LSD-162 Manual Deburring Machine

Advanced Solution for Metal Plate Polishing, Deburring, and Slag Removal

Manual Deburring and Polishing Machine

The LSD-162 Manual Deburring and Polishing Machine is designed for precision finishing, offering a user-friendly, ergonomic design combined with robust performance. Its versatility makes it ideal for metalworking, woodworking, and non-ferrous material processing.

Key Features:

✔ Powerful Motor: 3.86 kW main motor ensures consistent and reliable operation.

✔ Spacious Working Area: 1200 mm × 750 mm platform accommodates a wide variety of workpieces.

✔ Vacuum Suction Table: Securely holds materials during processing without the need for clamps, ensuring efficiency and safety.

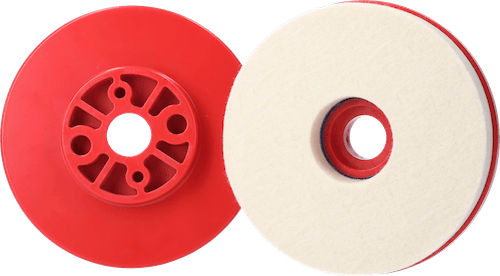

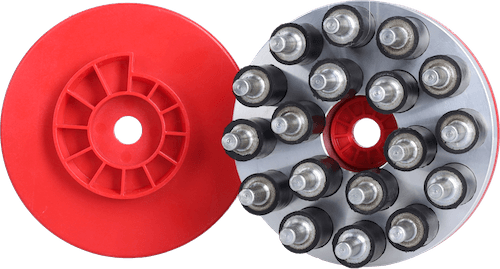

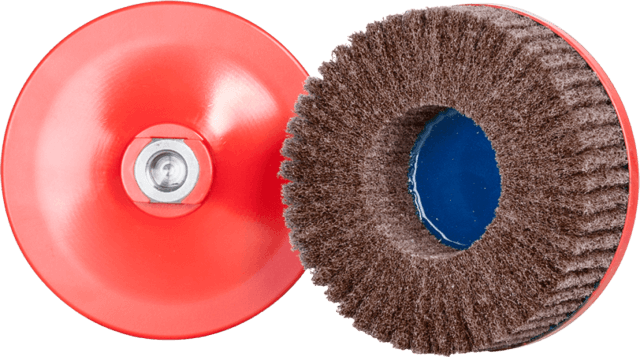

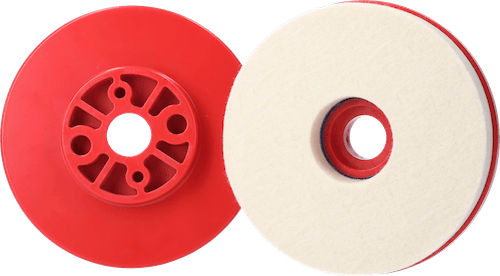

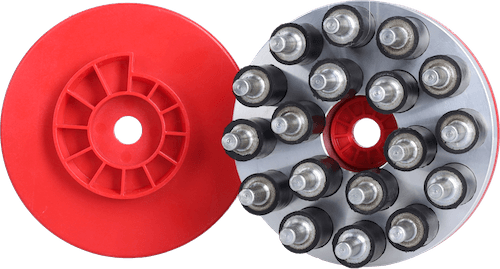

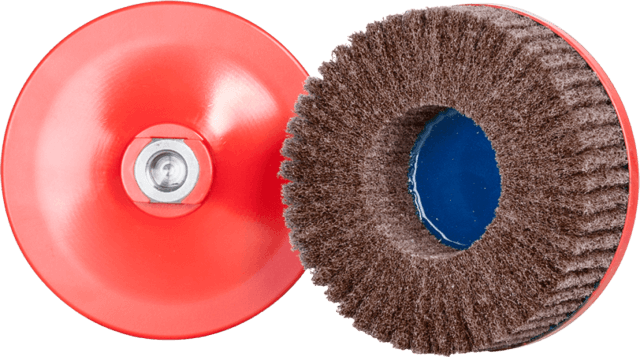

✔ Quick Change Grinding Head: Rotates 180° for rapid tool replacement, minimizing downtime.

✔ Versatile Material Processing:

Carbon steel

Stainless steel

Aluminum

Copper

Other non-ferrous metals

Technical Parameters:

| Specification | Details |

| Dimensions | 1250 mm × 750 mm × 1500 mm |

| Working Width | 1200 mm × 750 mm |

| Processing Thickness | 1–150 mm |

| Vacuum Suction Air Capacity | 1000 m³/h |

| Disk Brush and Sandpaper Speed | 500–1400 r/min |

| Disk Brush Size | φ 162 mm |

| Sandpaper Tray Size | φ 150 mm |

| Vacuum Platform Size | 300 mm × 300 mm |

| Grinding Head Power | 0.75 kW |

| Upper Platform Workpiece | 1000 mm × 750 mm |

| Grinding Head Quantity | 2 |

| No Platform Artifacts | 1400 mm × 1400 mm |

| Cantilever Operating Range | 1400 mm × 360° |

Standard Inclusions:

Vacuum suction table unit for clean and safe operation.

