Industrial die cutting machines are used to cut, shape, or form materials into specific patterns or designs using a die. They are commonly employed in various industries such as packaging, automotive, textiles, and more.

Types of Die Cutting Machines

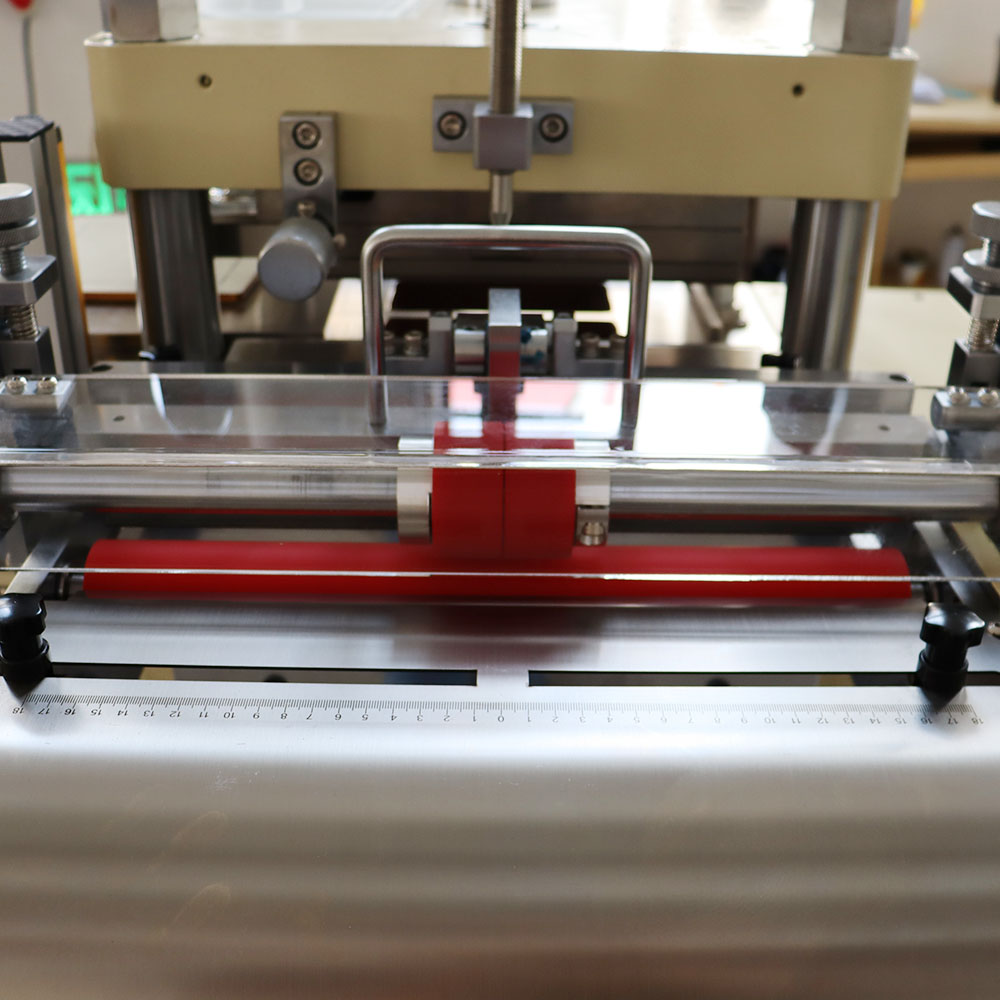

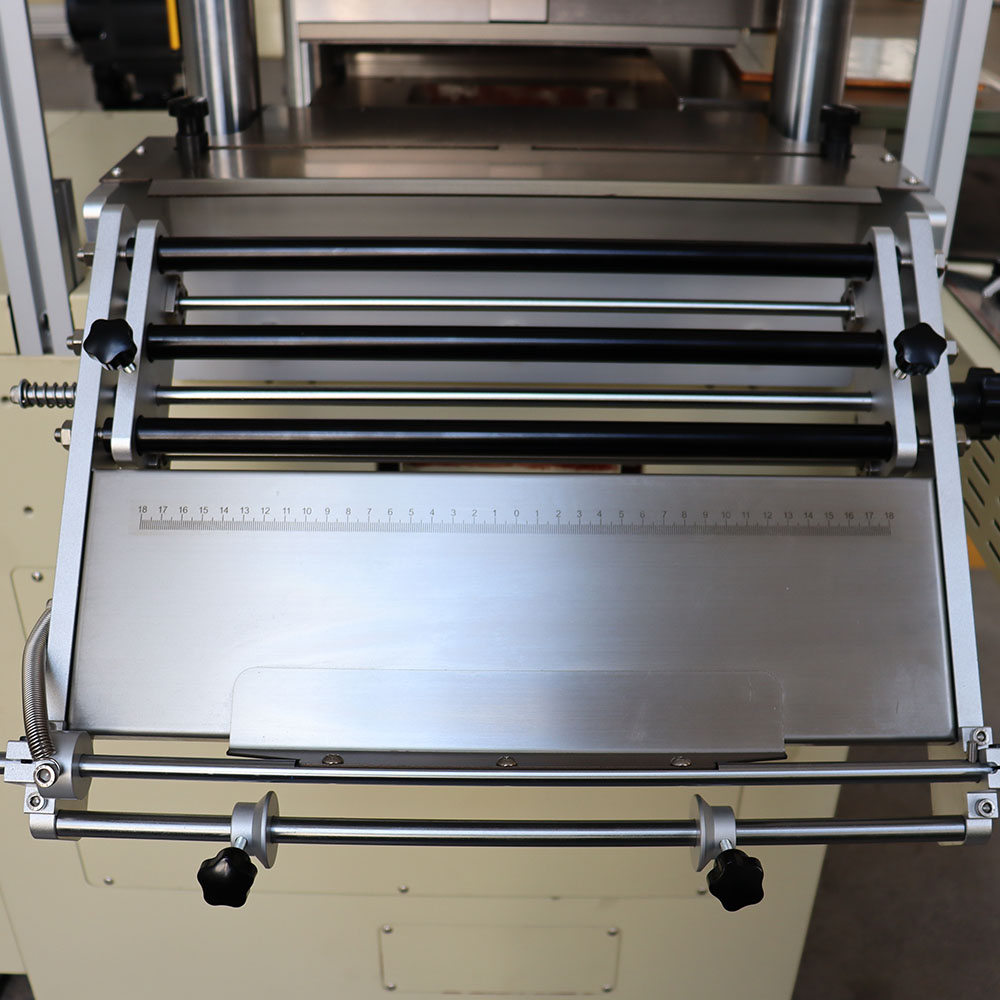

Rotary Die Cutters:

