Insert Grinding Machine MK-400PLUS

Fully Automatic 5-Axis Complex Insert Grinder for Carbide, Cermet, Ceramic, CBN, and PCD Inserts

The MK-400PLUS is a next-generation 5-axis CNC Insert Grinding Machine designed for the high-precision, fully automated production of indexable inserts, especially those requiring complex periphery geometries and dual K-land chamfers. This high-end grinder is equipped with state-of-the-art motion control, robotic automation, and flexible software, making it capable of machining 3D profiles and insert shapes that conventional machines simply cannot handle.

Whether you manufacture standard ISO inserts or custom-shaped cutting tools, the MK-400PLUS offers unmatched versatility, consistency, and efficiency for your modern tool production line.

✅ Key Application Capabilities

The MK-400PLUS is developed to meet advanced industry needs with three core use cases:

Fully automatic machining of insert peripheries with high dimensional accuracy.

Simultaneous double K-land chamfering, eliminating secondary operations.

3D contour grinding for special inserts with complex geometries — including multi-radius and asymmetric shapes used in aerospace, mold, and high-precision automotive parts machining.

This enables tool manufacturers and resharpening centers to achieve high throughput, perfect repeatability, and minimum human intervention, reducing cost per part.

️ Technical Overview

➤ Supported Materials

Carbide: For general metal cutting and wear resistance.

Cermet: For high-speed finishing with minimal built-up edge.

Ceramics: For heat-resistant machining in cast iron and superalloys.

CBN (Cubic Boron Nitride): For hardened steels and dry cutting.

PCD (Polycrystalline Diamond): For non-ferrous and composite materials.