Ergonomic design for manual handling, reducing operator fatigue.

Adjustable grinding head for varying processing needs.

Applications:

This machine is perfect for:

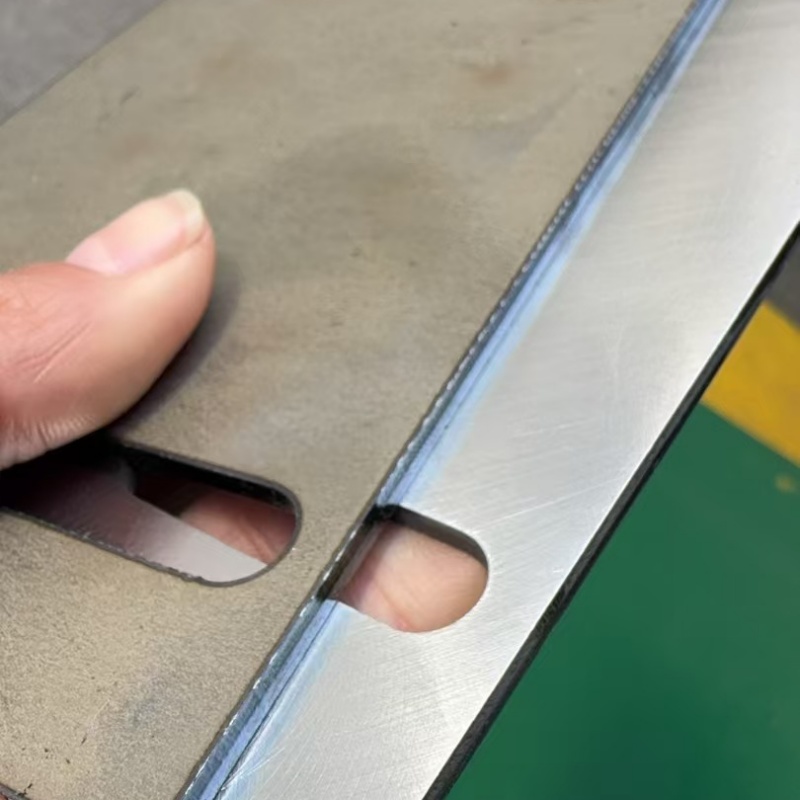

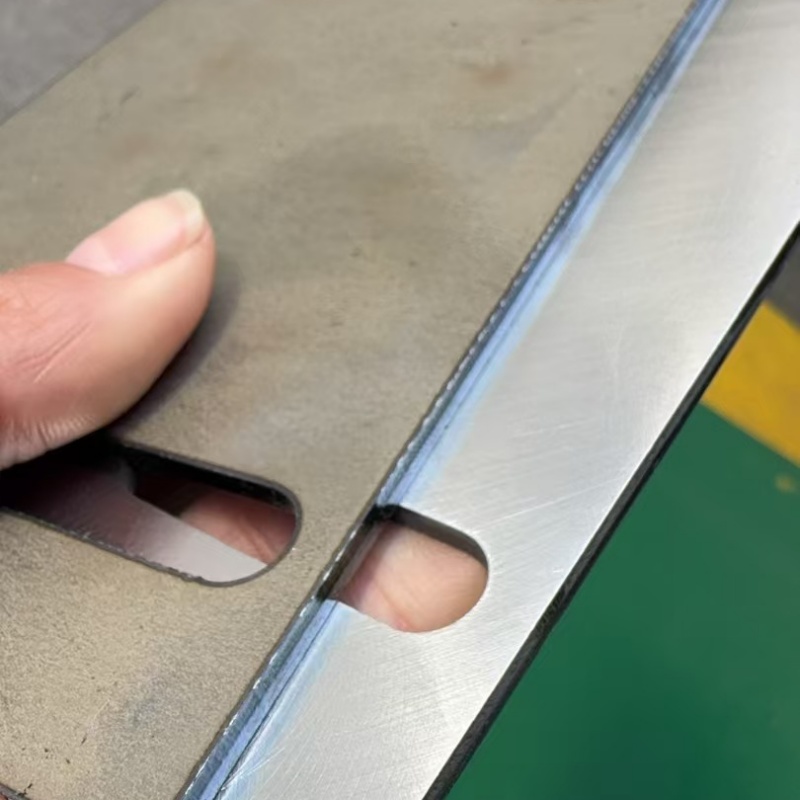

Metalworking: Deburring, edge rounding, and polishing for a wide range of metals.

Woodworking: Surface finishing and edge refinement.

Plastics Processing: Smooth finishing of non-metal materials.

How It Works:

Place the workpiece on the vacuum suction table (300 mm × 300 mm size) or upper platform (1000 mm × 750 mm).

Adjust the grinding head for the required process, utilizing the quick-change function for efficiency.

Manually operate the polishing arm with light pressure to achieve desired results.

The built-in vacuum system collects dust and debris, ensuring a clean workspace.