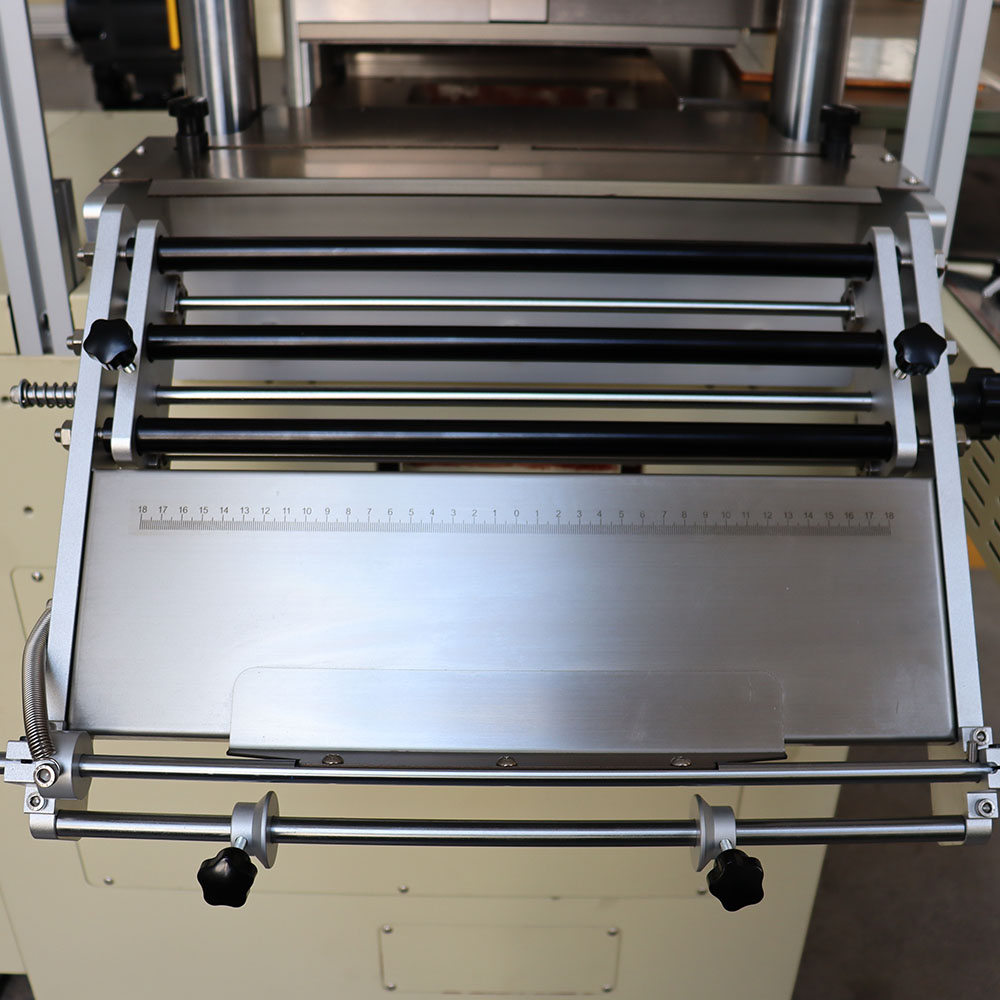

Function: Uses rotary dies to cut materials as they pass through the machine. Ideal for high-speed and high-volume production.

Applications: Labels, flexible packaging, and continuous roll-fed materials.