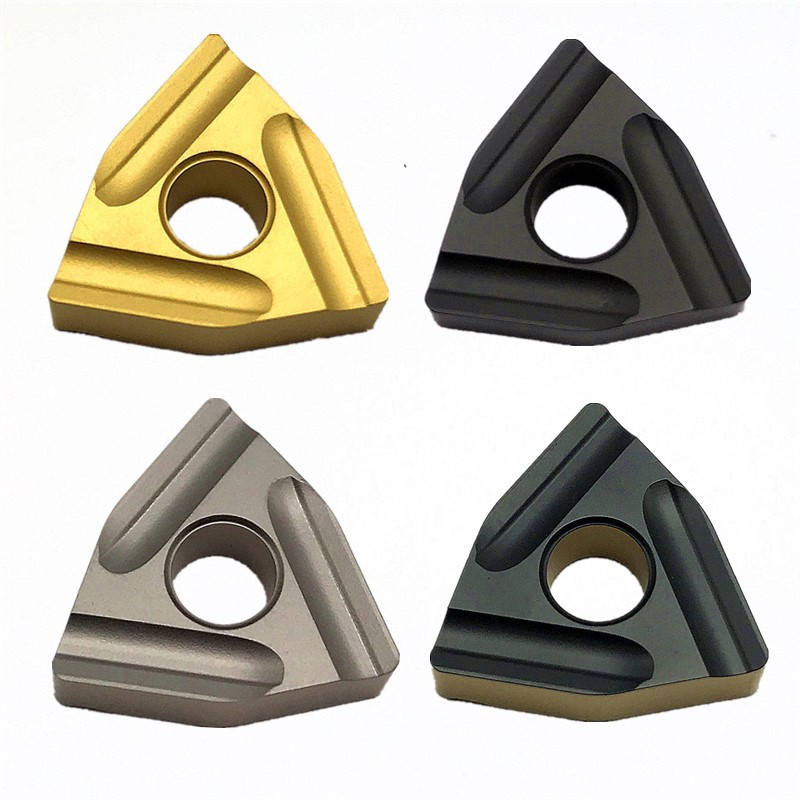

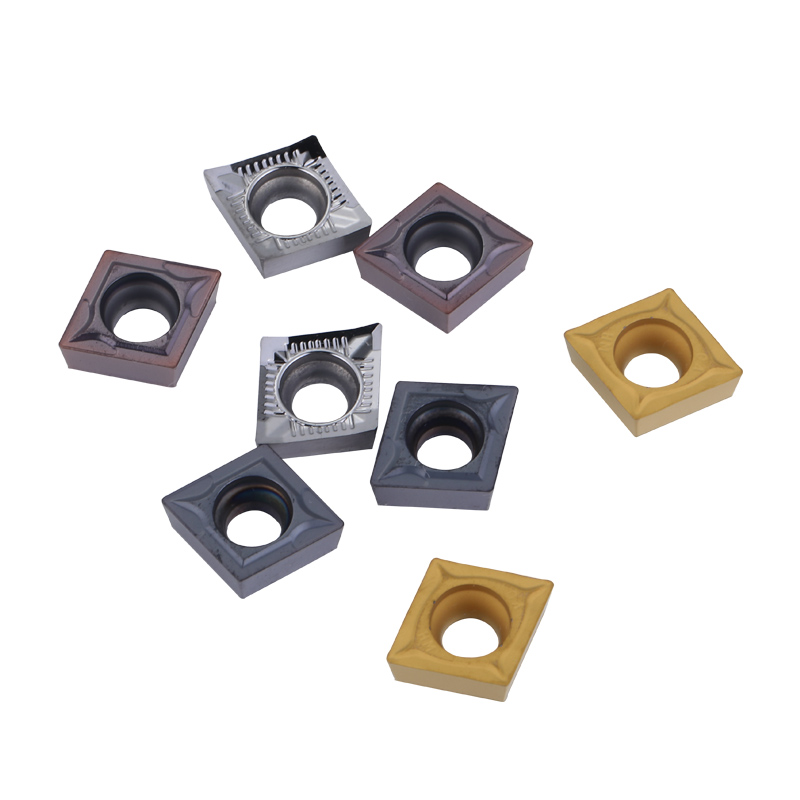

➤ Supported Insert Shapes

ISO-standard inserts: CNMG, TNMG, SNMG, WNMG, etc.

Custom non-standard profiles

Asymmetric 3D tool geometries

Round, square, rhombic, and triangle inserts

⚙️ Structural & Motion Architecture

The MK-400PLUS features 5-axis simultaneous control enabling flexible, precise, and smooth grinding across complex geometries.

| Axis | Function |

| X-Axis | Left-right oscillation with automatic lubrication on precision guide rails |

| Y-Axis | Feed axis with direct-drive and centralized lubrication |

| A-Axis | Insert rotation; 36 mm blade seat projection length |

| C-Axis | Tilt adjustment for grinding table: -90° to +90° (Travel -91° to +91°) |

| V-Axis | In-process grinding wheel cleaning system |

| W-Axis | Manual positioning of core shaft (Z-direction support, vertical adjustment) |

The grinding spindle is powered by a 7.5 kW flange-type 3-phase induction motor (V3 vibration level), ensuring stable cutting forces and long grinding wheel life. Additionally, a 1.5 kW electric spindle powers the wheel dressing unit, providing real-time wheel profiling for consistent results.

Automation Features

➤ Robotic Material Handling

Equipped with a 3-axis robotic arm, the MK-400PLUS automates insert loading and unloading, tray movement, and positional handling with:

B1 Axis – Horizontal tray transport

B2 Axis – Tray pushing/pulling

B3 Axis – Vertical motion

➤ Material Tray System

2 × Standard Tray: 350 mm x 350 mm

2 × T-type Tray: 190 mm x 370 mm

One robotic gripper unit for reliable insert pickup & placement

➤ Integrated Detection System

Pre-grinding inspection: Measures blank dimensions and verifies alignment.

Post-grinding inspection: Confirms inscribed circle and feature accuracy.

Automatically rejects defective pieces, triggers regrinding, or corrects the next cycle based on deviations.

This closed-loop detection system significantly enhances yield and quality control — ideal for high-precision, high-value insert production.

CNC System and Software

The MK-400PLUS uses a powerful, non-PC-based CNC controller tailored for 5-axis insert grinding. It supports:

Up to 9 simultaneously controlled axes

Graphical programming interface for easy tool profile input

Flexible macros for ISO, custom, and asymmetric inserts

Automatic compensation, real-time correction, and tool wear tracking

This results in:

Cooling & Cleaning

Main grinding area is protected with a fully enclosed guard and equipped with high-efficiency coolant filtration.

V-Axis online cleaning ensures the grinding wheel stays sharp and free from debris.

Optional offline dressing device available for continuous wheel shape maintenance.

⚡ Utilities & Footprint

| Specification | Details |

| Power Supply | 25 kVA / AC 380V / 50–60 Hz |

| Compressed Air | ≥ 0.5 MPa / 250 N/min |

| Hydraulic Pressure System | Max Pressure: 7 MPa |

| Machine Dimensions (W×D×H) | 2,475 mm × 2,250 mm × 2,160 mm |

| Machine Weight | 5,500 kg |

Why Choose MK-400PLUS

| Feature | Benefit |

| 5-axis CNC with robotic automation | Full automation and lights-out production capability |

| Complex 3D shape grinding | Ideal for advanced tool geometries and multi-radius contours |

| Material versatility | Processes carbide, cermet, ceramics, CBN, and PCD with precision |

| Fast cycle times | Reduce production lead time and increase throughput |

| In-process detection system | Ensures tight tolerance and reduces scrap rate |

| High spindle power & wheel size | Handles tough materials and large removal rates with Ø400 mm wheel |

| Scalable tray system | Supports small-batch and large-volume insert production |

Industries Served

Aerospace: Complex profile inserts for titanium and high-temp alloys

Automotive: Precision finishing tools for engine and drivetrain parts

Mold & Die: High-accuracy radius and form inserts

Cutting Tool OEMs: Mass production of standard and custom inserts

Resharpening Services: Regrinding and recovery of worn tools

Conclusion

The MK-400PLUS redefines insert grinding through a blend of mechanical precision, advanced automation, and material versatility. Whether you're machining standard ISO inserts or intricate 3D profiles from ultra-hard materials like PCD or CBN, this machine delivers repeatable, high-accuracy results — every time.

From efficient batch production to custom insert regrinding, the MK-400PLUS helps manufacturers increase productivity, reduce operational costs, and raise quality standards.

If your business demands next-generation insert production, the MK-400PLUS is the solution.