1. Main Processing Range of the Equipment

Carbon Steel Plates, Steel Hammer Disc Brush, Sanding Belt, and Deburring Equipment: A Comprehensive Solution for Metal Surface Processing

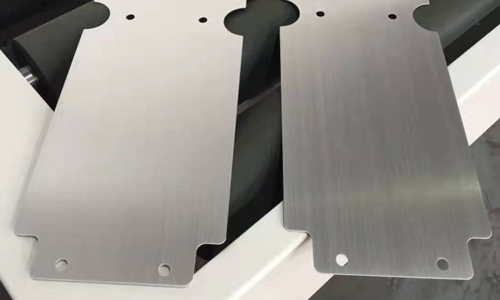

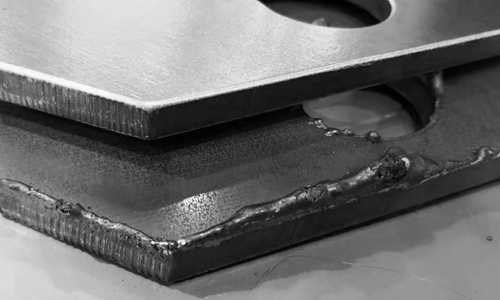

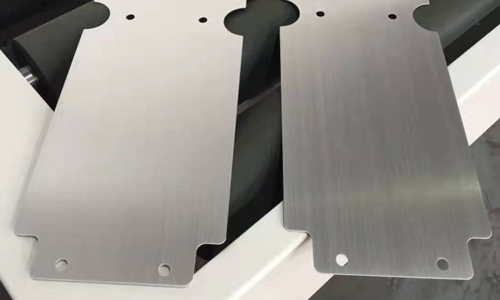

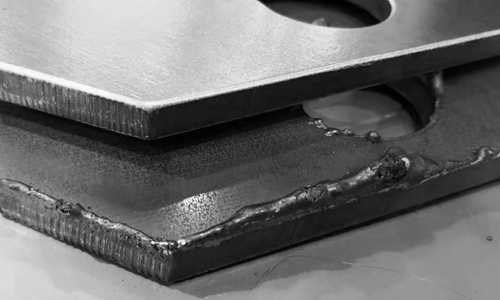

Carbon steel plates are widely used in industries such as construction, automotive, and manufacturing due to their durability, strength, and versatility. However, during the cutting and processing stages, burrs, slag, and rough edges can form, which may affect the quality and precision of the final product. To address these issues, effective deburring solutions are essential.