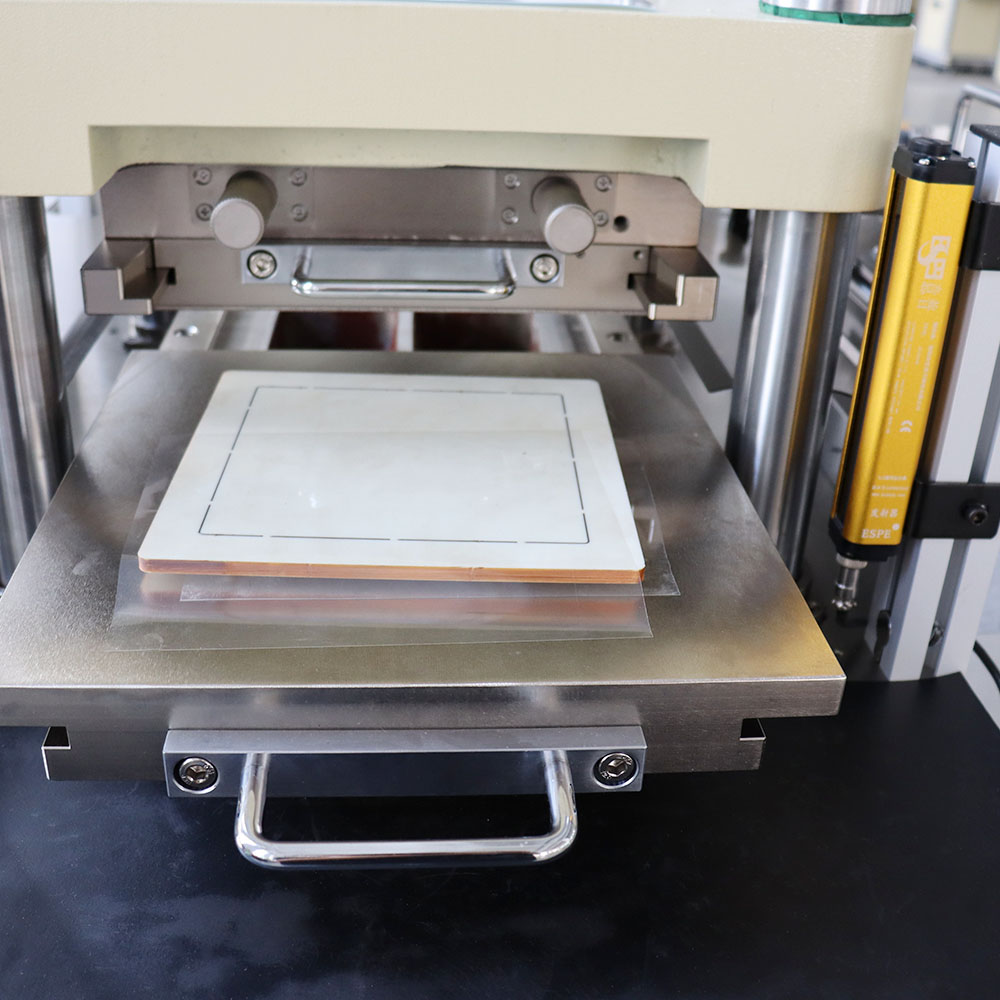

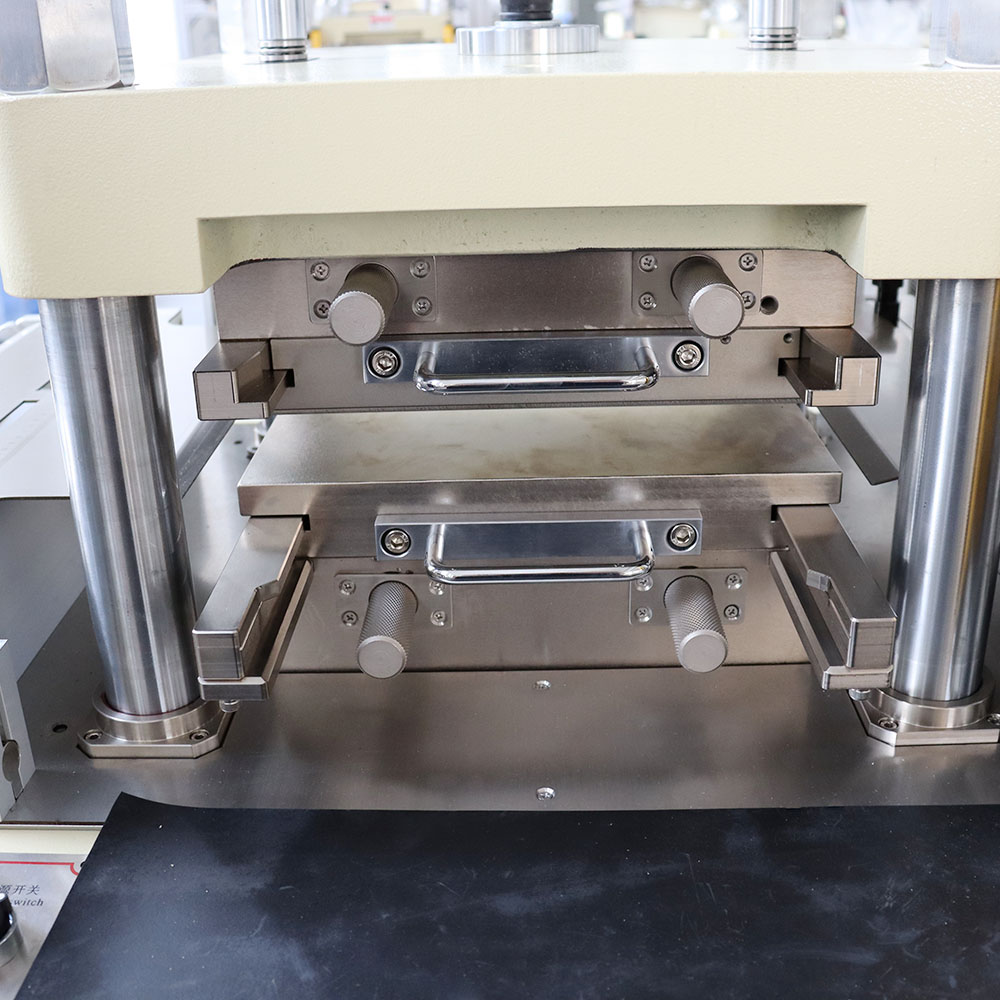

