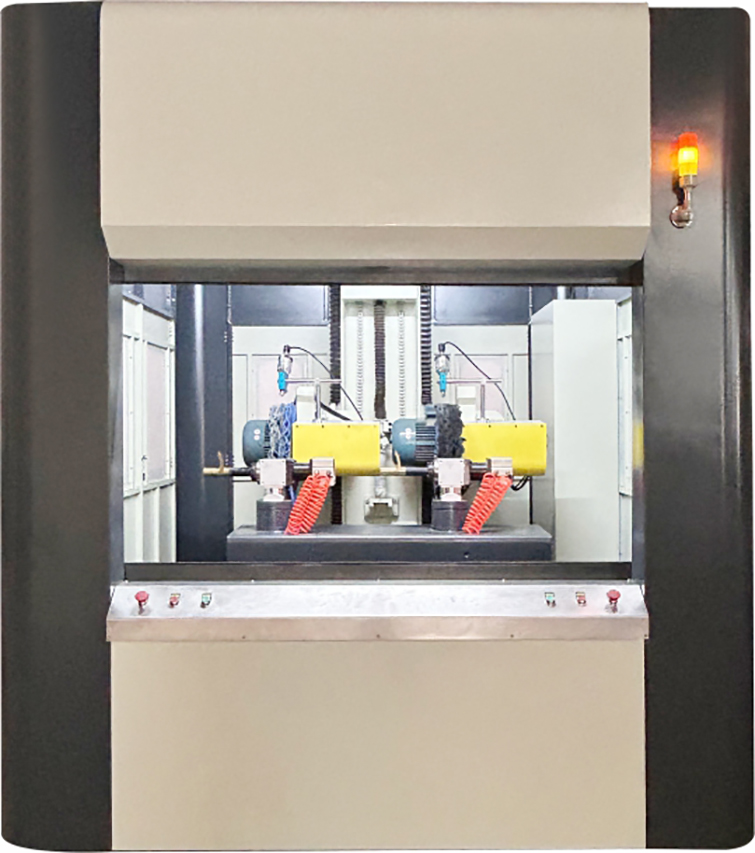

CNC Metal Polishing Machine for Polishing and Brightening Basin Faucet, Kitchen Faucet, Bath Faucet

Introduction

The CNC Metal Polishing Machine is a highly advanced automated system designed for polishing and brightening metal surfaces, particularly for applications in the production of faucets such as basin faucets, kitchen faucets, and bath faucets. With the capability to deliver a flawless, mirror-like finish, these machines ensure that high-quality sanitary hardware is produced efficiently and consistently. Ideal for manufacturers of faucets and other metal bathroom accessories, this machine integrates precision technology with robust performance to meet the high aesthetic and functional standards required in the market.

Key Features

Advanced CNC Control System:

The CNC Metal Polishing Machine operates with a sophisticated CNC system that ensures precise control of polishing processes. The CNC programming allows for customization of polishing paths, speeds, and pressures tailored to different shapes, materials, and finishes. This results in uniform, high-quality polishing across various product designs.

Multi-Axis Polishing Capability:

Equipped with multiple axes (typically 3, 4, or 5 axes), the machine can move in various directions to polish complex geometries, such as faucets with intricate curves, edges, and surfaces. The multi-axis system ensures that every angle of the product, including difficult-to-reach areas, receives the same consistent finish.

High Precision and Consistency:

CNC control allows for extremely fine tolerances and repeatability. This means that each faucet or bathroom accessory can be polished with the exact same precision, ensuring uniformity in appearance, quality, and texture across a batch of products. This is particularly important in industries where product aesthetics and surface finishes are critical.

Automated Polishing and Brightening:

The machine automates the polishing process, significantly reducing manual labor and the variability associated with human handling. It uses a combination of abrasive pads, buffing wheels, and polishing compounds to achieve a mirror-like finish, removing any imperfections, scratches, or oxidation from the surface of the metal.

Variable Speed and Pressure Control:

The system allows for adjustable speeds and pressures to suit different materials and finishes. For softer metals like brass or Zamak, the pressure can be adjusted to avoid over-polishing, while harder metals can be processed at higher pressures for efficient removal of oxidation and imperfections.

