10-axis, 2500mm CNC sheet metal folding machine is an advanced piece of equipment designed for precise bending and folding operations in sheet metal fabrication.

Specifications

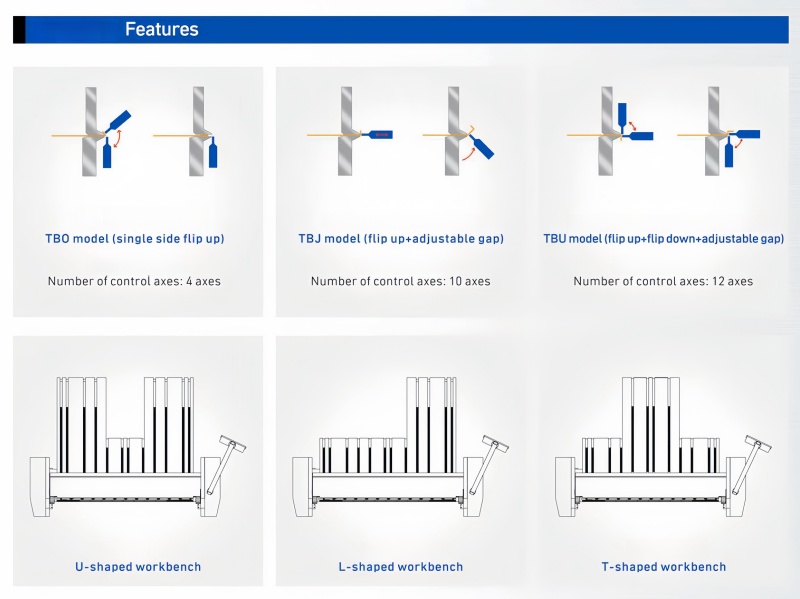

Axes: 10 axes, allowing for complex and precise bending profiles.

Working Width: 2500 mm, suitable for larger sheets of metal.

Bending Capacity: Typically capable of handling materials up to a certain thickness, often around 1.0 to 6.0 mm, depending on the material type (e.g., stainless steel, aluminum).

Bending Angle: Capable of bending angles up to 180 degrees, with programmable angles for various operations.

Back Gauge: CNC-controlled back gauge for precise positioning of the workpiece.

Tooling: Quick-change tooling system to accommodate various bending shapes and angles.

Power Source: Hydraulic or electric drive system for consistent performance.

Control System: Advanced CNC control with a user-friendly interface, programmable for multiple operations.

Safety Features: Emergency stops, safety guards, and other features to ensure operator safety.

Key Features

High Precision:

Versatility:

User-Friendly Interface:

Automatic Adjustments:

Durable Construction:

Real-Time Monitoring:

Compact Design:

Applications

This type of CNC folding machine is commonly used in industries such as:

Automotive: For producing parts like brackets, frames, and enclosures.

Aerospace: Manufacturing components that require high precision and quality.

HVAC: Creating ductwork and other components.

Metal Fabrication Shops: General-purpose bending and folding for custom projects.

Electronics: Producing enclosures and mounts for electronic devices.

Recommended Brands

When considering a 10-axis, 2500mm CNC sheet metal folding machine, look for reputable manufacturers such as:

Amada

Trumpf

Bystronic

EHT

LVD

Technical Parameter

| Item | Unit | TB025 | TB032 | TB041 | TBJ25 | TBJ32 | TBJ41 | TBU25 | TBU32 | TBU41 |

| Bending thickness (carbon steel) | mm | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Bending thickness (stainless steel) | mm | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Bending angle range | degrees | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | -45...+45 | -45...+45 | -45...+45 |

| Max. bending length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Rear positioning length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Open height | mm | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Bending tool height | mm | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 |

| Control axis number |

| 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Pressing speed | mm/s | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Bending speed | m/s | 5.0 | 5.0 | 5.0 | 6.5 | 6.5 | 6.5 | 7.0 | 7.0 | 7.0 |

| Motor energy consumption | kW | 3.5 | 4.5 | 6.1 | 3.5 | 4.5 | 6.1 | 5.5 | 7.0 | 10.0 |

| External dimensions (L × W × H) | mm | 3100×1650 | 3800×1950 | 5300×2150 | 3100×1650 | 3800×1950 | 5300×2150 | 3100×1650 | 3800×1950 | 5700×2150 |

| Weight | kg | 4500 | 5300 | 7500 | 4500 | 5300 | 7500 | 4900 | 7000 | 11000 |

This table provides information on various models of CNC sheet metal folding machines, highlighting their specifications such as bending thickness, bending angle range, maximum bending length, open height, speed, motor energy consumption, dimensions, and weight.

Recommended Models:

Some well-regarded brands that manufacture high-quality CNC sheet metal folding machines include:

Amada: Known for advanced technology and high-quality machines suitable for various bending applications.

Trumpf: Offers innovative solutions and robust machines for efficient sheet metal processing.

Bystronic: Features user-friendly interfaces and reliable performance for bending and folding tasks.

EHT: Provides a range of CNC folding machines with customizable features to meet specific production needs.

Applications:

CNC folding machines are widely used in industries such as:

Automotive manufacturing

Aerospace components

HVAC systems

Electrical enclosures

Furniture manufacturing