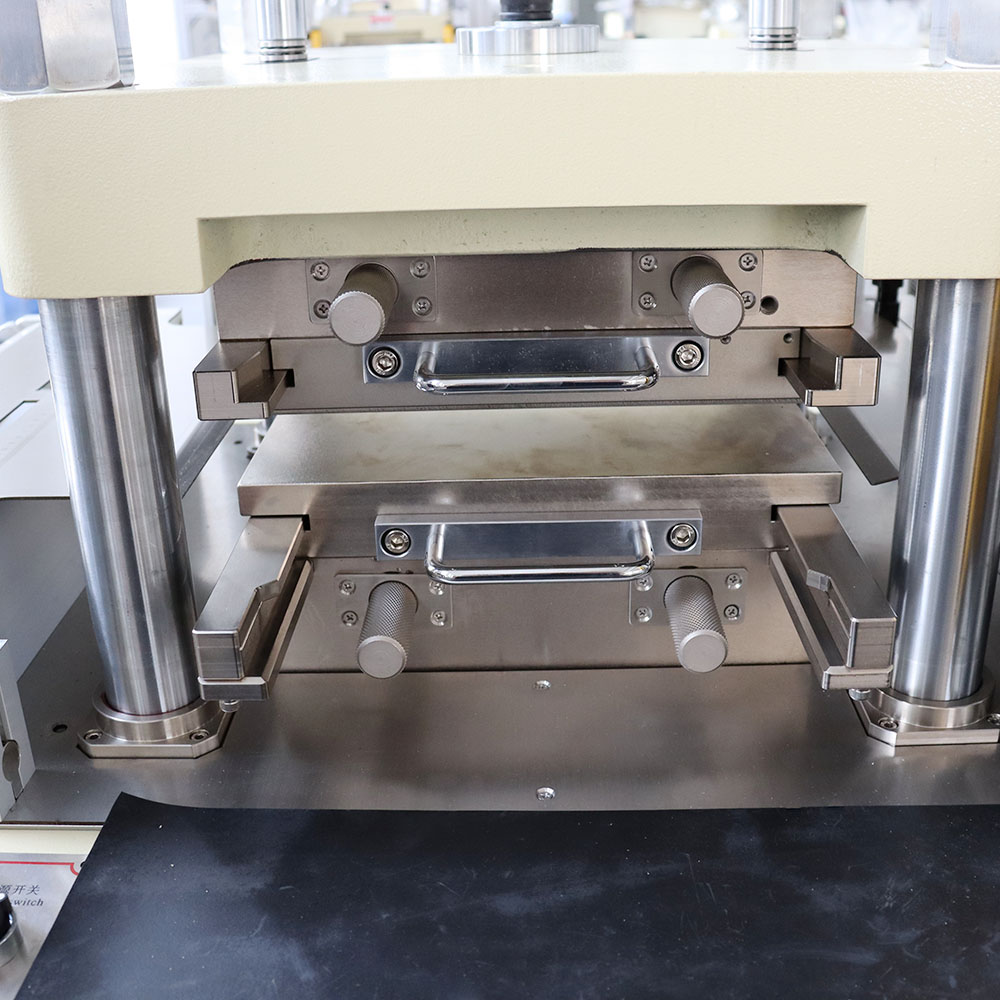

Flatbed Die Cutters:

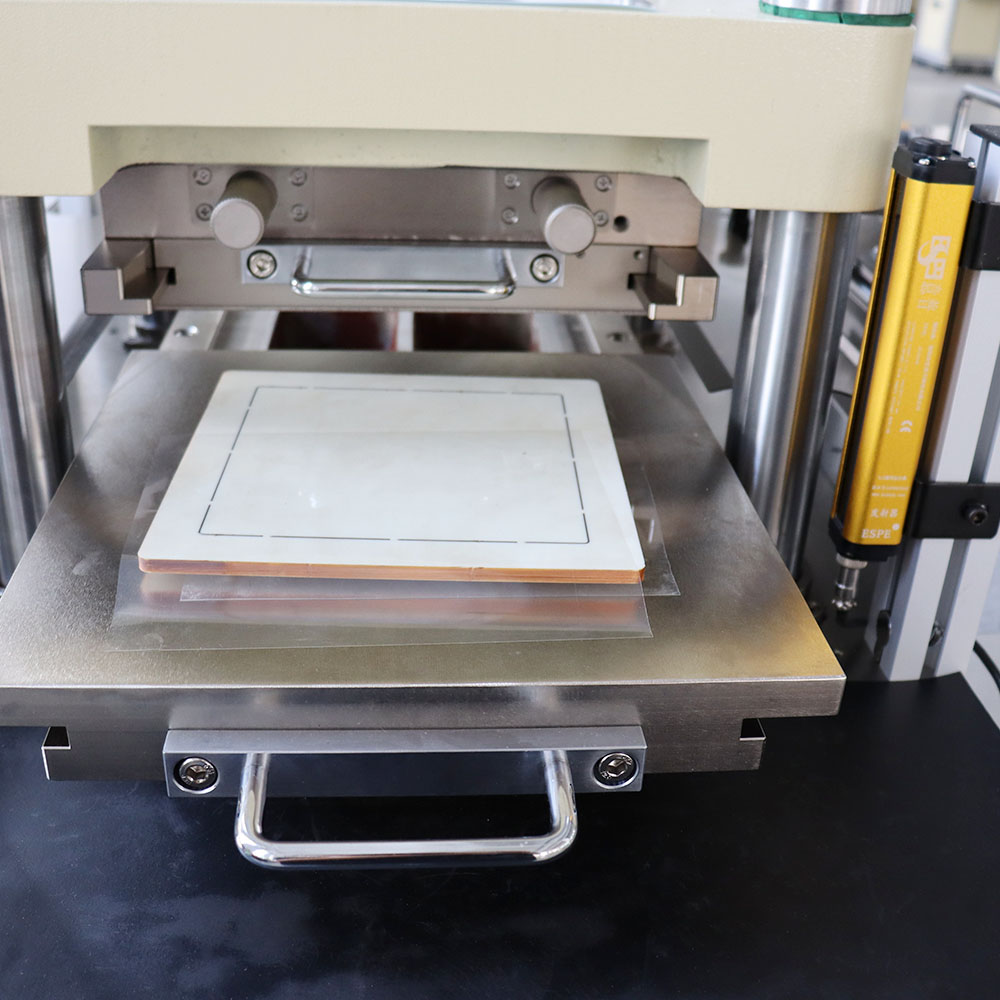

Function: Employs a flat die that presses down onto the material to cut it. Suitable for various material sizes and thicknesses.

Applications: Cardboard, paperboard, and thicker materials for packaging and displays.

Strip Die Cutters:

Blanks Die Cutters:

Function: Cuts individual shapes or blanks from material sheets. Typically used for producing small parts or components.

Applications: Automotive parts, electronics, and consumer goods.

Digital Die Cutters:

Function: Uses computer-controlled blades to cut materials according to digital designs. Offers flexibility and quick setup changes.

Applications: Custom and small-batch production, prototyping.

Key Features

Precision: Ensures accurate and consistent cuts, critical for maintaining product quality and performance.