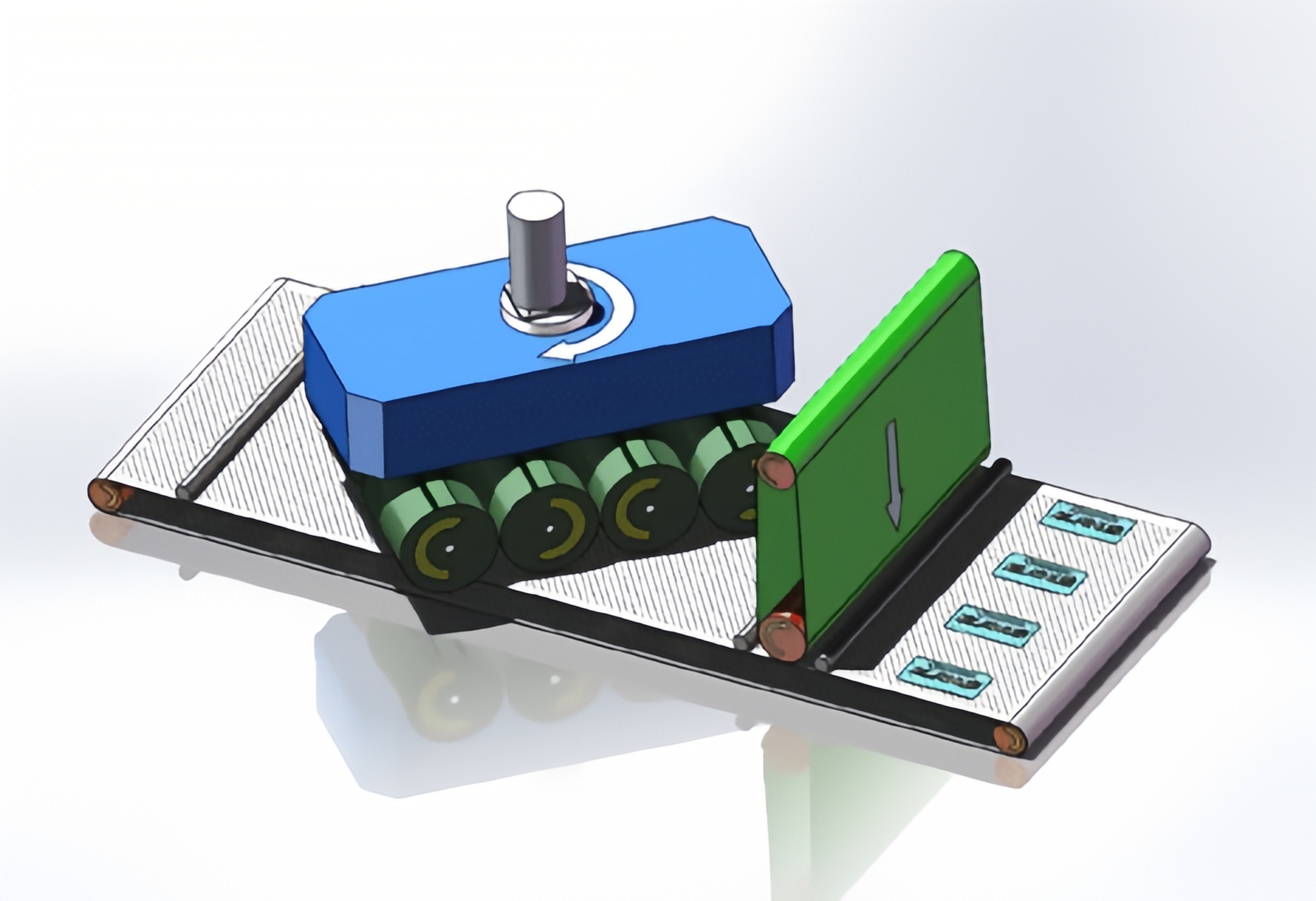

Steel Hammer Disc Brush: A key tool for deburring carbon steel plates, the steel hammer disc brush is designed to remove stubborn slag and burrs from the edges and surface of metal parts. The rotating disc brushes use high-impact forces to knock off slag particles, ensuring a clean, smooth surface without damaging the underlying material. These brushes are particularly effective for removing burrs created by processes such as plasma, oxyfuel, and laser cutting.

Sanding Belt: After the steel hammer disc brush treatment, the sanding belt further refines the metal surface, ensuring that any remaining burrs and surface imperfections are polished away. Made from high-quality abrasive materials, sanding belts are available in various grit sizes to suit different processing requirements. They are ideal for smoothing rough edges and achieving a uniform surface finish across the entire workpiece.

