Laser Cutting Deburring Machine for Sheet Metal

Functionality and Features:

A Laser Cutting Deburring Machine is designed to remove burrs and sharp edges from laser-cut sheet metal parts. The primary purpose of this machine is to clean, smooth, and finish the edges of metal parts after laser cutting, ensuring the components meet the required surface quality standards. This process is especially useful for materials like stainless steel, carbon steel, aluminum, and non-ferrous metals that are prone to burr formation during cutting.

Key Features:

Precise Burr Removal: The laser system effectively removes burrs and oxidized edges without damaging the surface.

Laser Technology: Utilizes high-powered laser beams to precisely remove burrs and smooth edges, resulting in a clean, polished surface.

High Efficiency: Ensures consistent, high-quality deburring without manual intervention, improving productivity and reducing labor costs.

Versatility: Capable of deburring various thicknesses and types of metals, from thin sheets to thicker plates, accommodating different cutting and manufacturing needs.

No Mechanical Contact: As it uses laser beams for deburring, there is no physical contact with the material, reducing the risk of surface scratches or contamination.

Uniform Edge Rounding: Achieves smooth, uniform edge rounding with consistent results, eliminating sharp edges and ensuring safety.

Automation: The machine is automated and can be integrated into an existing production line for seamless operation, increasing throughput and reducing downtime.

Environmentally Friendly: The laser cutting process produces minimal waste and eliminates the need for consumable materials (e.g., abrasive brushes or chemicals), making it an eco-friendly solution.

Process Flow:

Laser Cutting: The initial laser cutting operation creates the desired part shape.

Laser Deburring: The machine uses focused laser beams to melt and vaporize burrs and sharp edges on the workpiece.

Edge Smoothing: The heat from the laser treatment smoothens the edges of the cut, leaving a refined finish without additional manual work.

Inspection and Quality Control: The deburred parts are inspected for quality to ensure that the desired finish and burr removal are achieved.

Output: The final deburred metal part is ready for further processing or assembly.

Applications:

Sheet Metal Fabrication: Ideal for industries such as automotive, aerospace, electronics, and construction, where precise burr removal is essential.

Laser Cutting: For parts that have undergone laser cutting and require a secondary finishing process to remove burrs and oxide layers.

High-Volume Production: Suited for mass production of metal components where high consistency and throughput are needed.

Technical Parameters:

| Parameter | Value |

| Processing Width | ≤ 800mm |

| Processing Thickness | 0.5 - 80mm |

| Minimum Processing Size | 50mm x 50mm (Carbon Steel) |

| Overall Power | 20.25 KW |

| Hammer Disc Brush Size | Φ 162mm |

| Sanding Belt Size | Φ 3530mm x 80mm (60# Zirconia Alumina) |

| Omni-Directional Brush Size | Φ 300mm x 300mm (120# Brush, German Künzeb) |

| Conveyor Speed | 0.5 - 6 m/min (Variable Frequency) |

| Sanding Belt Speed | 12 m/s |

| Roller Brush Rotation Speed | 8 - 26 m/s (Variable Frequency) |

| Roller Brush Planetary Speed | 1 - 15 rpm (Variable Frequency) |

| Roller Brush Axle Heads (Planetary) | 1 (Planetary Rotation) |

| Roller Brush Axle Heads (Self-Rotation) | 4 (Self-Rotation) |

| Thickness Adjustment Precision | 0.01mm |

| Roller Brush Compensation Precision | 0.01mm |

| Grinding Consumables | Sanding Belt + Roller Brush |

| Work Table Load Capacity | ≤ 400kg |

| Dust Extraction Flow | 4000 m³/h |

| Machine Dimensions | Length: 4100mm, Width: 1900mm, Height: 2200mm |

| Machine Weight | Approx. 3T |

Operational Flexibility:

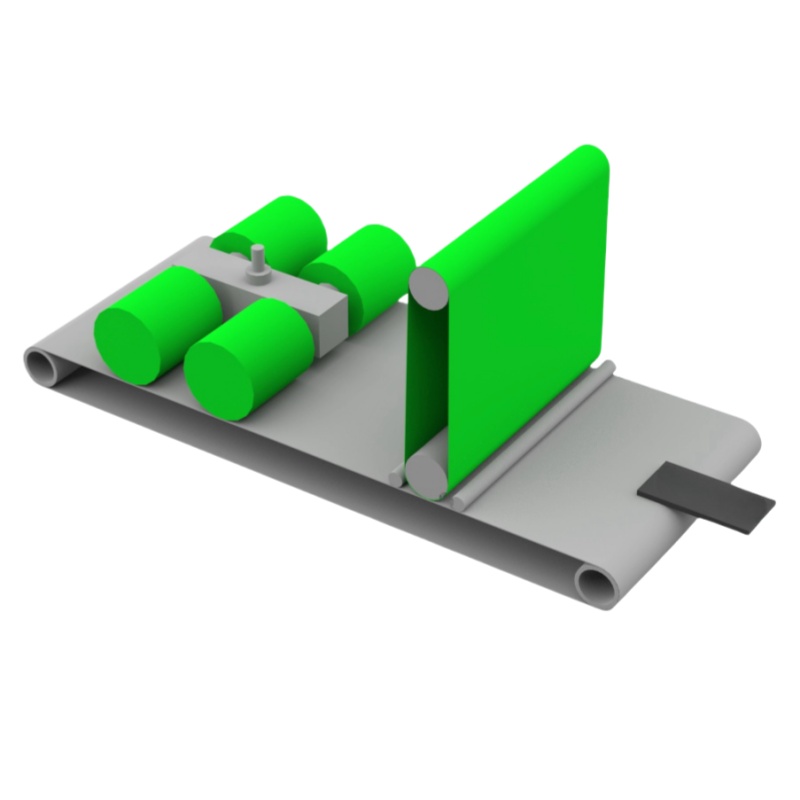

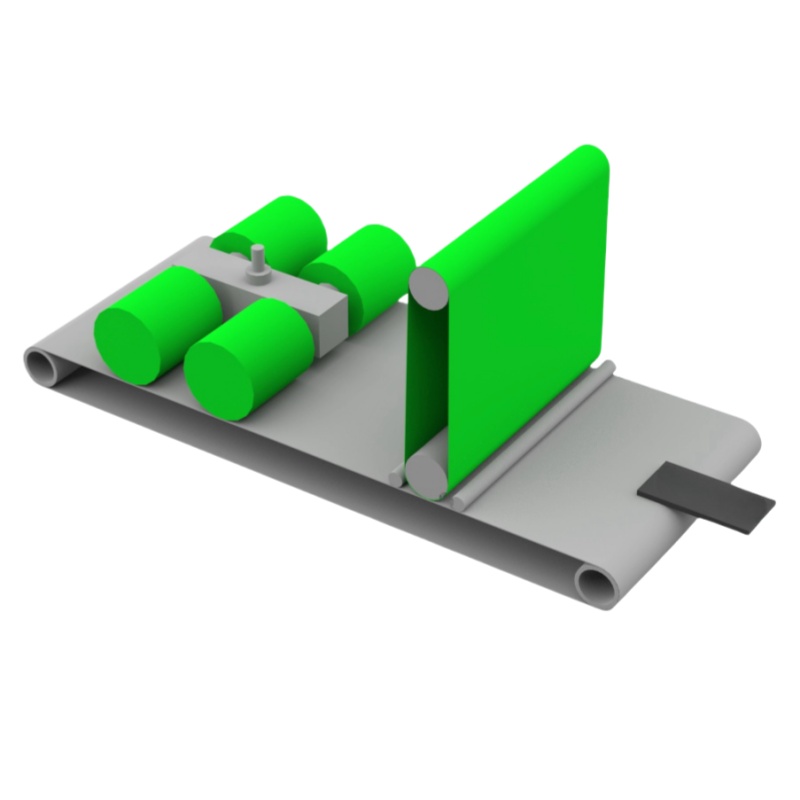

Hammer Disc Brush: Independent operation for removing slag from edges.

Sanding Belt: Can operate independently to achieve brushed finishes, polishing, and deburring on metal surfaces.

Omni-Directional Brush: Independently operates for 360-degree deburring, which is particularly effective for laser-cut, CNC-punched, and coated sheet metal, without damaging any protective film.

Dust Control and Environmental Considerations:

The machine features a wet dust extraction system, which uses a high-pressure fan to collect and filter dust into a water chamber, ensuring that harmful metal particles are captured and safely disposed of. This process helps create a safer, cleaner, and more sustainable work environment while improving air quality and recycling metal dust.

Advantages of the Machine:

Enhanced Efficiency: The continuous feed operation increases the speed and throughput of the processing.

Superior Quality: Consistent and high-quality results that surpass manual processing.

Cost Efficiency: Low operational cost and reduced labor costs when compared to manual deburring.

Safe and Clean Working Environment: Efficient dust collection reduces health risks and improves workplace safety.