Speed: High-speed capabilities for efficient mass production.

Material Compatibility: Capable of cutting various materials including paper, cardboard, plastics, textiles, and metals.

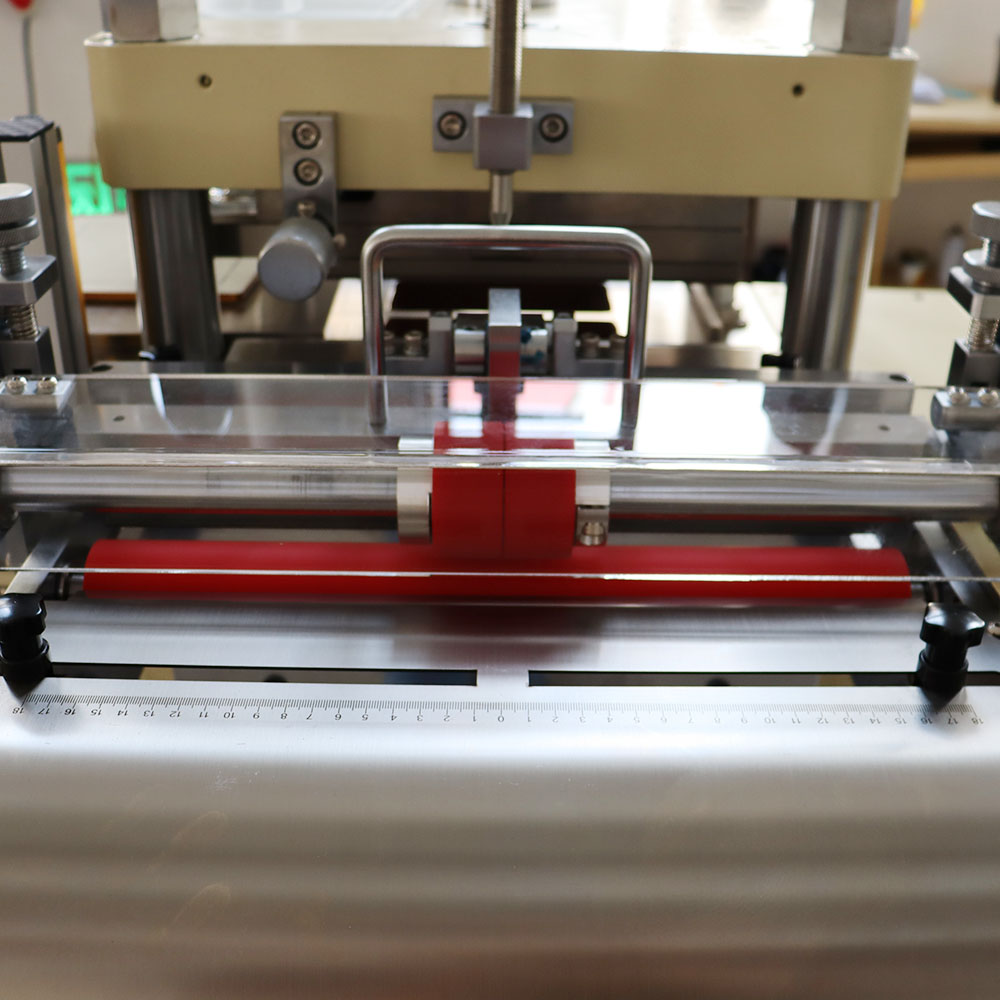

Adjustability: Allows for different die sizes and shapes, as well as adjustments for material thickness and cut depth.

Automation: Advanced models include automated feeding, cutting, and stacking systems for increased efficiency.

Safety Features: Includes guards and emergency stop functions to protect operators.

Applications

Packaging: Creating boxes, cartons, and other packaging materials.

Automotive: Cutting components for interior and exterior parts.

Textiles: Producing patterns and components for garments and upholstery.

Electronics: Cutting insulation, gaskets, and other electronic components.