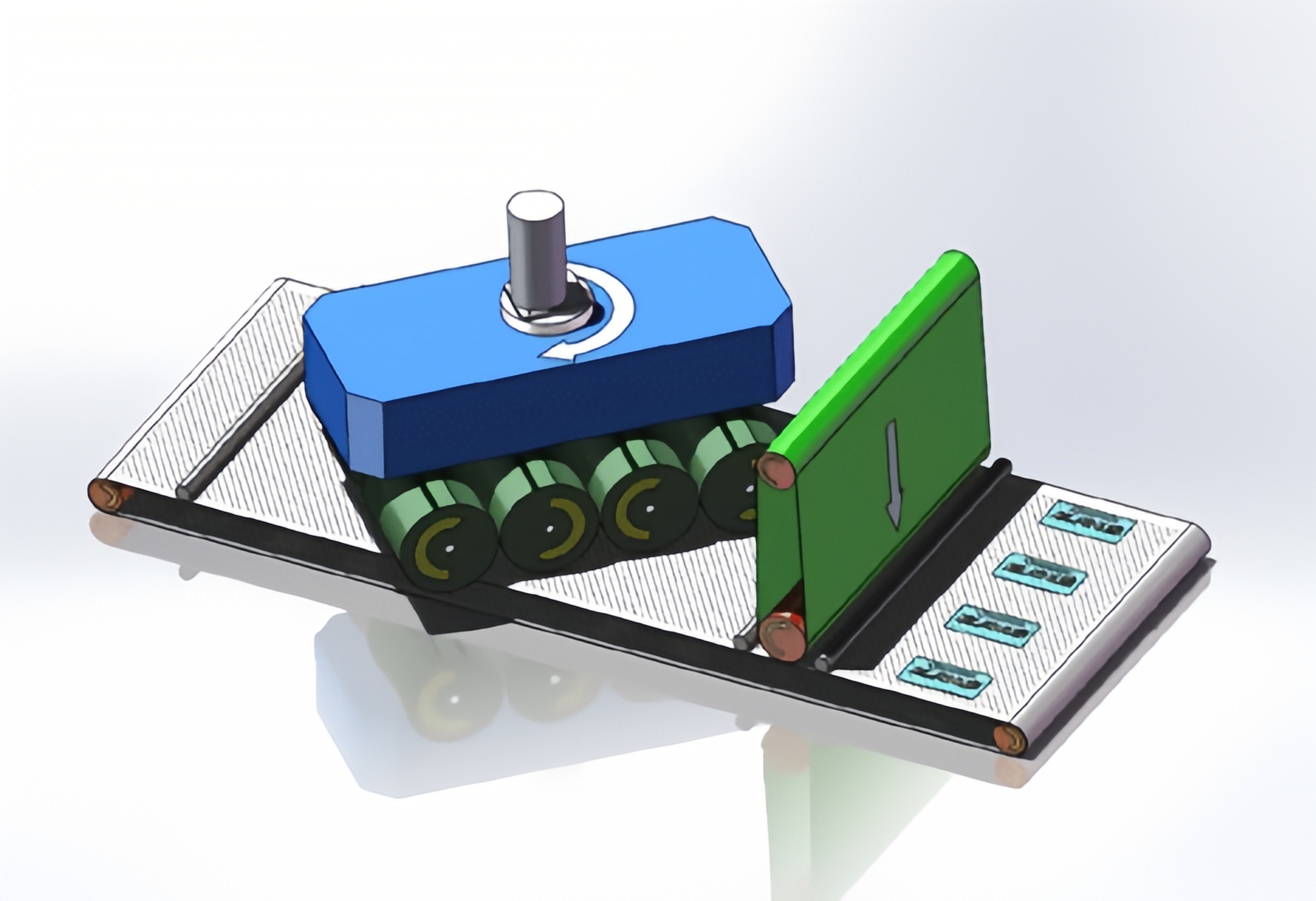

Deburring Equipment: Modern deburring machines combine multiple technologies, such as steel hammer disc brushes, sanding belts, and planetary roller brushes, to perform edge rounding, deburring, and surface finishing in a single pass. These machines ensure consistent quality and precision, removing burrs and rounding edges to specified radii, all while maintaining the workpiece's dimensional accuracy.

Main Technical Parameters of the Equipment:

Processing Width: ≤800mm

Processing Thickness: 0.5~80mm

Minimum Workpiece Size: 50mm x 50mm (Carbon steel)

Total Power: 20.25kW

Steel Hammer Disc Brush Size: Φ162mm

Sanding Belt Size (60# Zirc-Alumina): Φ3530mm x 80mm

Sanding Roller Brush Size (120# Abrasive, Germany Künzle & Tasin): Φ300mm x 300mm

Conveyor Feed Speed: 0.5~6m/min (Variable Frequency Control)

Sanding Belt Line Speed: 12m/s

Roller Brush Self-Rotation Speed: 8~26m/s (Variable Frequency Control)

Roller Brush Orbital Speed: 1~15r/min (Variable Frequency Control)

Number of Roller Brush Planetary Axles: 1

Number of Roller Brush Self-Rotation Axles: 4

Processing Thickness Servo Adjustment Precision: 0.01mm

Roller Brush Compensation Servo Adjustment Precision: 0.01mm

Grinding Consumables: Steel hammer disc brushes + sanding belts + roller brushes

Conveyor Worktable Load Capacity: ≤400kg

Dust Collection Airflow: 5000m³/h

Machine Dimensions: Length 4100mm x Width 1900mm x Height 2200mm

Machine Weight: Approximately 3 tons

Consumables List:

| Item Name | Specifications/Model | Quantity | Estimated Service Life |

| Rubber Conveyor Belt | Φ8600mm x 800mm | 1 piece | 6000-20000 hours |

| Sanding Belt Backing | Φ3340mm x 80mm | 1 piece | 300-1000 hours |

| Grinding Graphite Pads | 70×30×10mm | 30 pieces | 300-1000 hours |

| Steel Hammer Disc Brush | Φ162mm | 6 pieces | 3000-10000 hours |

| Zirconia Alumina Sanding Belt | Φ3530mm x 80mm | 1 piece | 8-40 hours |

| Universal Roller Brushes | Φ300mm x 400mm | 4 pieces | 1000-3000 hours |

Installation Requirements:

Sufficient horizontal installation space (4m x 5m).

380V, 50Hz power supply (±10%).

Clean compressed air supply.

Documentation Included (2 copies of the user manual):

Mechanical schematic diagram.

Electrical schematic diagram.