400mm Wet Wide Belt Sander – RRR5340

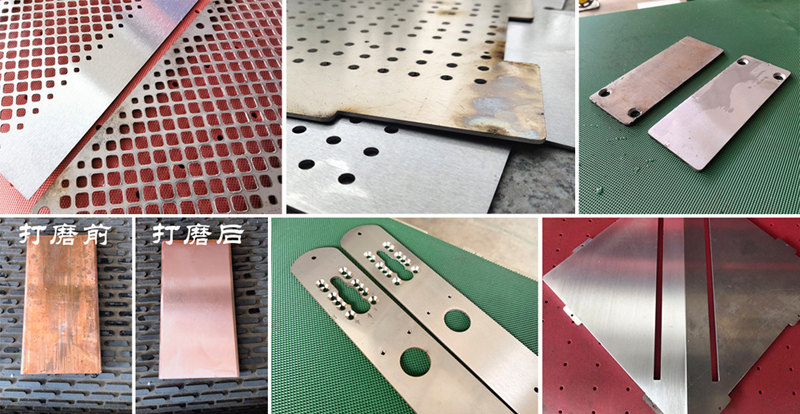

High-Precision Deburring, Edge Rounding, and Surface Finishing for Laser-Cut & Stamped Sheet Metal

The RRR5340 400mm Wet Wide Belt Sander is a high-performance machine designed for deburring, edge rounding, and surface finishing of laser-cut and stamped sheet metal. Featuring three working stations, each equipped with an individual sanding belt, this machine ensures uniform material removal and a smooth, high-quality finish. The wet sanding process minimizes heat buildup and reduces dust, making it ideal for stainless steel, aluminum, and carbon steel applications.

This model is available with two configurations:

Magnetic Conveyor Worktable – Ideal for handling small and thin metal parts, ensuring strong hold-down during sanding.

Non-Magnetic Conveyor Worktable – Suitable for standard sheet metal processing, offering flexibility for various materials.

Features & Applications

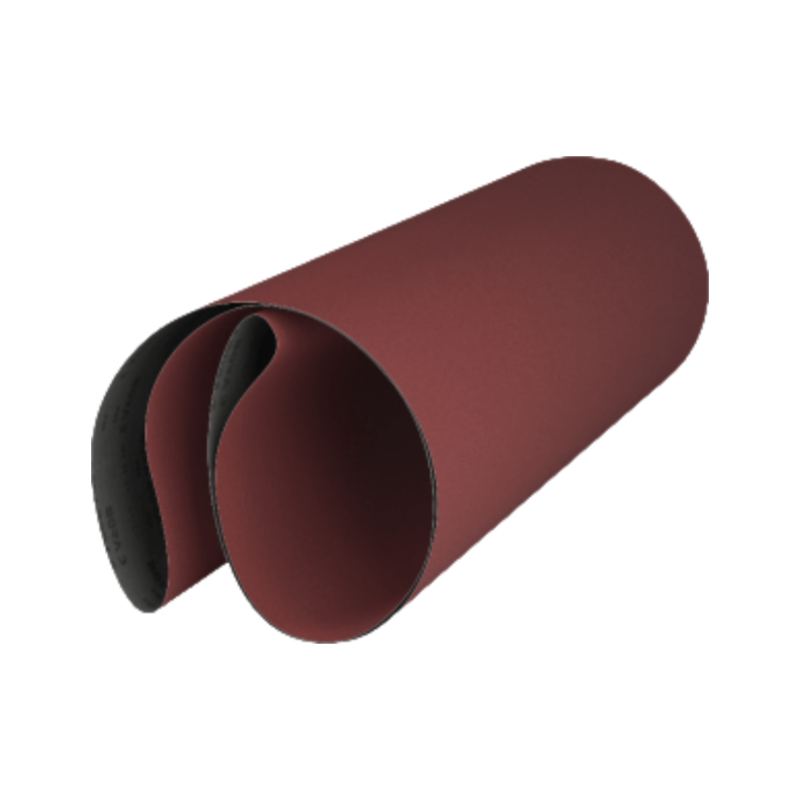

Three Sanding Stations: Each station is equipped with a separate abrasive belt, providing sequential processing for consistent surface quality.

High-Efficiency Deburring: Removes sharp burrs and rough edges from laser-cut, stamped, and plasma-cut metal parts.

Edge Rounding & Finishing: Ensures smooth, rounded edges to enhance safety, coating adhesion, and part quality.

Wet Sanding Technology: Prevents overheating, reduces dust, and extends abrasive belt life.

Versatile Material Compatibility: Works with stainless steel, carbon steel, aluminum, and non-ferrous metals.

Adjustable Feed Rate: Enables customized processing for different materials and thicknesses.

Magnetic vs. Non-Magnetic Conveyor: Choose between a magnetic worktable for secure handling of small parts or a non-magnetic conveyor for general applications.

Compact & Sturdy Design: Ensures durability and reliability in industrial applications.

Technical Specifications

| Parameter | Unit | RRR5340 |

|---|---|---|

| Max Working Width | mm | 400 |

| Max Working Height | mm | 60 |

| Min Working Length | mm | 150 |

| 1st Sanding Belt Power | kW | 7.5 |

| 2nd Sanding Belt Power | kW | 5.5 |

| 3rd Sanding Belt Power | kW | 5.5 |

| Polishing Wheel Power | kW | / |

| Rotary Motor Power | kW | / |

| Feed Motor Power | kW | 1.5 |

| Lifting Motor Power | kW | 0.37 |

| Oscillating Motor Power | kW | / |

| Vacuum Motor Power | kW | / |

| Machine Dimensions | m | 2.4 × 1.5 × 1.8 |

| Machine Weight | kg | 1500 |

| Abrasive Belt Size | mm | 1520 × 400 |

| Worktable Options | - | Magnetic Conveyor / Non-Magnetic Conveyor |

Applications

The RRR5340 Wet Wide Belt Sander is ideal for industries requiring precision surface finishing, deburring, and edge rounding of sheet metal components. It is widely used in:

Laser-cutting workshops – To remove burrs and improve edge quality.

Metal stamping factories – To deburr and finish stamped metal parts.

Aerospace & automotive industries – To achieve high-quality, uniform surface treatment.

Stainless steel & aluminum processing plants – For wet sanding without overheating or warping.

Precision fabrication – Ensures smooth, defect-free surfaces before coating or welding.