Technical Specifications:

| Specifications | JT-F300 | JT-F350 | JT-F450 |

| Feed Width | 310 mm | 370mm | 470mm |

| Max. Die Cutting Area | 300× 310 mm | 350 × 370 mm | 450× 470 mm |

| Max. Operating Speed | 18000 punches/hour | 18000 punches/hour | 12000 punches/hour |

| Punching Stroke | 28 mm | 28 mm | 28 mm |

| Pressure Regulation | 30 mm | 30 mm | 30 mm |

| Voltage Regulation Accuracy | 0.005 mm | 0.005 mm | 0.005 mm |

| Drawing Accuracy | ±0.05 mm | ±0.05 mm | ±0.05 mm |

| Upper Form Size | 300× 310 × 37 mm | 350 × 370× 37 mm | 450 × 470× 37 mm |

| Lower Template Size | 300× 310 × 40.5 mm | 350 × 370×40.5 mm | 350 × 370× 40.5 mm |

| Overall Dimensions | 1850 × 1350 × 1850 mm | 1900 × 1450 × 1850 mm | 2200 × 1450 × 1850 mm |

| Machine Weight | 1200 kg | 1500 kg | 2000 kg |

| Air Source Specification | 0.5–0.7 MPa | 0.5–0.7 MPa | 0.5–0.7 MPa |

| Total Power | 5.5 kW | 7.5 kW | 10.5 kW |

| Lubrication Mode | Intermittent fuel supply | Intermittent fuel supply | Intermittent fuel supply |

| Applicable Die Types | Plywood mold, wood mold | Plywood mold, wood mold | Plywood mold, wood mold |

High-speed die cutting machines are designed for rapid and efficient cutting and processing of materials. They are widely used in various industries such as packaging, printing, automotive, electronics, and more, to meet high-volume production needs. Here’s an overview:

Types of High-Speed Die Cutting Machines

Rotary Die Cutters:

Features: Uses rotary dies to cut materials as they pass through the machine. Ideal for high-speed and high-volume production.

Applications: Labels, flexible packaging, and continuous roll-fed materials.

Flatbed Die Cutters:

Features: Employs a flat die that presses down onto the material to cut it. Suitable for various material sizes and thicknesses.

Applications: Cardboard, paperboard, and thicker materials for packaging and displays.

Strip Die Cutters:

Blank Die Cutters:

Features: Cuts individual shapes or blanks from material sheets. Typically used for producing small parts or components.

Applications: Automotive parts, electronics, and consumer goods.

Digital Die Cutters:

Features: Uses computer-controlled blades to cut materials according to digital designs. Offers flexibility and quick setup changes.

Applications: Custom and small-batch production, prototyping.

Key Features

High Speed: Capable of performing large-scale cutting tasks quickly, enhancing production efficiency.

Precision: Ensures accurate and consistent cuts, which is critical for maintaining product quality.

Automation: Includes automatic feeding, cutting, and stacking systems to improve operational convenience and efficiency.

Material Compatibility: Capable of cutting a variety of materials, including paper, cardboard, plastics, and metals.

Adjustability: Allows for different die sizes and shapes, as well as adjustments for material thickness and cut depth.

Safety: Equipped with protective features to ensure operator safety.

Applications

Packaging: Produces boxes, cartons, and other packaging materials.

Printing: Cuts printed materials and creates detailed designs for various products.

Automotive: Manufactures interior and exterior components, such as gaskets and seals.

Electronics: Cuts insulation, gaskets, and other electronic parts.

Medical: Produces medical packaging, sanitary products, and more.

Maintenance and Care

Regular Inspection: Check dies, blades, and drive systems regularly.

Cleaning: Keep the machine clean to prevent material buildup that can affect cutting performance.

Lubrication: Periodically lubricate moving parts to reduce wear.

Calibration: Regularly calibrate the machine to maintain cutting accuracy.

High-speed die cutting machines are essential for improving production efficiency and product quality. Choosing the right model and configuration can help meet specific production needs. If you have particular requirements or applications, please provide more details for tailored advice.