High Throughput and Efficiency:

Thanks to its automated nature, the CNC Metal Polishing Machine offers a high throughput rate. This is especially beneficial for manufacturers that need to process large volumes of faucets and sanitary ware. The machine's efficiency reduces operational costs by minimizing manual intervention and speeding up production.

Dust Collection and Filtration System:

To ensure a clean working environment and comply with safety regulations, the machine is equipped with a robust dust collection and filtration system. This prevents metal dust and polishing residues from contaminating the workplace, ensuring that the products maintain a clean and professional finish.

User-Friendly Interface:

The CNC machine features an intuitive user interface, allowing operators to easily set up and monitor the polishing process. The system can store multiple polishing programs, which can be quickly selected based on the specific requirements of each job.

Applications

Basin Faucets:

The CNC Metal Polishing Machine is widely used in the production of basin faucets, which often require a high-quality, smooth finish to enhance their visual appeal. Polishing and brightening are critical to ensure that the faucets are free from imperfections, oxidation, or dullness, providing an elegant and durable product for bathrooms.

Kitchen Faucets:

Kitchen faucets are subjected to regular exposure to water, oils, and chemicals, making it essential to have a protective, corrosion-resistant, and aesthetically pleasing surface. The machine provides precise polishing that not only improves the look of kitchen faucets but also enhances their resistance to corrosion, maintaining their functionality and appearance over time.

Bath Faucets:

Bath faucets are often designed with more intricate details, and the CNC Metal Polishing Machine is perfect for delivering the fine finishes needed for these products. With its ability to handle various shapes, the machine ensures that even complex designs are polished to perfection, adding value and luxury to bath fixtures.

Shower Heads:

Shower heads, like faucets, need to have a smooth, shiny surface that resists corrosion and maintains its aesthetic appeal. The CNC Metal Polishing Machine ensures that shower heads receive a consistent, high-quality finish that is both durable and visually appealing.

Sanitary Hardware and Accessories:

Beyond faucets and shower heads, this machine is highly versatile and can be used for polishing a wide range of other sanitary hardware, such as towel racks, soap dishes, and bathroom accessories. The machine ensures that each product maintains the highest standards of finish and durability, making it ideal for both high-end residential and commercial applications.

Process Flow

Part Preparation:

Metal parts, such as faucets or shower heads, are placed on the machine's workbed or fixtures. Specialized jigs or clamps are used to secure them in position, ensuring that they are stable throughout the polishing process.

CNC Programming:

Operators program the CNC system to define the polishing path, speed, pressure, and duration based on the product's material and desired finish. The program can be customized for different parts, ensuring optimal results for each unique design.

Polishing:

The CNC machine begins the polishing process using abrasive pads, brushes, or buffing wheels, depending on the material and finish required. The system moves along the programmed path, polishing the product’s surface to remove imperfections, oxidation, and scratches.

Brightening:

After the initial polishing, the machine uses a finer polishing compound or buffing wheel to brighten the surface and achieve a mirror-like finish. The machine may use multiple polishing stages to refine the surface, ensuring a consistent and high-quality finish.

Inspection and Adjustment:

Once the polishing cycle is complete, the finished products are inspected for quality. If necessary, the CNC program can be adjusted to refine the finish or target specific areas for further polishing.

Cleaning and Packaging:

Benefits

Consistency: CNC-controlled polishing ensures that every product is finished to the same high standard, minimizing quality variation across batches.

Efficiency: Automated polishing reduces the time and labor required to finish each product, increasing production speed and reducing costs.

Customization: The machine can be programmed for a variety of products, shapes, and finishes, allowing manufacturers to produce a wide range of faucets and sanitary hardware.

Reduced Material Waste: With precise control over polishing pressure and speed, the machine minimizes material waste and extends the lifespan of abrasive materials.

Conclusion

The CNC Metal Polishing Machine for polishing and brightening basin faucets, kitchen faucets, bath faucets, and other sanitary ware is an essential tool for modern faucet manufacturers. With its high precision, automated functionality, and ability to handle a wide range of materials and finishes, this machine is the ideal solution for producing aesthetically superior and durable metal sanitary products. Its ability to consistently deliver high-quality finishes while improving production efficiency makes it a valuable asset for businesses looking to meet market demands while maintaining cost-effectiveness.